The Lifecycle of Working with NRTC

NRTC Automation will help you get started on the important automation journey to improve production throughput and minimize downtime.

Automation is directly associated with an increase in productivity, efficient utilization of resources, improved safety, enhanced product quality, and reduced labor.

Increased productivity and higher output are the biggest factors that justify our push for industrial automation. Additionally, automated systems deliver consistency during the manufacturing process. That leads to greater control of product quality.

NRTC is your ideal automation partner. Our wide range of services can help you make the most of what automation offers.

Keep reading to find out more about the lifecycle of working with NRTC Automation.

Lifecycle of working with NRTC

Automation

At NRTC, we are driven by our mission, which is to help manufacturers maneuver through the world of automation.

We have a rich history in the industry, which dates back more than a decade ago. Ever since our operations started, we have been driven by the same underlying goal to deliver high-value industrial automation and manufacturing solutions to our customers.

Over the years, we have built our presence in Alabama, Windsor, Canada, and Detroit to serve our customers across North America.

Core services we specialize in

At NRTC Automation, we believe in specialization in crucial areas. That is what makes us better at what we do. We commit specific teams to customer projects to deliver impeccable results.

We offer the following services:

· Decommissioning and tear-outs

· Customized work cells for automated production lines

· Service part manufacturing for all industries

You can also get in touch with us for other services like robot refurbishing, engineering, training, and more.

At NRTC Automation, we have a stiff definition of success. We consider a project successful when it no longer has room for improvement, there are no riddles that need salvaging, and customer satisfaction can no longer get any better.

We are well-equipped and skilled to effectively handle your upcoming industrial automation project. By the time we close up on the project, you can expect more than 200 percent improvement in throughput and capacity.

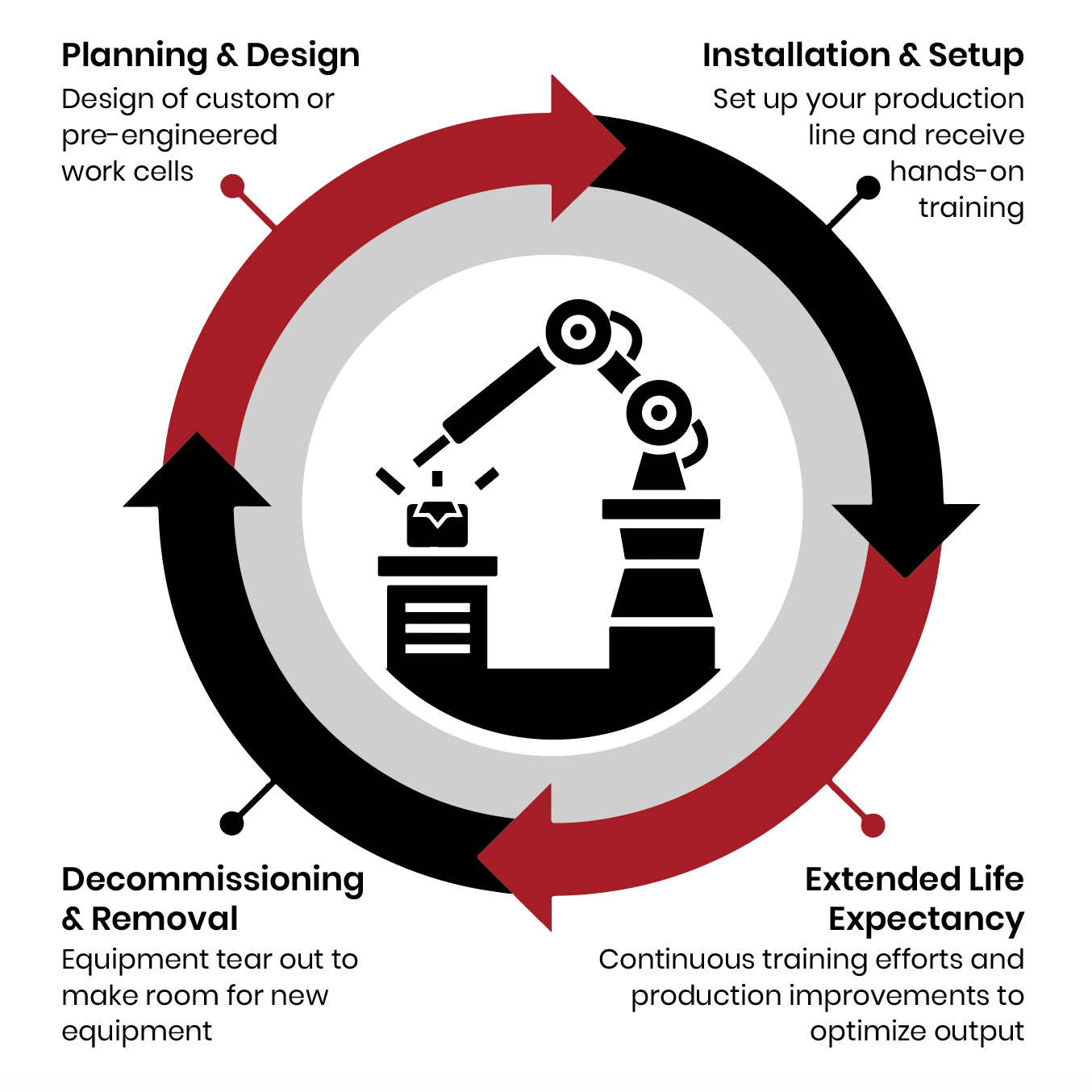

NRTC Automation lifecycle explained

At NRTC, we have positioned ourselves as your full-service automation provider. When you engage us for your automation needs, you can expect full lifecycle support. That means we start from the ground up until the final phase of automating the production line. We handle all activities from troubleshooting, hiring, training, and eventually tear out. In other words, we help you manage your projects and grow your manufacturing business from start to finish.

Here is a detailed look at our lifecycle.

PHASE 1 – PLANNING AND DESIGN

We don’t start your industrial automation project blindly. Instead, we determine how to ensure your success at the planning and design stage, leveraging the requirements gathered from you to come up with a customized robotic work cell.

Our technicians will take you through everything that’s needed to develop a work cell suited to your needs.

We want to make sure that you have an easy time getting started on the journey to automating your operations. For that reason, we invite you to schedule a free consultation with us to curve the path for efficient manufacturing.

PHASE 2 – INSTALLATION AND SETUP

Once we have the plan and design ready, we immediately get started on bringing the solution to life. Our team of experts will handle the installation process to allow you to continue operations uninterrupted.

After completing the installation and setup, we’ll even help you find the right people to run the work cell.

Upon your request, we will scout for qualified technicians for the automated line. Additionally, we also offer personalized robotics training for your staff to upskill them as needed.

PHASE 3 – ONGOING OPERATIONAL SERVICES

We want to make sure that your equipment is always running smoothly. Thus, at the extended life expectancy phase, we provide services that ascertain uptime. These include services such as industrial maintenance, troubleshooting, robot refurbishing, and repairs.

Our aim is to make sure that you continually operate smoothly and meet your production goals each quarter. We use popular brands like Lincoln Electric, KUKA, and ATI to ensure you have minimal downtime with effective equipment.

PHASE 4 – DECOMMISSIONING AND REMOVAL

At this rate, your company continues to grow and may reach a time when current machinery no longer meets your needs or you are ready to move onto a different project. When that happens, we are available to help you with the decommissioning process.

We buy used assets and recycle equipment to create a broom-ready factory while helping you recoup the initial value of your investment and extend the life of equipment you no longer need. Doing so allows you to easily move on to your next project. Even with that, we can help with the automation requirements.

NRTC has decommissioned facilities for top automotive manufacturers with a 100% on-time success rate. Contact us today to get started on your next project.

NRTC IS YOUR TRUSTED AUTOMATION PARTNER

NRTC Automation seeks to help transition your production line to the next level. We offer services that cover a wide range of industries, be it aerospace, plastics, automotive, and any other.

Contact us today to start engaging you in our revamped automation lifecycle.