NRTC AUTOMATION BLOG | INDUSTRIAL ROBOTS AND AUTOMATION

The Automation and Manufacturing Industry Labor Shortage Explained with Possible Solutions

The automation and manufacturing industry in the United States is currently facing a significant labor shortage. As technology advances and companies seek to increase productivity and efficiency, the demand for skilled workers is growing. This article explores the reasons behind the labor shortage and presents potential solutions to address this critical challenge.

Did you know? If you need skilled-labor talent, NRTC Automation offer Engineering Contract Services to fill your shortages. Contact us for more information.

The automation and manufacturing industry in the United States is currently facing a significant labor shortage. As technology advances and companies seek to increase productivity and efficiency, the demand for skilled workers is growing. This article explores the reasons behind the labor shortage and presents potential solutions to address this critical challenge.

Did you know? If you need skilled-labor talent, NRTC Automation offer Engineering Contract Services to fill your shortages. Contact us for more information.

Understanding the Labor Shortage:

Several factors have contributed to the labor shortage in the automation and manufacturing industry. Firstly, the rapid advancement of automation technologies has increased the demand for specialized skills and knowledge. This requires workers to continuously update their expertise, causing a skills gap between the existing workforce and the evolving job requirements.

Secondly, a significant portion of the current manufacturing hands-on workforce is nearing retirement age. As experienced workers exit the industry, there is a lack of qualified individuals to replace them, more specifically to the expert level capability. Additionally, negative perceptions about manufacturing jobs among younger generations and a decline in vocational training programs, and an increased desire for a computer-based work environment, have further exacerbated the shortage.

Consequences of the Labor Shortage:

The labor shortage in the automation and manufacturing industry has serious consequences for the United States. Companies face challenges in meeting production demands, which can result in delayed deliveries, increased costs, and potential loss of business. The shortage also hampers innovation and competitiveness, as businesses struggle to adopt new technologies and processes without the proper talent for development and execution. Ultimately, the overall economic growth of the country could be hindered if this issue remains unaddressed.

Solutions to Overcome the Labor Shortage:

To tackle the labor shortage, a multifaceted approach is needed. Here are a few potential solutions:

Promoting Manufacturing as an Attractive Career Choice: Efforts should be made to reshape the perception of manufacturing jobs and highlight the rewarding and high-tech aspects of the industry. Collaborations between educational institutions, industry associations, and businesses can help create awareness and generate interest among younger generations.

Enhancing Vocational Training: Investing in vocational training programs can equip individuals with the necessary skills for automation and manufacturing jobs. By partnering with industry experts, educational institutions can offer specialized courses and apprenticeships to bridge the skills gap effectively.

Encouraging Reskilling and Upskilling: Existing workers should be provided with opportunities for continuous learning and development. Employers can offer training programs to upgrade their employees' skills and adapt to evolving technologies, ensuring a competent and agile workforce.

Strengthening Industry-Academic Partnerships: Collaboration between academia and the industry is crucial to align educational curricula with industry needs. Establishing apprenticeship programs, internships, and research collaborations can create a seamless transition from education to employment.

Embracing Automation Technologies: Leveraging automation technologies can help offset the labor shortage by improving productivity and efficiency. Companies should invest in state-of-the-art machinery and robotic systems to streamline operations and reduce dependency on manual labor.

The labor shortage in the automation and manufacturing industry poses a significant challenge to the United States. By promoting manufacturing careers, investing in vocational training, facilitating reskilling/upskilling, fostering industry-academic collaborations, and embracing automation, the nation can overcome this shortage and ensure long-term growth and competitiveness.

NRTC Automation offers solutions to help bridge the gaps you may have on your team. Look to us to offer highly skilled, dependable, and knowledgeable workforces to suit your needs. Check out our Engineering Contract Services webpage for more information or contact us here.

A Journey Through the History of Parts Manufacturing in North America

The history of parts manufacturing in North America is a tale of innovation, industrialization, and technological advancements. From humble beginnings, to becoming a global powerhouse, this sector has played a vital role in shaping the continent's economic landscape.

If you need parts, NRTC Automation will manufacture any part based on your custom specifications and volume needs. We offer service parts manufacturing for any industry, servicing automotive, aerospace, and food production to name a few.

The history of parts manufacturing in North America is a tale of innovation, industrialization, and technological advancements. From humble beginnings, to becoming a global powerhouse, this sector has played a vital role in shaping the continent's economic landscape.

This article will delve into the significant milestones and key contributors to the evolution of parts manufacturing in North America.

Did you know? If you need parts, NRTC Automation will manufacture any part based on your custom specifications and volume needs. We offer service parts manufacturing for any industry, servicing automotive, aerospace, and food production to name a few. We will configure a work cell specifically for your company, house production in one of our facilities, and build parts based on the quantity you’ve defined. Contact us for more information.

Origins and Early Development:

Parts manufacturing in North America can be traced back to the late 18th century when the Industrial Revolution was gaining momentum. The United States and Canada initially relied on skilled artisans who crafted components by hand. However, as demand increased, the need for mass production became evident, and the idea of “automation” was born.

Mass Production and the Assembly Line:

One of the pivotal moments in the history of parts manufacturing was the introduction of the assembly line. Henry Ford’s revolutionary assembly line in 1913 revolutionized the manufacturing process, allowing for rapid and cost-effective production. By breaking down the complexity of building an automobile into smaller, standardized, and repetitive steps, Ford's system accelerated productivity and lowered costs, setting a benchmark for the industry.

Automotive Manufacturing:

The automotive industry has been a driving force in the development of parts manufacturing in North America. Detroit, often referred to as the "Motor City," became the epicenter of automobile production in the early 20th century (pssst… Did you know that NRTC Automation operates a full-service location in Fraser, MI, a suburb just outside of the Detroit City limits?). Major automakers such as General Motors, Ford, and Chrysler established extensive manufacturing facilities, leading to the growth of an entire ecosystem of parts suppliers and manufacturers.

World Wars and Industrial Expansion:

Both World War I and World War II played a significant role in the expansion of parts manufacturing. The need for military equipment and vehicles prompted the establishment of new factories and accelerated technological advancements. These wars propelled North America's parts manufacturing sector to new heights, leading to increased capacity, improved processes, and enhanced quality control measures.

Technological Advancements:

The latter half of the 20th century witnessed remarkable technological advancements that transformed parts manufacturing. Computer Numerical Control (CNC) machines, which utilized computer programming to control machining tools, revolutionized precision manufacturing. Robotics and automation further streamlined production processes, enhancing efficiency, and reducing human error.

Outsourcing and Globalization:

In the late 20th century, the North American parts manufacturing landscape experienced a shift as companies began to outsource production to countries with lower labor costs. While this trend led to job losses in some regions, it also paved the way for increased specialization and the emergence of high-tech manufacturing hubs.

Reshoring and the Digital Age:

In recent years, there has been a growing trend of reshoring, with companies bringing manufacturing operations back to North America. Factors such as rising wages in overseas markets, supply chain disruptions, and a focus on quality control have contributed to this shift. Furthermore, the digital age has enabled advancements such as additive manufacturing (3D printing), allowing for rapid prototyping and customization.

The history of parts manufacturing in North America is a testament to human ingenuity and industrial progress. From the early days of skilled artisans to the era of mass production and technological advancements, this sector has continuously evolved to meet changing demands. The automotive industry, world wars, globalization, and the digital age have all played pivotal roles in shaping the landscape of parts manufacturing. As we move into the future, the industry is poised to embrace new technologies and innovations, ensuring North America remains a prominent player in this vital sector.

Look to us, NRTC Automation, to be your North American based parts manufacturing source. We’re best known for our professionalism, customer-oriented approach, and dedication to quality. Have other industrial projects you need assistance with? On top of parts manufacturing, we offer automation, decommissioning and engineering contract services, to name a few.

Let’s work together – contact us here to get started.

Automation and Robots - Friends not Foe

There can be a lot of misconceptions about industrial robots and their place in the manufacturing workplace. They can have a bad reputation of replacing jobs and flooding the job market with workers now deemed useless.

Here at NRTC Automation, we have a different perspective on robots, and how they can improve, not destroy, your manufacturing team and process.

There can be a lot of misconceptions about industrial robots and their place in the manufacturing workplace. They can have a bad reputation of replacing jobs and flooding the job market with workers now deemed useless.

Here at NRTC Automation, we have a different perspective on robots, and how they can improve, not destroy, your manufacturing team and process. Read on to learn more about why we consider robots friends, not foe.

Robots Create Jobs

It’s easy to believe what we see in science fiction: robots taking over the world, and thus taking all of our jobs. But that just isn’t the case. Total automation just isn’t possible, and even though there have been several attempts to remove the human factor as much as possible, they have resulted in failure.

Robots are actually creating a new classification of jobs as industrial automation grows. We see workers that are brought in to develop artificial intelligence and analytics software. Additionally, worker augmentation is trending in the industry, working remotely to control equipment. This shift is replacing in-class training with in-field training and support, and workers are having access to resources quickly at the tips of their fingers.

NRTC Automation offers robotic training programs aimed at educating your team with the latest robots and equipment from all major manufacturers. From basics, such as programing, to advanced troubleshooting, NRTC can empower your team to solve issues and work with today’s state-of-the-art robotics.

Robots Keep You Safe

Industrial manufacturing has been historically a dangerous and dirty occupation. Before OSHA was founded in 1970, and the EPA in the same year, there were very few universal safety standards in place. Along with a lack of labor laws, and little safety concerns for workers, there was also a severe lack in controls and regulations, and factories could produce quite a bit of pollution.

Implementing robots into workplaces and giving them tasks that before required heavy labor and dangerous conditions protects humans from injury, exposure to unsavory elements, and even death. Efficient robotics have reduced pollution, as well as humans' direct content with pollution-producing substances, and have helped to create a safer environment both inside and outside the workplace.

Robots Save You Money

Implementing robots into your manufacturing processes will not only increase production capacity, but it will also improve both efficiency and product quality while saving you money. Along with keeping workers safer, implementing robotics can help prevent the cost of work injuries which was over $171 billion in the U.S. economy in 2019.

Automation can also streamline production, with software computing the best path for robots to take, and reducing time and energy spent. Changes can be made quickly, even in small spaces, and don’t require retraining of staff. A reduction in time and energy equates to additional cost savings.

With robots and automation, it is easy to ramp-up and increase production at the drop of a hat. NRTC customers alone have seen a 200 percent increase in throughput from implementing our turnkey weld cell solutions to their production processes. Implementing robotics lets companies stay competitive in an ever-changing global economy and increase production and ROI.

Robots are our Friends

Industrial robots are here to stay, and that isn’t a bad thing. With the innovation and expansion of automation and technology, robotics are showing not only how they can improve production, but also keep workers safe, and increase savings and profits.

NRTC can help you integrate robots into your manufacturing with turnkey weld cells and industrial automation solutions. Contact us today to learn more.

Key Components to Increase Your Production Line’s Efficiency

A key to a successful manufacturer’s production line is efficiency. Ensuring an efficient production line guarantees higher returns, less waste, and a high standard of production quality. Taking steps to ensure that your production line stays efficient is an important part of the manufacturing process.

A key to a successful manufacturer’s production line is efficiency. Ensuring an efficient production line guarantees higher returns, less waste, and a high standard of production quality. Taking steps to ensure that your production line stays efficient is an important part of the manufacturing process.

Keep reading to learn what steps you can implement to keep inefficiency at bay and your production line running smoothly and performing at its highest caliber.

Automation

Automating a production line is one of the easiest steps you can take to improve the efficiency of your production line. Implementing industrial robots and solutions like turnkey weld cells allow your production line to seamlessly blend with your workers, producing a higher-functioning production process.

Automation keeps your company in line with current competition and allows businesses to grow in scale and capacity with ease. Investing in automation can unlock efficiencies, and also keep businesses competitive with lower labor cost markets overseas. Without this, manufacturing business can and do shift from the US to an overseas market.

Maintenance of Robots and Equipment

A production line is only as good as its machines, so it’s vitally important to keep robots and production equipment well maintained. Not only should a daily, weekly, and monthly maintenance and tune-up be kept, but additional reconditioning and refurbishment should be considered should a production line show signs of slowing down or using more energy than usual.

Reconditioning or refurbishing can extend the life of your robot and breathe new life into the machinery. During a refurbishment, robots are cleaned, broken parts are repaired, and testing is done to ensure that the machine is running top of its game.

Refurbishment can even go as far as returning a robot back and restoring it to factory new settings, along with a bright new paint job to match the squeaky clean like-new interior.

Training

Keeping your employees trained and at the top of their game is just as important as maintaining machinery and industrial robots. Employees are the heart of the company, and not only do they maintain automation production day-to-day but they will often be the first point of contact when a problem arises.

Continual training on new safety measures, production hardware and software updates, and the latest OSHA safety measures ensure efficiency in the workplace. Keeping robots operating smoothly and the floor safe limits downtimes on both a machine and worker front.

Product Quality

Did you know poor quality materials can slow your production line? Not only do low quality materials often create more waste, but they can create waste through products that don’t meet a high-quality standard.

With supply chain issues often being a source of frustration, especially in a post-Covid world, it’s important to find a reliable supplier, and stick with them, even if there might be a few delays. Ensuring that your product is of the highest quality keeps customer’s happier, and your companies reputation in good standing.

NRTC Automation

NRTC Automation is trusted by companies worldwide to provide comprehensive industrial automation and manufacturing services. We’ve worked with top manufacturers for more than a decade, supplying them with engineering contract services, turnkey weld cells, industrial robot refurbishment, and more.

Contact us today and schedule your free consultation, and learn more about all the services that we offer.

Three Green Trends in Industrial Manufacturing

Green manufacturing is an important topic at the forefront of industrial manufacturing. Companies are constantly looking for ways to reduce waste and positively impact both the environment and their businesses.

Green manufacturing is an important topic at the forefront of industrial manufacturing. Companies are constantly looking for ways to reduce waste and positively impact both the environment and their businesses.

As companies look toward greening their manufacturing processes, here are three trends you can look for in the industry.

Using Renewable Energy

The idea of renewable energy isn’t a new one. Solar, wind, and water-powered energy exists, but how are companies harnessing them?

In Europe, companies can purchase renewable energy certificates to offset their emissions. These certificates or credits are known as RECs equate to an amount of power generated from a green, renewable source. Purchased in megawatt hours, companies can strategize using wind, hydro, or solar to help move their company towards carbon neutrality.

Improving Emissions through Automation

Another way companies can reduce their carbon footprint is to look at their own emissions, and see what steps can be taken in order to reduce them. Automating production can be a tool in not only reducing your emissions, but monitoring them more closely.

When industrial production is automated, businesses are able to automatically collect data and run reports on energy, emissions, and costs. A smooth production line overall creates less downtime, and that can equate to fewer losses of resources.

Additionally, adding electric control modules, or ECMs, to your tool kit can help to manage and monitor the energy used from machines, lights, and more. You’ll be able to tell how much electricity a machine is using, and from there make decisions about upgrading or retiring machinery or lighting.

Reducing energy consumption can not only save you money but directly affect the environment in a positive way, reducing the use of additional resources.

Producing Energy In-House

Producing energy in-house, specifically solar, is another route many companies are taking in the process of greening their industrial manufacturing. The German manufacturer ABB opened a facility in 2019 that can power itself on sunny days.

The facility built in Luedenscheid, Germany can produce 1100 MW hours of power each year. That’s enough to power 340 homes for a year! We can expect to see more industrial manufacturing moving towards creating their own solar power in the upcoming years, in an effort to not only continue to green their processes but continue to save money.

Smaller Steps

While we highlighted these three trends, there are many steps companies around the world are taking in order to green their manufacturing. Keeping machines conditioned and running smoothly cuts down on energy waste, and ensures smooth production.

When it’s time to replace existing robots, consider selling to a business like our sister company HGR, which buys and sells industrial surplus, keeping it out of landfills. And purchasing a refurbished robot keeps the lifecycle of machinery extended and away from the dump.

Streamline and Refurbish with NRTC Automation

We also refurbish industrial robots here at NRTC, extending the life of your machine, and aiding you in reducing waste and saving money. NRTC also designs and produces turnkey weld cells, created with refurbished industrial robots. We have a focus on efficiency, maximum throughput, and minimal waste.

To learn more about our green automation solutions and refurbishment options, contact us today.

Signs Your Robot Needs Repair

Production lines rely on industrial robots to keep manufacturing on track and running smoothly. A breakdown or malfunction can put a wrench in production, and cause downtime and a loss of profits. Knowing the signs that your robot needs repair can keep things running smoothly and downtime at a minimum.

Production lines rely on industrial robots to keep manufacturing on track and running smoothly. A breakdown or malfunction can put a wrench in production, and cause downtime and a loss of profits.

Knowing the signs that your robot needs repair can keep things running smoothly and downtime at a minimum.

Read on to learn what signs to look for that might indicate your robot needs repair.

WASTING TIME AND ENERGY

Industrial robots are designed to make a production line more efficient, so if you notice that it might not be performing up to standard, this is a clear indicator that repair or maintenance may be needed. Watch for the robot’s movements and if there seems to be a delay, or if there are unnecessary gestures or motions, diagnosing issues and repairs should be on the docket.

NRTC Automation runs robots through at least 50 cycles so that we can observe movements, motions, and its ability to repeat each function. Observing this way allows for surface-level errors to be easily spotted, and we can create a checklist to problem shoot based on what errors arise.

INSPECT THE TEACH PENDANT

Teach pendants can offer one of the most straightforward indicators of an issue. A teach pendant, or teach box, is the control box for a robot’s programming. They are used to teach a robot the step-by-step processes that it will be required to perform and is usually handheld. Think of it as an educational gaming system.

If you think there might be an issue with your robot, consult the teach pendant and programming as one of the first steps in troubleshooting. There is valuable information in the system, and if there are any programming errors, they should show up on the pendant’s screen.

CHECK THE CHARGE

An easy checklist item when troubleshooting robot issues should be checking the batteries. Something as simple as a low or depleted battery can cause a variety of issues.

Keeping a robot’s batteries updated should be a part of routine maintenance, and logging install and replacement dates a part of normal documentation.

OVERHEATING

Robots and machinery, when running, produce heat, and there are standard temperatures to look for in motors and elements, such as the servo motor. If these are overheating, that can be a sure sign that your robot needs repairs.

ADDITIONAL TROUBLESHOOTING

Additional signs of repair to look for include the inability to upgrade properly, a lower than usual number of completed cycles, or connection errors. And when it comes down to it, no one knows your robots better than the people that work on them every day. If you or your employees think there might be a problem, it’s worth looking into it.

Prevention is Key

Routine maintenance, planning, and installing timely updates are all key to keeping a robot working at peak performance. NRTC Automation offers not only training but industrial robot refurbishing.

Reconditioning and refurbishing ensure your robot stays running smoothly and efficiently. Additionally, investing in maintenance and refurbishment is cheaper than replacing it with brand new equipment.

NRTC Automation robotic training programs work with your team to personalize hands-on training based on your needs and requirements. The end result is an empowered team with the confidence and skills to diagnose and repair robots in-house.

Designing Your Weld Cell - 3 Things You Need to Know

Robotic weld cells can help production lines increase productivity and efficiency, as well as keeping costs lower. While individual industrial robots can be great, weld cells are pre-engineered to run production according to a job specific need.

In a constantly evolving competitive economy, adding elements like robotic weld cells keep companies on the cutting edge and able to focus on efficiency. And with many production cells cutting down on waste, there is not only higher profit, but an increasingly better relationship with the environment.

There are important steps and processes to consider as you are designing a weld cell for a production line.

Continue reading to learn three things you need to know before designing your weld cell.

MAKE A PLAN

It seems like a simple and straightforward idea, but knowing exactly what your work cell needs to do is an important first step when designing. Asking questions like, “What will my work cell be producing?” is key to knowing exactly what parts to include in the cell, and how to program it.

Each work cell that is in existence has not only specialized parts, but unique programming to both the task and machine. Being as specific as possible in this early stage helps streamline building and programming, and ensures less down time as you start to design.

Part of making a plan should be developing an outline, including mapping out tasks before production and building begins. A solid outline will act as a framework for production, and make sure all steps of the automation process will be included.

PICK YOUR PLAYERS

Once a thorough plan is created with an outline, it’s time to select the industrial robots and parts for your weld cell. As you are searching for robots, there are a few important points that should be considered:

Robots' Reachability – This can determine the number of robots and spacing.

Payload Limitations – Consider what you are producing, and the weight and size limitations of the equipment you are selecting.

Precision Capabilities – Determining what you will be producing and the finer nuisances that might be needed can separate one robot choice from another.

End of Arm Tooling (EOAT) - Knowing what equipment you will need on the end of your robotic arm can help to narrow down purchasing options.

Cycle of Time – The speed of the robot is a good indicator for a production line’s efficiency and speed.

In considering what robots to select, a positioner also needs to be chosen. The positioner is what will hold or contain your product that is being manufactured. It can be mobile or fixed, with factors such as adjustable height and weight capacity being taken into consideration when selecting an option.

LAY IT ALL OUT

Once you’ve developed an outline, and selected your production equipment, it’s time to create a layout. This is the most important aspect of design, as you are figuring out the placement of both robots and positioners to achieve maximum efficiency.

Consider how your work cell will be laid out. Will it be in a linear fashion, or will it have turns, or changes in direction?

As you lay it out, make sure to think about not only how it will fit into a manufacturing facility, but how staff and employees will be positioned in the workflow. Safety is always the most important factor, and protecting and making sure employees are comfortable should be a top priority.

NRTC Automation Solutions

NRTC specializes in custom turnkey weld cells for manufacturers of all sizes. From startups to top automotive OEMs, all of our work cells are refurbished, ensuring turnkey automation that is ready-to-work and affordable.

For more information on our automation solutions, turnkey weld cells, and parts manufacturing, contact us or visit our website for more information.

Sculpturist Company Neoset Designs Utilizes Robots

NRTC specializes in turnkey solutions for businesses in the manufacturing industry, and it isn't every day we encounter the kind of company that our sister company iGAM recently worked with.

NRTC specializes in turnkey solutions for businesses in the manufacturing industry, and it isn't every day we encounter the kind of company that our sister company iGAM recently worked with.

When a customer purchases a robot it might be added to an existing assembly line, or it could be the start of production and streamlining for a newer company.

However, when we heard about iGAM robots being used to produce art, we had to know more.

NEOSET DESIGNS

Neoset Designs is a pioneer in using technology to create innovative and complex works of art. By using robots they are able to quickly produce their pieces and make their art pieces even more intricate. Their challenge before iGAM was being able to acquire high-quality, affordable robots to continue to create their art.

"Having equipment that is reliable is extremely important. It doesn't matter how good you think you are; at the end of the day, you need to be able to trust your machinery."

IGAM ENTERS THE PICTURE

Neoset was initially attracted to iGAM after their online marketplace was launched, consisting of industrial robots and machines. But soon they grew to appreciate iGAM’s dedicated sales staff, who were able to accommodate their boutique needs of just one or two purchases at a time.

All of iGAM’s products have a high level of care, and iGAM ensures all of their customers get first-rate equipment, as well as going the extra mile to make sure that Neoset was informed of any new robots or tools that would work well for any current or future projects they might be working on.

A BETTER END PRODUCT

Today, Neoset Designs uses five robots purchased from iGAM. These robots are cutting production time, and allowing Neoset to produce highly complex projects. For more information on this project and iGAM, and to see images of the large-scale, beautiful pieces Neoset produces, please visit the iGAM case study.

NRTC Supports the Robotics Industry

At NRTC, we focus on reconditioning and refurbishing robots to enhance your production line with affordable industrial automation. We also design, build, and engineer custom work cells to handle your specific application. Contact us today to learn more about our services.

The Lifecycle of Working with NRTC

NRTC Automation will help you get started on the important automation journey to improve production throughput and minimize downtime.

NRTC Automation will help you get started on the important automation journey to improve production throughput and minimize downtime.

Automation is directly associated with an increase in productivity, efficient utilization of resources, improved safety, enhanced product quality, and reduced labor.

Increased productivity and higher output are the biggest factors that justify our push for industrial automation. Additionally, automated systems deliver consistency during the manufacturing process. That leads to greater control of product quality.

NRTC is your ideal automation partner. Our wide range of services can help you make the most of what automation offers.

Keep reading to find out more about the lifecycle of working with NRTC Automation.

Lifecycle of working with NRTC

Automation

At NRTC, we are driven by our mission, which is to help manufacturers maneuver through the world of automation.

We have a rich history in the industry, which dates back more than a decade ago. Ever since our operations started, we have been driven by the same underlying goal to deliver high-value industrial automation and manufacturing solutions to our customers.

Over the years, we have built our presence in Alabama, Windsor, Canada, and Detroit to serve our customers across North America.

Core services we specialize in

At NRTC Automation, we believe in specialization in crucial areas. That is what makes us better at what we do. We commit specific teams to customer projects to deliver impeccable results.

We offer the following services:

· Decommissioning and tear-outs

· Customized work cells for automated production lines

· Service part manufacturing for all industries

You can also get in touch with us for other services like robot refurbishing, engineering, training, and more.

At NRTC Automation, we have a stiff definition of success. We consider a project successful when it no longer has room for improvement, there are no riddles that need salvaging, and customer satisfaction can no longer get any better.

We are well-equipped and skilled to effectively handle your upcoming industrial automation project. By the time we close up on the project, you can expect more than 200 percent improvement in throughput and capacity.

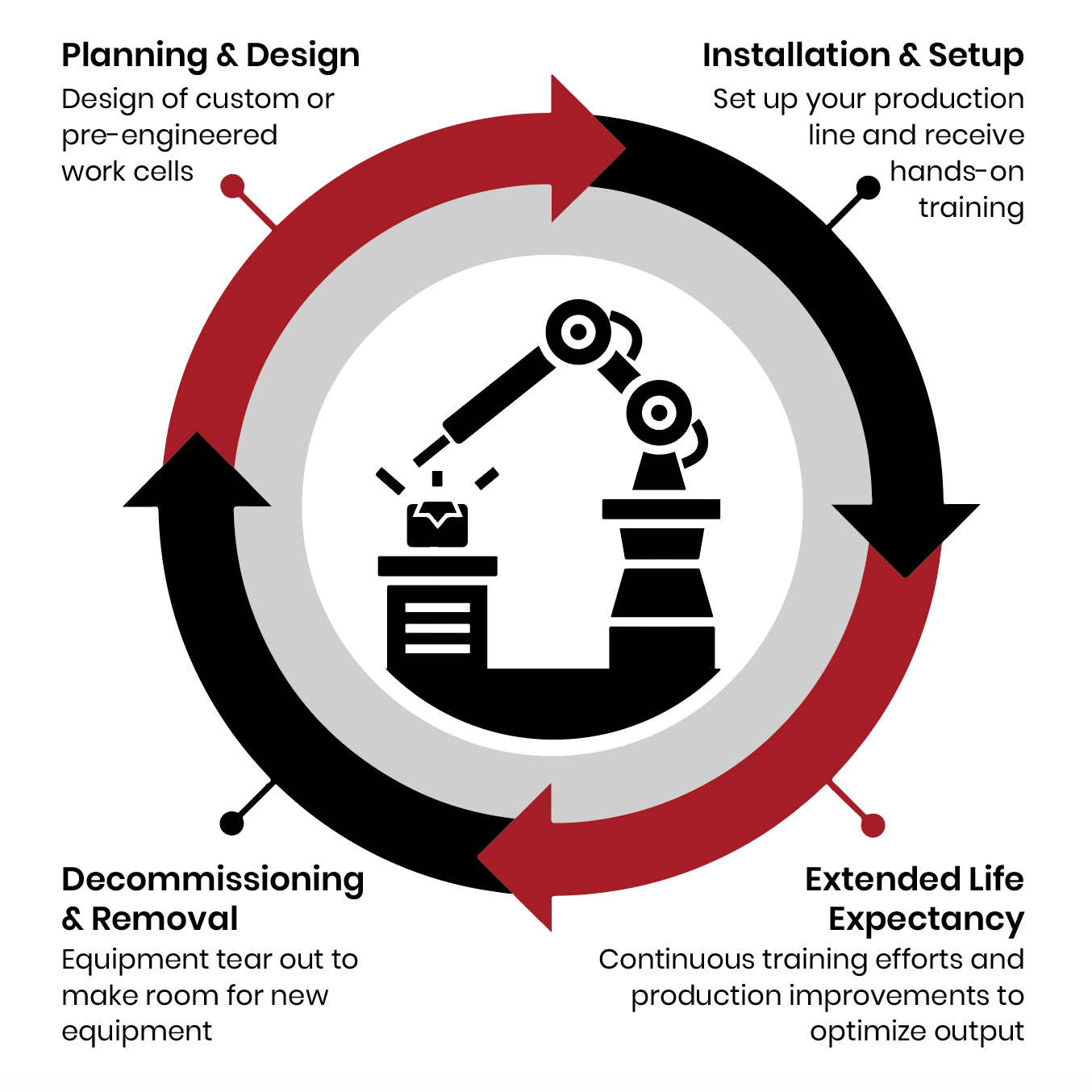

NRTC Automation lifecycle explained

At NRTC, we have positioned ourselves as your full-service automation provider. When you engage us for your automation needs, you can expect full lifecycle support. That means we start from the ground up until the final phase of automating the production line. We handle all activities from troubleshooting, hiring, training, and eventually tear out. In other words, we help you manage your projects and grow your manufacturing business from start to finish.

Here is a detailed look at our lifecycle.

PHASE 1 – PLANNING AND DESIGN

We don’t start your industrial automation project blindly. Instead, we determine how to ensure your success at the planning and design stage, leveraging the requirements gathered from you to come up with a customized robotic work cell.

Our technicians will take you through everything that’s needed to develop a work cell suited to your needs.

We want to make sure that you have an easy time getting started on the journey to automating your operations. For that reason, we invite you to schedule a free consultation with us to curve the path for efficient manufacturing.

PHASE 2 – INSTALLATION AND SETUP

Once we have the plan and design ready, we immediately get started on bringing the solution to life. Our team of experts will handle the installation process to allow you to continue operations uninterrupted.

After completing the installation and setup, we’ll even help you find the right people to run the work cell.

Upon your request, we will scout for qualified technicians for the automated line. Additionally, we also offer personalized robotics training for your staff to upskill them as needed.

PHASE 3 – ONGOING OPERATIONAL SERVICES

We want to make sure that your equipment is always running smoothly. Thus, at the extended life expectancy phase, we provide services that ascertain uptime. These include services such as industrial maintenance, troubleshooting, robot refurbishing, and repairs.

Our aim is to make sure that you continually operate smoothly and meet your production goals each quarter. We use popular brands like Lincoln Electric, KUKA, and ATI to ensure you have minimal downtime with effective equipment.

PHASE 4 – DECOMMISSIONING AND REMOVAL

At this rate, your company continues to grow and may reach a time when current machinery no longer meets your needs or you are ready to move onto a different project. When that happens, we are available to help you with the decommissioning process.

We buy used assets and recycle equipment to create a broom-ready factory while helping you recoup the initial value of your investment and extend the life of equipment you no longer need. Doing so allows you to easily move on to your next project. Even with that, we can help with the automation requirements.

NRTC has decommissioned facilities for top automotive manufacturers with a 100% on-time success rate. Contact us today to get started on your next project.

NRTC IS YOUR TRUSTED AUTOMATION PARTNER

NRTC Automation seeks to help transition your production line to the next level. We offer services that cover a wide range of industries, be it aerospace, plastics, automotive, and any other.

Contact us today to start engaging you in our revamped automation lifecycle.

A Look into the Future: What Will the Robotics Industry Look Like in 10 Years?

The robotics industry is changing at a rapid rate, and the future is looking bright with highly-efficient automation.

The robotics industry is changing at a rapid rate, and the future is looking bright with highly-efficient automation.

The use of robots in and beyond the industrial sector was considered science fiction just a few decades ago. Today, most of what was thought impossible is a reality. Industrial robots have become an integral part of manufacturing processes, shielding humans from dangerous processes and infusing efficiency in the sector.

More companies are continually embracing robotics, making the industry's future much brighter. But it’s not just the big names that are making the industry grow. Contrary to expectations, small companies have played a central role in giving industrial robots various applications.

Read to the end to understand what the future holds for the robotics industry.

Are robots going to take over the world?

No one can effectively have a conversation about robots without discussing whether they will take over the world.

To appreciate the need for this conversation, we must start by acknowledging that robots are all around us. There is no need to look far before noticing it. It starts with basic conversational bots like Siri and Alexa, to complex ones such as those used to assemble vehicles in more than half the time it would take by hand.

Without beating around the bush, robots will replace many human jobs, just like humans and horses were replaced by modern farming equipment. However, in a positive twist of events, humans will play a vital role in adding value to the robotic investment.

Humans and robots are meant to have a complementary relationship. As robots take away repetitive tasks, we will be freed to study and improve our skills for more mind-engaging jobs. The involvement of artificial intelligence is deemed to help us become smarter and improve our decision-making process.

Using robots for factory automation will replace some jobs and create new ones. Some of the positions that are likely to come up include:

Advanced data scientist

Design thinker

AI trainer

Privacy and trust manager

Virtual reality manager

Additionally, work would be more flexible since people have seamless access to tools and information required for collaboration. In other words, the future of robots does not involve replacing human jobs. On the contrary, the two would jointly work together.

How robots will evolve

With the evolution of robotic technology, it has become possible for robots to learn independently. For instance, the robot could be built now to pick and place items. However, it could use vision to figure out its own programming based on the data gathered.

A key trend to pay attention to is the concept of collaborative robots. These robots can safely work in the same environment as human employees in a shared workspace. The robotic industry is headed to a future where more collaborative robots will be the norm.

The idea behind collaborative robots is to use them on repetitive, menial jobs while employees take care of thought-intensive works. Human worker leverages their problem-solving skills in conjunction with the uptime and accuracy of collaborative robots to ensure top-quality results.

Working collaboratively with humans opens up more opportunities for robotic applications. Due to its potential, the market for collaborative robots will continue growing as more industries appreciate the technology's benefits.

Robot safety will continue to shape the industry's future

Safety is one of the key things that most people sourcing for used industrial robots often consider. There is emerging marketing of safety sensors dedicated to making sure humans can work with robots. Thanks to machine vision, it is gradually becoming possible for robots to "see" activities taking place in their workspace.

Machine vision will continue to play an important part in ensuring robots are involved in different manufacturing processes. Concepts such as multispectral, 3D embedded vision, and hyperspectral imaging are the future of industrial robots. When combined with deep learning and artificial intelligence, industrial robots are empowered to keep pace with human workers.

Companies like FANUC are already making robots that can learn on their own. That shows this bit of the future is more of a reality than a theoretical expectation.

Experts estimate that the robotic industry will register a 175% growth over nine years. That means innovators will continue to try to outdo each other, effectively driving the growth of modern technologies. Such developments will help make collaborative robots safer.

NRTC SUPPORTS THE FUTURE OF THE ROBOTICS INDUSTRY

At NRTC, we focus on reconditioning and refurbishing robots to enhance your production line with affordable industrial automation. We are committed to extending your robot's life while ensuring it operates at the highest level possible. We also design, build, and engineer custom work cells to handle your specific application. Contact us today to learn more about our services.

4 Ways to Take Your Production Line to the Next Level Manufacturing

Implement these measures on your production line to increase productivity and efficiency, growing your business in the process.

Implement these measures on your production line to increase productivity and efficiency, growing your business in the process.

Process improvement is one of the most important undertakings for business owners. It gives you an idea of how your business is performing and what is needed to improve in particular areas.

By streamlining your production process, you can set yourself up for success. It puts you on the right path towards expanding your business operations for more rewarding projects.

One of the most important ways to grow your manufacturing business is to make the most of what factory automation has to offer. The following are four effective ways for taking your production line to the next-level manufacturing.

Effective ways to take your production line to the next level

#1: Improve existing workflows

It is nearly impossible to talk of moving from point A to B if you don’t know what is going on at point A currently. That is why every project to enhance your processes begins with a detailed look into what is taking place at the moment.

Evaluating your workflow can help reveal some of the time-wasters on the job. These include unnecessary tasks on the line, repetitive labor force, and old equipment.

Tip: Always keep an open mind when evaluating your business model and production line. Even if it is something that you helped develop, all processes deserve review and can be optimized for improvements.

According to Camuda, 97% of businesses that engage in workflow automation leverage the benefits of digital transformation. Furthermore, 36% of businesses are already adopting solutions required to automate workflows.

You can initiate the improvement process by seeking feedback from your employees on how they feel about current procedures. The goal would be to find out what is working and what isn’t. Such information would guide you to optimize procedures for a better working experience.

Look at whether you have the right people with the right skills properly matching their roles. That involves a clear definition of your objectives on the production line.

More importantly, adopt tools and technology needed for industrial automation. Make sure that you are using relevant machinery for your specific applications.

#2: Prioritize maintenance

Production lines may have increasingly poor performance over time because they are not well-maintained. Running operations without maintenance can prove dire to the business as you constantly struggle with unplanned downtime due to machinery repairs.

For that reason, it is crucial to have a maintenance schedule. Schedule maintenance in intervals to prevent overlapping maintenance on similar sections of your production line.

Plant maintenance is one of the most important undertakings on your production line. That’s because 18% of operator errors come about due to unscheduled equipment downtime.

Begin the maintenance process by training all your operators and maintenance technicians. That gives them a technical understanding of what needs to be done under certain conditions. Also, set fixed dates and intervals when all maintenance works would be done.

#3: Modernize processes and technologies

It is impossible to take the production line to the next level of manufacturing while still running on old technologies.

We live in a time when companies are scrambling to make the most of smart technologies like the Internet of Things (IoT). The technology involves networking all your core equipment to communicate with each other. Such communication is achieved through software, sensors, and technologies that foster data exchange.

Modernizing your business processes involves looking into how new software can help with planning, monitoring, and inventory control. Furthermore, it entails either upgrading or replacing existing machinery and equipment.

#4: Diversify the product range

Taking your production line to the next manufacturing level requires you to think out of the box and come up with new product ranges. Releasing one product to the market may prove challenging to your growth efforts. Diversification of your product line is the key to achieving unprecedented growth levels.

That does not mean introducing just any product. Align the new products with existing ones for optimal efficiency, such as:

Products that are made of the same materials

Products that use the same machines

Products that are used by the same or similar markets

There are different techniques for product diversification, including renaming, repackaging, resizing, and brand extension.

It is important to think of what you do better than competitors as you diversify. That gives you an idea of your current strengths and how you would extend the same in the new products.

In the long run, having various products on your manufacturing line helps increase profits and tremendously create brand awareness.

NRTC IS YOUR GATEWAY TO TAKING THE PRODUCTION LINE TO THE NEXT LEVEL

As you try to learn how to adopt industry 4.0 to enhance your production line, you need a partner who knows how to move toward continual growth. AT NRTC, we are all about automating your production line with the latest technologies. You can count on us for different services, including industrial robot refurbishing, service parts manufacturing, robotic training, among others.

Schedule a free consultation today to get started.

10 Qualities the Best Industrial Operators Tend to Have

What is an industrial operator and what makes an operator successful? Find out with NRTC Automation.

What is an industrial operator and what makes an operator successful? Find out with NRTC Automation.

An industry operator is a crucial employee of any industry set up, as he or she is responsible for setting up, operating, and maintaining a safe and high-functioning production line by ensuring that everything is running smoothly and at the required capacity.

An ideal industrial operator is said to have strong attention to detail and be an excellent team worker. Learn more about the other qualities an industrial operator must have to be successful.

Top 10 qualities the best industrial operators tend to have

Hiring a skilled and reliable industrial operator is a great first step to ensuring seamless industrial operations and preventing different kinds of avoidable accidents or injuries on the job.

Staffing industrial workers in a production or manufacturing plant will always have its own unique challenges. However, you can always partner with NRTC Automation to help you hire and train the ideal industrial operator.

Let’s look at some of the top qualities you should look for in your next industrial operator.

1. Excellent communication skills

As an industrial operator, one is expected to work closely with other teams in the production chain. Good communication skills and willingness to work with a team ensure that all daily industrial operations run smoothly to increase efficiency and productivity constantly.

The best industrial operators tend to possess leadership qualities, excellent communication being one of them, to be able to coordinate different teams so that everything can run smoothly.

2. An industrial operator needs to be able to think on their feet

The ideal industrial operator needs to be a quick thinker. For example, if one of the industrial equipment starts acting up, the industrial operator should have the capability to develop a solution or alternative rapidly to prevent downtime on the factory floor.

An industrial operator should also be capable of resolving production schedule conflicts and coming up with even more efficient ways to produce and meet the required quotas.

3. They must have the know-how to handle different industrial equipment

The ideal industrial operator should be able to operate most of the equipment in the warehouse, from safety equipment such as light guards to large CNC machines found on the factory floor.

This wide capacity in machine knowledge essential in determining the most efficient and cost-effective way of acquiring the same end product.

Such knowledge can also come in handy, especially in a time of danger. Therefore, knowing safety protocols and procedures is quite important.

4. Industrial operators must be detail-oriented

Another important skill that an industrial operator should possess is the ability to pay close attention to detail and having a high concentration level.

In addition, being able to perform repetitive tasks every day for a long period without losing focus is necessary for optimal performance.

5. They need to be technically literate

As an industrial operator, you should be able to look at a schematic or blueprint and read it. This is an important skill, especially for an industrial operator as it is vital to their daily roles.

Technical literacy allows an industrial operator to make sense of different production processes, solve basic production problems, and increase the production line’s efficiency levels.

6. Be open and accountable

Everyone has weaknesses and strengths, and as an industrial operator, you should be able to know when to ask for help or when to consult with your superiors and juniors.

Also, when mistakes occur, industrial operators will take charge and look to resolve the situation as quickly as possible.

7. Be a teacher for others

One of the roles of an industrial operator is not just to honor the skills of the more experienced employees.

An ideal industrial operator should also be able to identify the less-experienced employees and help them nurture their skills and knowledge about industrial equipment operations.

8. Industrial operators should develop a sense of ownership of the industrial equipment

An ideal industrial operator will develop some sense of ownership of the industrial equipment to ensure that the equipment operates accordingly each day.

They should also be able to identify the capabilities and limitations of each machine in the industry. In short, the ideal industrial operator should care about the operation of industrial equipment and the productivity level as the manufacturer would.

9. Have great hand-eye coordination

Good hand-eye coordination is key to safety in a manufacturing setting. For example, industrial cranes have hydraulic joints to pinpoint the crane claw correctly. Without proper hand-eye coordination, one is more likely to damage equipment or even injure other employees.

10. Willingness to get their hands dirty

Finally, being open to messiness is the icing on the cake. Manufacturing lines can be dirty, greasy places, and industrial operators need to be ready to get into the mess if necessary.

As you can see, industrial operators are key employees in manufacturing with a variety of skills. These skills allow operators to carry out their jobs to their best ability.

FIND YOUR NEXT INDUSTRIAL OPERATOR WITH NRTC

Industrial operators are the heartbeat of any processing or manufacturing industry. Hiring the right industrial operator will ensure the smooth running of your industrial operations.

At NRTC Automation, we can help you find a top-quality industrial operator. So don't waste your precious time finding a needle in a haystack. Partner with NRTC Automation! We will train your current set of employees with the latest robotic and industrial equipment operation trends.

3 Steps to Transition into Industrial Automation

As industrial automation continues to revolutionize the manufacturing sector of the economy, what steps should you follow to automate your own company?

As industrial automation continues to revolutionize the manufacturing sector of the economy, what steps should you follow to automate your own company?

Industrial automation is a process of streamlining industrial systems by integrating smart tools and smart technologies to ease your production or fabrication process with very little human intervention. Automation reduces overall operating costs and the risk of human error through increased standardization, speed, and better adherence to the design specifications.

3 Steps to Transition into Industrial Automation

The key advantages of using industrial automation in your production line are an increase in efficiency, a reduction in human error and injury, minimal waste, and optimized lead time. NRTC Automation is making the entire process even easier with our automation services.

Where to begin with industrial automation

Sectors in need of automation to optimize the production process include manufacturing, processing, transportation, and warehousing.

There are three phases of automation, starting from the ground up:

BEGINNER PHASE

This is the first phase of automation. Starting with the basics helps companies understand the areas they can automate. Starting out with industrial automation includes these steps:

Identifying and evaluating areas for automation potential

Installation of sensing infrastructure (e.g. temperature, airflow, and pressure) and other simple task execution automation

Installation of single robots with basic programming to complete simple tasks

At this stage, most companies usually have limited infrastructure and resources for full industrial automation implementation. The general recommendation is to start automating smaller projects to test it properly.

And if it’s a success, it can be scaled further throughout the company.

INTERMEDIATE PHASE

Under this phase, a company is expected to have fully utilized its traditional automation processes so as to introduce some of the more complex automation processes. This phase involves:

Fully utilization of the basic sensing infrastructure installed in the previous phase so as to end up with a highly automated production process

Installation of more advanced sensing infrastructure such as vision systems

Installation of advanced programming that can take advantage of current optimization routines such as machine learning

Installation of industrial robot work cells to fully automate processes along the production line

This stage is where most small- to mid-sized companies find their comfort level and a balance between investment and productive output.

For larger corporations with heavily repetitive processes, such as automotive companies, the next stage of industrial automation may be better suited to their needs.

ADVANCED STAGE

This phase involves the introduction of more complex solutions such as Automated Mobile Robots and Automated Guided Vehicles (AGVs).

At this stage, most companies have mastered both traditional and cutting edge automation technologies that are crucial to industrial automation in all aspects of their operations by automating their manufacturing platforms, optimizing supply chains, and introducing complex data analytics to enhance their decision making.

This phase mainly involves:

Installation and utilization of advanced robotics such as automated guided vehicles

Utilization of the latest automation programming such as neural networks and artificial intelligence

Automation of the most significant indirect tasks such as engineering and management

Implementation of cybersecurity policies for industrial automation network

No matter what stage you’re at, industrial automation solutions can improve any aspect of your business and bring significant value.

Pillars of Industrial Automation

As Industry 4.0 introduces more automated systems along the production line to perform critical tasks, such as using programmable logic controllers (PLC) and automated infrastructure such as robots, Automated Mobile Robots, and Automated Guided Vehicles (AGVs).

The pillars of Industry 4.0 include:

Advanced data analytics

Data analytics is one of the largest contributors and drivers of industrial automation, which is based on the type of data you collect and how you process it. There are 4 types of data analytics.

Descriptive analytics: These analytics help you understand how effective your operations are, and what’s happening with your products and machinery, as it mainly relies on accurate and timely data that allows effective visualization of the company’s processes.

Diagnostic analytics: A diagnostic analysis is all about digging deeper into the root cause of a problem, by answering specific questions on why certain processes are less effective or why they have failed.

Predictive analytics: As the name suggests predictive analysis helps understand what’s likely to happen by reviewing and understanding certain patterns and tendencies. Predictive analytics do come in handy especially when forecasting demand and interpreting sales.

Perspective analytics: Perspective analytics is all about utilizing the information at hand and finding the best strategy to address a particular problem so that a business can optimize every process to its fullest potential.

Enterprise mobility

Enterprise mobility is the largest enabler of Industry automation as it combines several solutions such as enterprise mobility management, mobile app, and device management, together with client management. Some of the goals that intend to be achieved by these solutions include:

Data loss prevention

Compliance with security regulations

Bring your own device (BYOD) programs and other end-user accountability

Portability of the resources and adoption of the mobile applications.

Industrial Internet of Things (IoT)

Technology is key when it comes to automating field operations and integrating with business processes. It allows manufacturers to closely monitor the health and performance of their devices, perform remote troubleshooting, scheduled maintenance, and ensure the safety of operations for employees.

Types of IoT implementations for industrial manufacturing include:

Supervisory Control and Data Acquisition (SCADA) collects real-time data and processes it in real-time through direct integration with sensors, so as to provide insights for optimization.

Programmable logic controllers (PLC) are computers programmed for automatic operations using information from sensors.

Computer Vision

As more companies continue to adopt machine learning and AI, computer vision is providing better solutions to these companies by providing machines with the ability to open doors to new business opportunities on behalf of these companies.

For example, a vision guided robot can identify and analyze a company’s position in regard to the production of a certain item and react as programmed.

Artificial Intelligence and Machine Learning

27% of the largest companies globally have adopted some form of artificial intelligence and machine learning into their processes.

But as small- and mid-sized companies start to catch up with industry leaders through the adoption of advanced machine learning algorithms, these companies are reducing their manual work, optimizing costs, and enabling intelligent decision making.

HARNESS THE POWER OF AUTOMATION WITH NRTC

NRTC Automation is an industry leader when it comes to industrial automation. With NRTC Automation, you can increase your company’s throughput and also maximize profitability.

Unlock your digital factory with NRTC, with automated data collection and product analysis to deliver data-driven insights.

Take action with NRTC Automation and improve your company’s bottom line.

5 Types of Industrial Robots

Learning more about industrial robots will help make automation easier for any manufacturer.

Learning more about industrial robots will help make automation easier for any manufacturer.

It’s estimated that nearly 45% of production can be automated with robots.

There’s a variety of industrial robots available to suit nearly every need. In order to choose which type of robot is best, it’s paramount to start from the paradigm of “form follows function”. In other words, the choice of robot form factor should be dependent on its purpose.

Because there’s a wide variety of tasks that can be accomplished with industrial robots, consequently, there’s a number of robot varieties available that are suited to different types of tasks.

Learn more about the advantages of each type of industrial robot below!

What is an industrial robot?

A widely accepted definition for an industrial robot by ISO 8373:2012 is “an automatically controlled, reprogrammable, multipurpose manipulator, programmable in three or more axes, which can either be fixed or mobile for use in industrial automation applications.”

Though industrial robots are available in various form factors depending on the task, the most common industrial robots are automated arms. These robots can be classified into a few different categories based on movement, application, architecture, and brand.

Types of industrial robots

The most common type of industrial robot is a stationary robot--meaning robots that are bolted to a surface such as a floor, ceiling, or walls. There are five main types of stationary robots (or “robotic arms”) available today that can accomplish tasks such as sorting, welding, and finishing. According to the International Federations of Robots, the five main types of industrial robots includes SCARA, Articulated, Cartesian, Delta, and Polar.

ARTICULATED ROBOT

Advantages: Joints allow flexibility of movement. As a result, a broad range of tasks may be performed.

Disadvantages: Articulated robots are more costly compared with other robot arms, and require more sophisticated control systems.

The most common industrial robot structure is the articulated arm, which accounts for 60% of installations worldwide, according to the International Federation of Robots. These robots resemble a human arm and have structures analogous to a shoulder, elbow, and wrist.

Articulated robots have between two to 10 joints which allows them a flexible range of motion to accomplish dynamic tasks. As the number of joints increases, the more “smooth” the robot’s motions become.

Typically, articulated arms can pivot six degrees of freedom. Although this is less than that of the human arm which can rotate seven degrees of freedom, the range of motion is sufficient for almost any task.

The robotic arm may be attached to a gripper, which is analogous to a hand. The gripper may be as simple as suction cups or as complex as hand-like structures with fingers that can grip and pick up objects.

Similar to robot type, the type of gripper is dependent on the task. Alternatively, grippers may be drill bits, sanders, lasers, and almost any type of specialized tool.

Because of their flexible range of motion allowed by joints, articulated robots have many applications. They are used most often for printing, packaging, welding, machine tending, material handling, and metalwork.

SCARA ROBOTS

Advantages: Cost-effective, accurate, and proficient in a variety of assembly approaches.

Disadvantages: Limited range of motion and less efficient than Delta robots

SCARA is an acronym for Selective Compliance Articulated Robot Arm and describes robots with two parallel rotary joints. While SCARA robots are faster than Cartesian robots, they are less precise. Though they are able to move along all three axes, these robots specialize in lateral movements.

SCARA robots revolutionized small electronic manufacturing because of their small footprint, simplicity, and low cost. They are particularly well-suited for assembly applications. The “C” in SCARA stands for “compliance” and refers to the small amount of “give” in its horizontal plane. However, SCARA robots are rigid in their vertical plane, hence the naming structure of “selective compliance”.

SCARA robot’s selective compliance is helpful for inserting parts into single-planes like circuit boards. Fitting a part into a hole requires some rigidity that is not possible with other types of robotic arms. However, SCARA robots have lower weight limits and fewer degrees of freedom due to this design.

CARTESIAN (RECTANGULAR) ROBOTS

Advantages: Can be more cost-effective and have simpler controls, with greater accuracy.

Disadvantages: Can only move linearly in three dimensions.

Cartesian robots operate on three linear axes (forwards and backward, up and down, and side to side). They get their namesake because they operate on the Cartesian Coordinate system (X,Y, and Z). In other words, they move horizontally and vertically in each ninety-degree plane.

Cartesian robots are frequently utilized for material handling, 3D printing, packaging, drilling, and storage or retrieval. Because Cartesian robots only operate linearly in three dimensions, their actions are more accurate. Additionally, they are more cost-effective and have simpler controls.

Advantages: Quick and accurate motions.

Disadvantages: Weight and range of motion restrictions.

Delta robots are popular in the manufacturing of food, pharmaceuticals, and electronics. Delta robots are frequently described as “spider-like” because they are crafted from jointed parallelograms connected to a base and are typically mounted above a workspace.

The Delta robot has sweet origins--it was originally created to pick up pieces of chocolate and place them in a box. Because of its light design, its motions are accurate and very fast.

POLAR (SPHERICAL) ROBOTS

Advantages: Simple control systems, long reach, and fast operations.

Disadvantages: Less flexibility compared with articulated arms and require larger footprints.

Polar robots, also known as ‘spherical robots’, possess an arm attached to two rotary joints and one linear joint. These robots move along polar coordinates, which allows a spherical range of motion.

The first industrial robot ever created was a spherical robot named “Unimate”. Unimate worked on General Motors assembly lines beginning in the 1950s, transporting die castings and welding parts onto auto bodies.

While still in circulation, polar robots are considered slightly obsolete technology that can be replaced by more versatile articulated robot arms. However, polar robots can still be more cost-effective.

When deciding on which type of robot to select, it’s most important to decide on the task or set of tasks it’s required to perform. Additionally, prospective robot owners will need to think about interoperability with existing infrastructure. With a range of options on the market, manufacturers can weigh the costs and benefits to decide on the best model for their needs.

AUTOMATE WITH NRTC

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Contact us today to learn more about how we can help you meet your production goals.

Global Industrial Robotics: Growing and Emerging Markets

NRTC Automation reports on the current state of automation around the world.

NRTC Automation reports on the current state of automation around the world.

The International Foundation of Robots (IFR) predicts there will be nearly 4 million robots worldwide by 2022. Despite short-term declines in industrial robot adoption as a result of COVID-19, the global average robot density achieved a new record of 113 robots per 10,000 employees.

While the global outlook is promising, automation maturity is very variable from country to country.

Global Industrial Robot Market

INDIA: 4 ROBOTS PER 10,000 EMPLOYEES

Although India severely lags behind global robot density, the country is one of the fastest-growing among emerging Asian markets.

Traditionally, the strongest driver of robot installation is the automotive industry, which accounted for 44% of installations in 2018. However, the general industry, which consists of the rubber and plastics, metal, and electrical / electronics industry, has recently overtaken automotive.

The gap in robotics automation in India is commonly attributed to:

Absence of adequate hardware ecosystems: Robots require high-end components, the majority of which need to be imported into India.

Robot expense: On top of the high cost of industrial robots, import tariffs and taxes are 28.85% in India. In comparison to the low average annual wages for workers, robotics can be prohibitively expensive.

Deficit of expertise: Robotics requires specialized skills and education, which is lacking in the country.

Late to market: India entered the robotics race late, compared to other nations. Therefore, India’s robotics industry is still catching up.

MEXICO: 33 ROBOTS PER 10,000 EMPLOYEES

While Mexico lags behind the global average at 33 industrial robots per 10,000 workers, it displays modest growth. The country is expected to hit nine thousand industrial robotics sales in 2021.

Automation is most prevalent in Mexico’s automotive and auto parts sectors, trailed by semiconductors and electronics.

Mexico is one of the world’s largest economies and includes a variety of manufacturers. Since many U.S. manufacturers have moved their operations to Mexico, the country has even more motivation to further automate.

UK: 85 ROBOTS PER 10,000 EMPLOYEES

The UK lags behind major global and European competitors in its industrial robotics usage. Industrial robots in the UK are most heavily embedded in the food and beverage and automotive industry while demand is trending in manual industries such as construction.

Many experts attribute some of the UK’s stagnation in productivity (measured by GDP per hours worked) since 2008 to its slow industrial robotics adoption. When compared to nations with similar manufacturing output, the UK utilizes fewer industrial robots, and productivity suffers.

Despite lagging in adoption, industrial robotics has experienced a rise in demand. After a short decline following the COVID-19 outbreak, sales of industrial robotics in the UK increased by 52% in Q4 of 2020.

The government recognizes the importance of automation and intends to invest more of its GDP into R&D to catch up to other superpowers.

CANADA: 165 ROBOTS PER 10,000 EMPLOYEES

Canada ranks 18th in the world for robot density and is significantly above the global average in robot density (165).

Robots are primarily used in the automotive industry, where density is high. However, when the automotive sector is removed, Canada’s robot density is merely 71 and lags considerably behind other superpowers such as the U.S. The UK’s robot density is well below the global average, with only 85 robots per 10,000 employees. At that density, you’d only expect to see robots in plants employing more than 140 people.

Canada’s adoption rate is another cause for concern. Average robot density increased by just 20 units (compared to 39 in the U.S.). Although the cost of integration and lack of flexibility are significant barriers to adoption, the country is hopeful that advances in innovation will reduce blockers.

CHINA: 187 ROBOTS PER 10,000 EMPLOYEES

China is still developing robot density and currently ranks 15th in manufacturing robot density worldwide. However, China outpaces the global marketplace in its continued adoption of automation.

Industrial robotics is most prevalent in the Chinese car industry (which has been the largest in the world since 2013). It’s estimated that the industry uses a whopping 500 robots per 10,000 workers. Robotics use is also scaling in electronics and logistics, which average around 50 robots per 10,000 workers.

China’s robotics industry experience rapid growth throughout 2020 and 2021. According to the IFR “It is the fastest-growing market worldwide. There has never been such a dynamic rise in such a short period of time in any other market.” The country now accounts for 45% of all global industrial robot shipments.

While the country boasts a large workforce, the cost of labor continues to increase at a higher rate than other manufacturing countries like Vietnam. Therefore, China is incentivized to automate manufacturing to improve output and quality.

China’s long-term strategy is to support robotics startups in key industries and expand industrial robot use from traditional caged robots to robots that work collaboratively with humans.

JAPAN: 364 ROBOTS PER 10,000 EMPLOYEES

Within the last few years, Japan outpaced Germany in robot density. Despite ranking in third place in robot density, Japan undoubtedly leads the world in robot manufacturing. In fact, Seven of the 10 world’s principal industrial robotics companies are headquartered in Japan.

In Japan, even robots are assembled by robots. According to the IFR, the country’s output represents 47 percent of total global robot production.

Industrial robots are most prevalent in the electrical and electronics industry (34% share of operational stock), the automotive industry (32% share of operational stock), and the metal and machinery industry (13% share of operational stock).

Japan is also known for spearheading innovation in robotics technology. The country drives development and testing in emerging technology, such as machine vision, machine learning, and artificial intelligence.

Due to this reputation, the country is considered ground zero for new robotics applications. Enterprise companies like Mitsubishi, Kawasaki, and Denso along with the government drive the continued development of industrial robotics in the country.

According to the International Trade Administration, Japan’s industrial machinery market is expected to continue to experience a growth phase. By 2065, the government is planning for a 40 percent reduction in its total workforce because of its aging population. Industrial robotics is expected to help alleviate the gap.

Start automating today

Advancements in robotics technology, emerging demand for high-quality and sophisticated products, and increasing remote and dangerous working environments will drive automation. Countries with mature or rapidly growing automation strategies will continue to thrive, while many other may be left behind.

WORK WITH NRTC AUTOMATION