NRTC AUTOMATION BLOG | INDUSTRIAL ROBOTS AND AUTOMATION

4 Reasons a Turnkey Work Cell Will Improve Your Production

Turnkey weld cells are an easy way to implement efficiency and productivity in manufacturing and production. Adding turnkey weld cells can keep companies on the cutting edge and reduce waste.

Turnkey weld cells are an easy way to implement efficiency and productivity in manufacturing and production. Adding turnkey weld cells can keep companies on the cutting edge and reduce waste.

Cells can be either pre-manufactured or customized for the specific needs of a company or production line. NRTC Automation can design, engineer, and build a turnkey weld cell to fit all of your production needs.

Read on to find out four reasons a turnkey work cell will improve your company’s production and why you should add one to your manufacturing set up.

INCREASE PRODUCTION

One of the most enticing factors of a turnkey weld cell is its ability to increase production rates, without sacrificing quality. Adding work cells creates less of a margin of error than using manual labor, and has higher repeatability compared to in-house human workers.

Many companies are also implementing turnkey weld cells with cobots, collaborative robots that work safely and seamlessly with humans, and have a lower price point.

There are also companies that are installing turnkey weld cells into their fully automated facilities, streamlining the entire warehouse. These so-called dark warehouses are able to operate 24/7 and increase production through automation and AI.

SAVE MONEY

Implementing turnkey work cells is a cost-efficient method of production. Not only can turnkey weld cells replace expensive labor costs, but installing automation with work cells often solves the problem of staffing when there are shortages.

A work cell is less expensive than buying new equipment individually and adding a custom turnkey weld cell to your facility can save you money in the long haul by increasing efficiency and production run time.

Utilizing a turnkey work cell also minimizes downtime when manufacturing, which can cost an average of $260,000 per hour. The average downtime of production is roughly four hours, which can end up with an average cost of $2 million.

A robotic weld cell reduces that downtime with a constant workflow. Having, for example, a work cell with automatic tool changers allows robots to quickly change applications, and speed up delays.

Additionally, robots don’t require light or air conditioning, so manufacturers are able to save even more money by cutting costs for heating, cooling, and lighting.

HIGHER QUALITY PRODUCT

Implementing a turnkey weld cell increases the quality of your product, due to its high repeatability and precision. Self-contained in one cell, automation production assembles, welds, dispenses, and more. Choosing a well-planned robotic work cell, or using a custom design to fit your needs, can overall enhance your product quality.

Choosing a partner like NRTC Automation ensures that you are being delivered high-quality services that will not only improve your manufacturing processes, but increase your revenue and cut production waste.

A TOTAL SOLUTION

A turnkey weld cell is an all-in-one solution to all your automation needs. Pick and choose the robots and their functions to fit your manufacturing needs. NRTC offers pre-engineered and customized work cells that are the ultimate turnkey solution.

For companies of all sizes, a turnkey work cell is an easy and affordable way to effortlessly automate your company.

NRTC is the Source for Automation Solutions

We at NRTC Automation are dedicated to providing industrial automation and manufacturing solutions. Along with decommissioning and industrial robotic training services, NRTC is the key to integrating and streamlining your production facility.

Contact NRTC Automation today to find out all the ways we can help you automate.

Key Components to Increase Your Production Line’s Efficiency

A key to a successful manufacturer’s production line is efficiency. Ensuring an efficient production line guarantees higher returns, less waste, and a high standard of production quality. Taking steps to ensure that your production line stays efficient is an important part of the manufacturing process.

A key to a successful manufacturer’s production line is efficiency. Ensuring an efficient production line guarantees higher returns, less waste, and a high standard of production quality. Taking steps to ensure that your production line stays efficient is an important part of the manufacturing process.

Keep reading to learn what steps you can implement to keep inefficiency at bay and your production line running smoothly and performing at its highest caliber.

Automation

Automating a production line is one of the easiest steps you can take to improve the efficiency of your production line. Implementing industrial robots and solutions like turnkey weld cells allow your production line to seamlessly blend with your workers, producing a higher-functioning production process.

Automation keeps your company in line with current competition and allows businesses to grow in scale and capacity with ease. Investing in automation can unlock efficiencies, and also keep businesses competitive with lower labor cost markets overseas. Without this, manufacturing business can and do shift from the US to an overseas market.

Maintenance of Robots and Equipment

A production line is only as good as its machines, so it’s vitally important to keep robots and production equipment well maintained. Not only should a daily, weekly, and monthly maintenance and tune-up be kept, but additional reconditioning and refurbishment should be considered should a production line show signs of slowing down or using more energy than usual.

Reconditioning or refurbishing can extend the life of your robot and breathe new life into the machinery. During a refurbishment, robots are cleaned, broken parts are repaired, and testing is done to ensure that the machine is running top of its game.

Refurbishment can even go as far as returning a robot back and restoring it to factory new settings, along with a bright new paint job to match the squeaky clean like-new interior.

Training

Keeping your employees trained and at the top of their game is just as important as maintaining machinery and industrial robots. Employees are the heart of the company, and not only do they maintain automation production day-to-day but they will often be the first point of contact when a problem arises.

Continual training on new safety measures, production hardware and software updates, and the latest OSHA safety measures ensure efficiency in the workplace. Keeping robots operating smoothly and the floor safe limits downtimes on both a machine and worker front.

Product Quality

Did you know poor quality materials can slow your production line? Not only do low quality materials often create more waste, but they can create waste through products that don’t meet a high-quality standard.

With supply chain issues often being a source of frustration, especially in a post-Covid world, it’s important to find a reliable supplier, and stick with them, even if there might be a few delays. Ensuring that your product is of the highest quality keeps customer’s happier, and your companies reputation in good standing.

NRTC Automation

NRTC Automation is trusted by companies worldwide to provide comprehensive industrial automation and manufacturing services. We’ve worked with top manufacturers for more than a decade, supplying them with engineering contract services, turnkey weld cells, industrial robot refurbishment, and more.

Contact us today and schedule your free consultation, and learn more about all the services that we offer.

Streamlining Your Manufacturing - 4 Ways to Overcome Problems

The manufacturing industry comes with its own set of problems and challenges. Waste tends to be the biggest problem in the industry, and comes in multiple forms, from product and time, to energy and money.

There are ways to improve and work towards a lean manufacturing standard with sustainable productivity. Read on to learn four ways to overcome common problems that the manufacturing industry encounters.

The manufacturing industry comes with its own set of problems and challenges. Waste tends to be the biggest problem in the industry, and comes in multiple forms, from product and time, to energy and money.

There are ways to improve and work towards a lean manufacturing standard with sustainable productivity. Read on to learn four ways to overcome common problems that the manufacturing industry encounters.

Automation

Automating production is the easiest way to overcome many of the challenges that the manufacturing industry has. Many manufacturing companies that are currently integrating automation to their production are not only using it to streamline in the present, but to plan for expansion and future automation.

Adding turnkey weld cells and industrial robots can save not only time, but costs. Labor costs for the US could shrink dramatically by 2025 with the addition of robots. NRTC customers alone have seen a 200 percent increase in throughput from implementing our turnkey weld cell solutions to their production processes.

Using the latest technologies such as automation not only keeps a company’s production operating smoothly, but makes them more competitive in the market compared to similar companies. Saving time and money allows for products to stay at a better price point for both a consumer and a manufacturer.

Training

Training employees is a simple and effective way to overcome issues that might arise on a production floor. Thoroughly trained employees will be able to spot issues quickly, as well as ensure consistent maintenance plans for the facility and machinery.

Training for employees also involves making sure all proper safety measures are being implemented Almost all safety related accidents can be prevented with proper training, preventing not only a loss of money, but a potential loss of time and employees. In fact, the aggregate cost of work injuries to the U.S. economy in 2019 was $171 billion.

NRTC Automation offers training programs for a variety of tasks, from familiarizing your team with the latest in robotics to offering hands-on training in programming and troubleshooting.

Analyze Data

Automating production allows for manufacturers to look deeper into the data collected during production. Reading the results of production allows for weaknesses to be detected early, increases or decreases in production monitored, and adjustments be altered as needed on the fly.

Taking a data-centric approach with data-forward software can more precisely measure success, and create a system of records so all employees and team members work with the same data. This creates clarity and clear communication across all channels.

Regular Maintenance

Regular maintenance should be a part of all manufacturing and production protocols. Along with daily, weekly, and monthly checks on robots and machines, reconditioning should be considered an important element in the maintenance cycle. Reconditing your equipment by cleaning out dust, removing old grease, replacing old parts, and regreasing joints. This will extend the life of equipment and ensure many years of use.

NRTC offers industrial robot refurbishing to extend the lives of your robots and return their functionality to the highest caliber. From basic testing to complete overhaul, NRTC has a refurbishment solution to fit your needs. Additionally, we can help with restoring your robot to its visual best with our repainting services, as well as assisting with industrial robot repairs.

NRTC has Automation Solutions

NRTC Automation is dedicated to assisting with industrial automation solutions, from turnkey weld cells to robot repair and maintenance. Our additional assistance through options like engineering contract services and parts manufacturing. Learn more on our website, or contact us for more information.

Why should you Outsource Parts Manufacturing?

As manufacturing moves back into the United States, moving production in-house has been on the minds of many businesses. While moving production in-house does have its benefits, there are many reasons to continue to outsource parts manufacturing.

Signs Your Robot Needs Repair

Production lines rely on industrial robots to keep manufacturing on track and running smoothly. A breakdown or malfunction can put a wrench in production, and cause downtime and a loss of profits. Knowing the signs that your robot needs repair can keep things running smoothly and downtime at a minimum.

Production lines rely on industrial robots to keep manufacturing on track and running smoothly. A breakdown or malfunction can put a wrench in production, and cause downtime and a loss of profits.

Knowing the signs that your robot needs repair can keep things running smoothly and downtime at a minimum.

Read on to learn what signs to look for that might indicate your robot needs repair.

WASTING TIME AND ENERGY

Industrial robots are designed to make a production line more efficient, so if you notice that it might not be performing up to standard, this is a clear indicator that repair or maintenance may be needed. Watch for the robot’s movements and if there seems to be a delay, or if there are unnecessary gestures or motions, diagnosing issues and repairs should be on the docket.

NRTC Automation runs robots through at least 50 cycles so that we can observe movements, motions, and its ability to repeat each function. Observing this way allows for surface-level errors to be easily spotted, and we can create a checklist to problem shoot based on what errors arise.

INSPECT THE TEACH PENDANT

Teach pendants can offer one of the most straightforward indicators of an issue. A teach pendant, or teach box, is the control box for a robot’s programming. They are used to teach a robot the step-by-step processes that it will be required to perform and is usually handheld. Think of it as an educational gaming system.

If you think there might be an issue with your robot, consult the teach pendant and programming as one of the first steps in troubleshooting. There is valuable information in the system, and if there are any programming errors, they should show up on the pendant’s screen.

CHECK THE CHARGE

An easy checklist item when troubleshooting robot issues should be checking the batteries. Something as simple as a low or depleted battery can cause a variety of issues.

Keeping a robot’s batteries updated should be a part of routine maintenance, and logging install and replacement dates a part of normal documentation.

OVERHEATING

Robots and machinery, when running, produce heat, and there are standard temperatures to look for in motors and elements, such as the servo motor. If these are overheating, that can be a sure sign that your robot needs repairs.

ADDITIONAL TROUBLESHOOTING

Additional signs of repair to look for include the inability to upgrade properly, a lower than usual number of completed cycles, or connection errors. And when it comes down to it, no one knows your robots better than the people that work on them every day. If you or your employees think there might be a problem, it’s worth looking into it.

Prevention is Key

Routine maintenance, planning, and installing timely updates are all key to keeping a robot working at peak performance. NRTC Automation offers not only training but industrial robot refurbishing.

Reconditioning and refurbishing ensure your robot stays running smoothly and efficiently. Additionally, investing in maintenance and refurbishment is cheaper than replacing it with brand new equipment.

NRTC Automation robotic training programs work with your team to personalize hands-on training based on your needs and requirements. The end result is an empowered team with the confidence and skills to diagnose and repair robots in-house.

Designing Your Weld Cell - 3 Things You Need to Know

Robotic weld cells can help production lines increase productivity and efficiency, as well as keeping costs lower. While individual industrial robots can be great, weld cells are pre-engineered to run production according to a job specific need.

In a constantly evolving competitive economy, adding elements like robotic weld cells keep companies on the cutting edge and able to focus on efficiency. And with many production cells cutting down on waste, there is not only higher profit, but an increasingly better relationship with the environment.

There are important steps and processes to consider as you are designing a weld cell for a production line.

Continue reading to learn three things you need to know before designing your weld cell.

MAKE A PLAN

It seems like a simple and straightforward idea, but knowing exactly what your work cell needs to do is an important first step when designing. Asking questions like, “What will my work cell be producing?” is key to knowing exactly what parts to include in the cell, and how to program it.

Each work cell that is in existence has not only specialized parts, but unique programming to both the task and machine. Being as specific as possible in this early stage helps streamline building and programming, and ensures less down time as you start to design.

Part of making a plan should be developing an outline, including mapping out tasks before production and building begins. A solid outline will act as a framework for production, and make sure all steps of the automation process will be included.

PICK YOUR PLAYERS

Once a thorough plan is created with an outline, it’s time to select the industrial robots and parts for your weld cell. As you are searching for robots, there are a few important points that should be considered:

Robots' Reachability – This can determine the number of robots and spacing.

Payload Limitations – Consider what you are producing, and the weight and size limitations of the equipment you are selecting.

Precision Capabilities – Determining what you will be producing and the finer nuisances that might be needed can separate one robot choice from another.

End of Arm Tooling (EOAT) - Knowing what equipment you will need on the end of your robotic arm can help to narrow down purchasing options.

Cycle of Time – The speed of the robot is a good indicator for a production line’s efficiency and speed.

In considering what robots to select, a positioner also needs to be chosen. The positioner is what will hold or contain your product that is being manufactured. It can be mobile or fixed, with factors such as adjustable height and weight capacity being taken into consideration when selecting an option.

LAY IT ALL OUT

Once you’ve developed an outline, and selected your production equipment, it’s time to create a layout. This is the most important aspect of design, as you are figuring out the placement of both robots and positioners to achieve maximum efficiency.

Consider how your work cell will be laid out. Will it be in a linear fashion, or will it have turns, or changes in direction?

As you lay it out, make sure to think about not only how it will fit into a manufacturing facility, but how staff and employees will be positioned in the workflow. Safety is always the most important factor, and protecting and making sure employees are comfortable should be a top priority.

NRTC Automation Solutions

NRTC specializes in custom turnkey weld cells for manufacturers of all sizes. From startups to top automotive OEMs, all of our work cells are refurbished, ensuring turnkey automation that is ready-to-work and affordable.

For more information on our automation solutions, turnkey weld cells, and parts manufacturing, contact us or visit our website for more information.

3 Ways to Improve Efficiency in your Production Line

Production lines are installed in industrial manufacturing to increase production and efficiency. But what happens when those lines begin to slow, waste money, energy and ultimately affect a company’s bottom line?

Production lines are installed in industrial manufacturing to increase production and efficiency. But what happens when those lines begin to slow, waste money, energy and ultimately affect a company’s bottom line?

It’s important to be aware of signs a production line is being inefficient, and how to improve performance.

Read on to learn more about ways to improve efficiency in your own production line.

RECONDITION YOUR EQUIPMENT

Production lines rely on manufacturing equipment and industrial robots to be in prime condition in order to keep processes as efficient as possible. Over time, even new machines purchased will begin to show wear and tear, and it’s important to know the signs to spot when it’s time to give your equipment new life.

Routine maintenance is key to staying on top of repairs or cleaning that might need to happen in order to keep your industrial robot or machine running like new. Finding a balance between regular updates and downtime is important when evaluating the maintenance schedule. If more repairs and upkeep are required over time, it may be an opportunity for reconditioning your equipment. Reconditioning extends the life of machinery and can involve something as simple as a deep clean, removing dust, grease, and other items, or replacing old parts.

NRTC Automation offers two levels of reconditioning services, which are tailored to your individual requirements, as well as offering industrial robot painting services and repairs.

EMPLOYEE TRAINING

Although manufacturing automation depends largely on robotics and machinery, the employees of a business, especially a production facility, are just as, if not more, important than the production line itself.

Employees need to stay engaged and informed, with regular meetings and cross-training. A regular meeting schedule with staff can not only keep employees abreast of any future changes or updates, but also keeps a line of communication open for employees to express problems on the floor or with current machinery or industrial robots.

Additional training, such as cross-training, allows for a wider net of safety and information to be cast over a production facility. If an employee can understand the entire production process, they are then able to assist others in different roles if needed or to fill production gaps.

NRTC provides robotic training services for industrial manufacturers and production facilities, allowing for employees to keep up-to-date on new information, technology, and processes.

UPGRADING SYSTEMS

If an industrial robot is passed the point of being able to be reconditioned, it is worth it to look into replacing the machinery. Often times, replacing a system can be more cost-effective in the long run than continually repairing and reconditioning it.

Purchasing a newer, but still used, high-quality machine or robot is a price-saving practice that can still upgrade production without breaking a budget. Our sister company iGAM has multiple options for high-end used industrial machines and robots.

Additionally, implementing lean manufacturing processes that create less waste can improve production efficiency, save costs, and of course, positively impact the environment. NRTC Automation specialized in designing, engineering and building custom, turnkey robotic work cells that can increase productivity and efficiency in your production line.

NRTC CAN HELP

NRTC Automation helps manufacturers of all sizes with automation, training, and robotic solutions to fit every need and keep production efficient. We offer custom turnkey weld cells, engineering contract services, and more. To learn additional information, or to contact our team, visit us here.

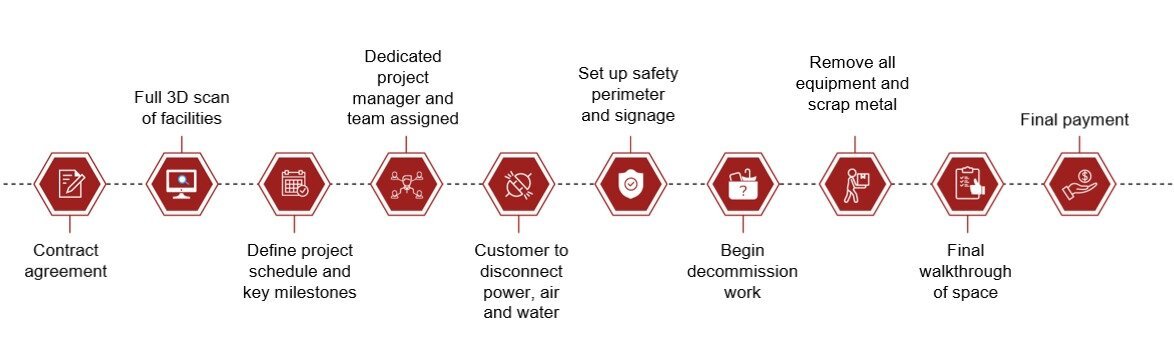

Decommissioning – How Does it Work?

Decommissioning can be a mystery process. Seemingly overnight, a facility or space containing industrial machinery can be emptied, cleaned, and ready to be repurposed. But what is the process behind it?

Decommissioning can be a mystery process. Seemingly overnight, a facility or space containing industrial machinery can be emptied, cleaned, and ready to be repurposed. But what is the process behind it?

NRTC Automation is at the forefront of decommissioning services, and we support and walk customers through the process every step of the way. Read on to learn more about how our decommissioning process works.

How does decommissioning work?

FIRST, DETERMINE IF IT’S TIME TO DECOMMISSION

The first step in the decommissioning process is to determine that the industrial machine or space is ready to be decommissioned.

For an industrial machine or robot, are you replacing parts often, or are spare parts becoming a challenge to find? How much money do you have to invest in repairs and maintenance? Answering these questions can help you determine if it is time for decommission or replacement.

Perhaps a company has outgrown its warehouse and needs to move to a larger space, or adversely has decided to close its doors. These instances would require decommissioning on a bigger scale.

NRTC can decommission anything from individual robots to facilities larger than 750,000 square feet.

PREPARATION NEEDS TO BE COMPLETED

Once you have decided to decommission, it’s time to make sure all the prep steps are completed. Obtaining approvals from the board and management are important, as well as figuring out if the space or facility will be reused or demolished.

It’s also important to set and define time restrictions the project might have, such as moving dates or target goals for the repurposing of the facility.

If there are any assets that are going to be moved to another facility, such as an industrial robot or machine, it’s important to transfer those ahead of time. All other assets marked for decommissioning will be taken care of during the process.

Once the prep work is complete, it’s time for NRTC Automation to take over.

LET THE DECOMMISSIONING BEGIN

NRTC starts the decommission process with a 3D facility scan, which includes photos of all industrial equipment and a layout of the facility. Then, a project manager oversees the tear out, from start to finish.

As part of the process, we identify the equipment of value versus those machines that will need to be scraped, and remove one section at a time, making sure we consult on the method of removal that fits best for a business.

As NRTC moves through the process, the project manager will provide updates of the project through key milestones and the timeline developed, and communicate a schedule of all the steps. Transparency throughout allows for constant updates, and keeps the project on track.

Safety is our priority, so expect safety signage and other measures in zones that could be potentially hazardous or dangerous. The NRTC team will wear branded safety gear for visibility and we take all precautions listed by OSHA.

TIE UP LOOSE ENDS

Once NRTC Automation has completed the tear out, we complete the broom-ready space by cleaning up any loose ends. This includes making sure the floor is smooth and removing any wires, hooks, or bolts that may keep the floor from being flush.

Once finished, you have a space that is ready to be swept and repurposed, and the project manager will do one last walkthrough to ensure all steps are completed.

DECOMMISSIONING WITH NRTC

Decommissioning doesn’t have to be a mystery, or a long, -drawn-out process. NRTC Automation’s comprehensive decommissioning services place an emphasis on safety, speed, and efficiency. We have a customizable yet structured industrial tear-out service, and work with companies to meet deadlines, develop a plan, and make sure a broom-ready facility is complete at the end of the process.

Contact NRTC today to learn more about our quick and painless decommissioning services, and how we can help you.

NRTC: How Do You Know When It's Time to Decommission?

Not everyone finds it easy to decommission old equipment, mainly due to a lack of proper guidance on letting go of industrial machinery.

Not everyone finds it easy to decommission old equipment, mainly due to a lack of proper guidance on letting go of industrial machinery.

It can be difficult to determine when you should decommission your equipment. You may not be sure of what signs to look for, or if the money you are putting into it outweighs the investment.

Eventually, your machine is going to wear out, and when it does, you have a choice to make. Deciding it is time to say goodbye, and decommission it, or invest more money in repair costs.

Signs that confirm you should decommission

#1: ABNORMALLY HIGH REPAIR COSTS

Even a machine that gets regular maintenance will one day encounter a large repair issue, and with that, a high cost. Knowing when that cost, paired with the regular maintenance, is becoming too much is key to knowing when to decommission.

Mechanics and machinery do wear over time, and replacing parts is required over the years. When this starts to happen with more frequency, take time to examine the cost you are putting in for upkeep versus the cost for a replacement.

Purchasing a used machine can keep costs low and solve ongoing repair issues. Our partner, HGR, carries a wide selection of industrial surplus including used machines and robots, and they are a great resource when looking to replace your decommissioned machine.

#2: THE MACHINE BECOMES A SAFETY CONCERN

The safety of employees and staff should always be the number one priority of a workplace. If a machine becomes a health or safety hazard, decommissioning should be done immediately.

Safety hazards may not be as visible as a worn belt or sparks. If a machine doesn’t start up the way it should, the cause should be investigated promptly, as it could be an indication of something potentially hazardous. Make sure your staff is communicating any issues with machinery that could lead to a safety hazard, and ultimately, decommission.

#3: EQUIPMENT DEPRECIATION

Equipment depreciation happens naturally over time, even with regular maintenance and care. Unless the machine sits idle at an industrial warehouse, each time it runs it will reduce its value.

As depreciation happens, make sure you do some quick financial calculations. Choices can be made to run the machine until it surpasses its usefulness, or sell it prior to the end of its lifetime, and make a return on your investment. A clear financial picture can help you to make an objective decision regarding decommissioning.

#4: COST OF MACHINERY INSURANCE INCREASES

Insurance is a necessary part of machine ownership, but can also be a great indicator of when it may be time to decommission. When your premiums start to increase, it means the insurance company has evaluated the risk of that machine as increasing due to age.

Insurance companies will also lower premiums based on new safety measures. If you do have to decommission, look for a newer used machine or robot that may save you on insurance as well.

NRTC IS YOUR GO-TO PARTNER FOR ALL DECOMMISSIONING NEEDS

It is time to say goodbye to your equipment when it no longer functions as it should despite all the many repairs and maintenance. At NRTC, we are the experts in decommissioning machinery We have transparent processes that give you visibility from start to finish.

The Lifecycle of Working with NRTC

NRTC Automation will help you get started on the important automation journey to improve production throughput and minimize downtime.

NRTC Automation will help you get started on the important automation journey to improve production throughput and minimize downtime.

Automation is directly associated with an increase in productivity, efficient utilization of resources, improved safety, enhanced product quality, and reduced labor.

Increased productivity and higher output are the biggest factors that justify our push for industrial automation. Additionally, automated systems deliver consistency during the manufacturing process. That leads to greater control of product quality.

NRTC is your ideal automation partner. Our wide range of services can help you make the most of what automation offers.

Keep reading to find out more about the lifecycle of working with NRTC Automation.

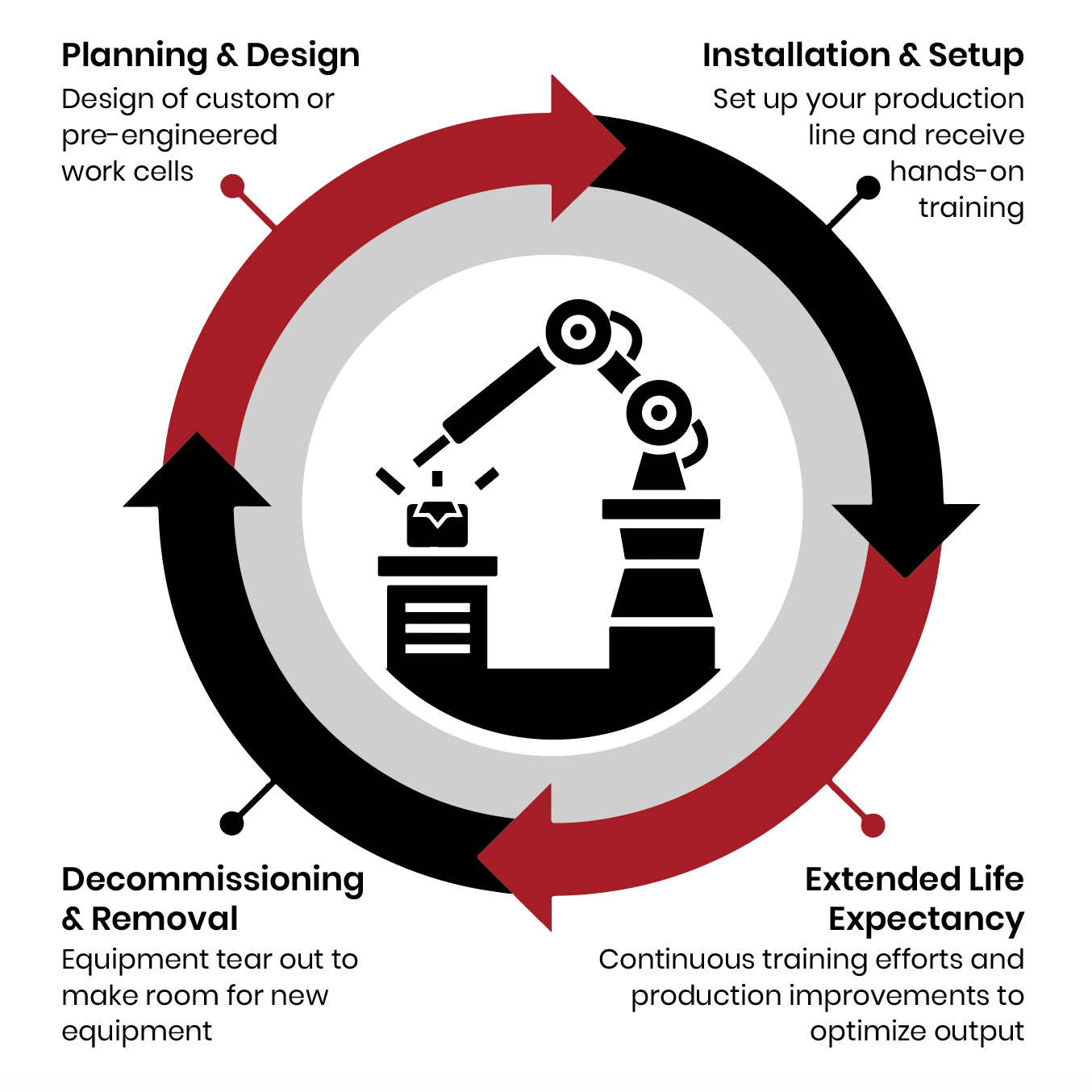

Lifecycle of working with NRTC

Automation

At NRTC, we are driven by our mission, which is to help manufacturers maneuver through the world of automation.

We have a rich history in the industry, which dates back more than a decade ago. Ever since our operations started, we have been driven by the same underlying goal to deliver high-value industrial automation and manufacturing solutions to our customers.

Over the years, we have built our presence in Alabama, Windsor, Canada, and Detroit to serve our customers across North America.

Core services we specialize in

At NRTC Automation, we believe in specialization in crucial areas. That is what makes us better at what we do. We commit specific teams to customer projects to deliver impeccable results.

We offer the following services:

· Decommissioning and tear-outs

· Customized work cells for automated production lines

· Service part manufacturing for all industries

You can also get in touch with us for other services like robot refurbishing, engineering, training, and more.

At NRTC Automation, we have a stiff definition of success. We consider a project successful when it no longer has room for improvement, there are no riddles that need salvaging, and customer satisfaction can no longer get any better.

We are well-equipped and skilled to effectively handle your upcoming industrial automation project. By the time we close up on the project, you can expect more than 200 percent improvement in throughput and capacity.

NRTC Automation lifecycle explained

At NRTC, we have positioned ourselves as your full-service automation provider. When you engage us for your automation needs, you can expect full lifecycle support. That means we start from the ground up until the final phase of automating the production line. We handle all activities from troubleshooting, hiring, training, and eventually tear out. In other words, we help you manage your projects and grow your manufacturing business from start to finish.

Here is a detailed look at our lifecycle.

PHASE 1 – PLANNING AND DESIGN

We don’t start your industrial automation project blindly. Instead, we determine how to ensure your success at the planning and design stage, leveraging the requirements gathered from you to come up with a customized robotic work cell.

Our technicians will take you through everything that’s needed to develop a work cell suited to your needs.

We want to make sure that you have an easy time getting started on the journey to automating your operations. For that reason, we invite you to schedule a free consultation with us to curve the path for efficient manufacturing.

PHASE 2 – INSTALLATION AND SETUP

Once we have the plan and design ready, we immediately get started on bringing the solution to life. Our team of experts will handle the installation process to allow you to continue operations uninterrupted.

After completing the installation and setup, we’ll even help you find the right people to run the work cell.

Upon your request, we will scout for qualified technicians for the automated line. Additionally, we also offer personalized robotics training for your staff to upskill them as needed.

PHASE 3 – ONGOING OPERATIONAL SERVICES

We want to make sure that your equipment is always running smoothly. Thus, at the extended life expectancy phase, we provide services that ascertain uptime. These include services such as industrial maintenance, troubleshooting, robot refurbishing, and repairs.

Our aim is to make sure that you continually operate smoothly and meet your production goals each quarter. We use popular brands like Lincoln Electric, KUKA, and ATI to ensure you have minimal downtime with effective equipment.

PHASE 4 – DECOMMISSIONING AND REMOVAL

At this rate, your company continues to grow and may reach a time when current machinery no longer meets your needs or you are ready to move onto a different project. When that happens, we are available to help you with the decommissioning process.

We buy used assets and recycle equipment to create a broom-ready factory while helping you recoup the initial value of your investment and extend the life of equipment you no longer need. Doing so allows you to easily move on to your next project. Even with that, we can help with the automation requirements.

NRTC has decommissioned facilities for top automotive manufacturers with a 100% on-time success rate. Contact us today to get started on your next project.

NRTC IS YOUR TRUSTED AUTOMATION PARTNER

NRTC Automation seeks to help transition your production line to the next level. We offer services that cover a wide range of industries, be it aerospace, plastics, automotive, and any other.

Contact us today to start engaging you in our revamped automation lifecycle.

Level Up: How do NRTC's Tiers of Robot Refurbishment Differ?

Refurbished robots undergo meticulous repair processes, rebuilding, and cleaning, readying them to continue automating operations.

Refurbished robots undergo meticulous repair processes, rebuilding, and cleaning, readying them to continue automating operations.

NRTC's industrial robots form an important part of the manufacturing sector and a wide range of other industries. Adding them to the production line can prove worthwhile as they introduce many benefits.

One of the crucial benefits of purchasing an industrial robot is enhanced efficiency. Since they are designed for a specific process, they can finish tasks faster and better than humans. As they improve on efficiency, the robots also handle tasks that appear dangerous for humans. That helps improve employees' working conditions and safety.

While considering the many benefits that robots offer, the cost factor tends to limit most people from incorporating the robots into their operations. Refurbishing your robots allows you to save money as you get the same productivity level as a new one. Keep reading to learn more.

NRTC Robot refurbishment tiers explained

When it comes to robot refurbishment, it can be done using two different tiers – Silver or Gold. NRTC uses these two tiers, each of which has a differing implication.

1. Silver Tier

Silver Tier is the standard refurbishment approach where the robot is fully inspected and taken through basic testing. We conduct different types of tests depending on the robot type and model. Generally, we can have performance testing.

NRTC’s Refurbishment Service in action

The goal behind performance testing is to determine how the robot performs in terms of stability and responsiveness under a given workload. Such a test helps us get important information about the robot's speed, reliability, robustness, and application size.

After completing all the basic tests defined under this tier, we will breathe new life into the robot by cleaning it, replacing broken parts, and conducting additional tests to ensure it performs as per the manufacturer's metrics.

Cleaning and disinfection is an important task performed under this tier of industrial robot refurbishing. Any broken parts inhibiting reliability are also promptly replaced to make it functional.

2. Gold Tier

Gold Tier is the high-end option of our two robot refurbishing tiers. It offers a complete refurbishment to like-new conditions and adds to whatever is done under the Silver Tier.

The option works best for those who would like their robot to be stripped down to its core elements and restored to its default factory conditions.

The robot would be taken apart, bit by bit, and each component keenly examined in terms of how it syncs up with the rest of the system. After the enhancements are done and your robot is put together, tested, and proven to be working under its factory conditions, it is further given a paint job. Painting your robot gives it a newer look compared to cleaning.

Should you choose Silver Tier or Gold Tier?

Choosing either Silver Tier or Gold Tier should be considered based on your needs, such as the current condition of your robot, how long you are willing to wait, and the cost factor.

Your robot can undergo standard refurbishment if it maintains optimal performance, has not presented potential safety risks, and has one or two parts that need replacement. Choose this option to put it back into production within the shortest time possible and have a minimal budget for the refurbishment job.

A robot with deteriorating performance is a good candidate for the Gold Tier. At this point, your cost comparison is between the price of a new robot and the cost of refurbishing the one you currently have. Typically, refurbishment is a more cost-effective option than buying a new robot.

Why choose NRTC for robot refurbishment?

NRTC is your trusted and reliable refurbishing partner for the robot. Here is why:

1. We maintain the highest quality standards

At NRTC, we understand the importance of an industrial robot in your business operations. Thus, we ensure that any refurbishment done on it maintains the highest standards possible. Industrial maintenance is done at a high-performance level and in a clean environment. Any robot that we maintain includes a functionality demonstration inspection report, and you will have access to customer support.

2. We guide you through a thorough robot system testing

Don’t just take our word for it after the refurbishment. Apart from the test that we do on our end, we can guide you through any tests that need to be done from a user's perspective. Our technicians can help test-run the refurbished robot to ascertain existing issues have been addressed.

3. Our pricing is transparent

We know that you opted to refurbish the robot and not buy a new one because it helps you to save money as it enhances performance. We won’t make you dig deeper into your pockets with other hidden charges. Honesty and transparency are part of what dozens of top automotive partners love about our services, and we promise to offer the same to you.

NRTC IS YOUR TRUSTED PARTNER FOR ROBOT REFURBISHMENT

At NRTC, we believe in offering top-quality robot refurbishment service. We provide the Silver Tier and Gold Tier to cater to different needs. Whether you want standard refurbishment or a complete strip-down of your robot, we will do it for you. When done, the robot undergoes an inspection and thorough testing before shipping.

Automate with Flexible Robotic Weld Cells

With a robotic weld cell, manufacturers can improve their bottom line by minimizing downtime, reducing lead time, and more.

With a robotic weld cell, manufacturers can improve their bottom line by minimizing downtime, reducing lead time, and more.

Many manufacturing industries require welding applications on the production floor. Robotic welders can help manufacturers meet customer demand and produce better welds while minimizing downtime.

If you are looking to automate your welding applications, then consider choosing a flexible custom weld cell with NRTC Automation. We’ll design, build, and engineer the cell according to your equipment preferences and application needs.

Learn more about automating with a robotic weld cell below.

Automate with a robotic weld cell

Specifications and functionality

While the specifications for each weld cell design differs, and will change based on your needs, we listed some common characteristics of our weld cells below.

Heavy tubular frame

Machinery floor mounts

Safety light curtain integrated into controller

Robot controller & welder mounted on rear for easy movement

Single power point: all power cables, ground cables, and wire conduit routed

Requires minimal floor space

Can be fitted to any welding robots

Comes ready to weld

Sliding rear door for robot maintenance

Our robotic work cells are an all-in-one package constructed to get your welding applications up to speed. With thoughtful design and engineering, you can automate your production line with ease.

Benefits

There are several benefits to adding industrial weld cells to your production line:

Minimal downtime: A robotic welding cell can work extensive hours without breaks, meaning downtime is substantially reduced. Since downtime can cost an average of $5,600 per minute, a robotic welding cell can result in considerable cost savings!

Easy robot maintenance: We design our weld cells with a sliding rear door for easy robot installation and maintenance, further reducing downtime on the production floor.

Precise welds: With high precision and repeatability, this robotic welding cell will produce impeccable welds on nearly every part and product. Improved product quality results in fewer defective products and more satisfied customers.

Reduced lead time: Robotic weld cells can produce more products at a faster rate, effectively reducing lead time to meet greater demand and increase your revenue.

Improved worker safety: A robotic welding cell will take over dangerous and monotonous welding tasks that could result in potential injury. Not only that, but the cell is also complete with steel walls and a safety light curtain for enhanced safety in the workplace.

Experience the benefits of an industrial robotic weld cell by customizing your own through NRTC Automation. We make it easy for you to purchase the equipment you need to grow your company.

Experience the benefits of an industrial robotic weld cell by customizing your own through NRTC Automation. We make it easy for you to purchase the equipment you need to grow your company.

Financing with NRTC Automation

If you are a small- to mid-sized manufacturer who wants to automate without breaking the budget, then consider financing with NRTC Automation.

It’s easy as 1-2-3 to finance with us:

Schedule a consultation with us or give us a call at 888-990-7606 and let us know your automation needs.

We’ll create a quote based on the agreed design specifications.

Submit your financing application to receive the best offers from the nation’s top lenders. The application process takes 60 seconds or less!

Choose the best offer that fits your needs and start automating.

Sign up for a free product pamphlet to see what weld cell best suits your welding applications.

Why Should You Consider Financing?

Manufacturers of any size can finance to enhance production and grow their bottom line.

Manufacturers of any size can finance to enhance production and grow their bottom line.

Optimization is the key to growth in manufacturing.

However, how do you continue to optimize your production line when your budget is stretched to the limit?

Financing allows facility managers to continue to improve manufacturing processes without overstepping the budget.

Learn more about the benefits of financing and how you can finance a custom work cell for your facility below.

Financing industrial automation equipment

Financing versus buying

Financing is the process of applying for a monthly payment plan with payments that are lower than the original lump sum of the product.

Buying outright might make sense in some cases. For example, purchasing several custom work cells in one payment may make sense for mid-sized manufacturers who have the revenue to support that purchase.

Other smaller businesses may struggle to add the equipment they need to their facility due to budget constraints, so they may consider financing instead.

Benefits of financing

Financing is useful for manufacturers of all sizes, phases, and industries.

Low monthly payments: Financing offers lower payments, making industrial automation more accessible for everyone.

Flexibility: With the ability to finance, manufacturers have greater flexibility in their budget to acquire the equipment they need.

Immediate growth capabilities: Manufacturers don’t have to wait until they reach a certain profitability before they expand. Financing allows them to build custom robotic work cells so they can start growing sooner.

Enhanced productivity: Finally, financing equipment enhances productivity because it quickly adds equipment to production that improves throughput and capacity.

Drawbacks of financing

As long as you are purchasing the right equipment, there aren’t many drawbacks to financing.

One downside may be that your purchase is extended across several months rather than at one time, which may make tracking the payments difficult.

However, as long as your budget is in line and orderly, you shouldn’t have to worry about missing a payment.

How to finance with NRTC Automation and iGAM

Are you looking to jump into automation, but don’t know where to start?

NRTC Automation can guide you from start to finish. Our Automation Services will get you on the fast track to start increasing throughput and capacity in your facility. We’ll work with you to design, build, and engineer a custom work cell for your production needs.

We work with top auto manufacturers like Toyota, Ford, and BMW, as well as small- to mid-sized manufacturers looking to grow their businesses. With over a decade of experience, and with our professional engineers and technicians, we provide some of the best automation solutions in the industry.

Need equipment now to boost production? Great! Our sister company, iGAM, is here to help.

iGAM provides two ways to finance:

Fill out the quick application on the product page and choose the best financing plan from the nation’s top lenders.

Apply for credit with our partner Behalf and purchase any equipment you need while making low monthly payments.

Get ahead of the competition and start automating with iGAM and NRTC Automation today.

Build a work cell for your facility

Use NRTC Automation’s Financing Services to minimize downtime and increase throughput on your production floor.

Interested in learning more about what NRTC offers? Schedule a free consultation with us by clicking the button below to get started.

VISIT NRTC AUTOMATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Contact us today to learn more about how we can help you meet your production goals.

Decommissioning Prep with NRTC

Get a clean, spacious facility without the hassle with NRTC Automation.

Get a clean, spacious facility without the hassle with NRTC Automation.

Tear outs don’t have to be complicated. With NRTC Automation’s tried-and-true process, we will complete your decommissioning project within your time requirements with a professional and attentive team.

To make the tear out process faster and easier, check out our steps below on how to prepare for a tear out for the best results.

NRTC’s decommissioning process

Before the start of the project

NRTC recommends that you check off these necessary tasks before a tear out:

Obtain approval: Before a facility is decommissioned, it’s necessary to obtain all approvals from the board and management teams required to move on with the decommissioning process.

Determine the use of the facility: Will your company reuse the facility for a new project, or will a new manufacturer move in to take over the space? Alternatively, the facility may be demolished. Understanding the next phase for the facility will help you plan for the remainder of the tear out.

Figure out your time constraints: Your timeline will be based on the future use of the facility. If another manufacturer or another build is moving into the space, then you will want to leave some room between the end of the decommissioning project and their move-in date.

Manage assets: Decide which equipment will be transferred to another facility for reuse. Once you have completed that step, the remainder of the equipment will be managed by NRTC Automation during the decommissioning process.

Once these tasks are complete, NRTC can start the decommission of your facility.

NRTC in the warehouse

Our Decommissioning Services are thorough and efficient to ensure that we meet your timeline while providing a broom-ready facility at end of service.

3D facility scan: Our 3D technology will provide a layout of your facility as well as photos of all your equipment, allowing NRTC Automation to complete the tear out without delay.

Project manager and team: NRTC will assign a project manager to see your tear out from start to finish. Your project manager will be dedicated solely to your project, as will a team of certified professionals in the manufacturing and industrial automation industries. Our team members will be available throughout the entire project for your tear out needs. You can easily identify them with our NRTC Automation branded safety gear.

Defining key milestones and schedule: Your project manager will define key milestones for your project to keep you updated on the progress of the tear out, as well as a definitive schedule based on your time requirements. The timeline you define will be the one we follow as we decommission your facility. NRTC Automation’s project managers are industry professionals with years of experience to aid you in your tear out. With constant updates on your progress, you’ll never have to worry about the project being sidetracked.

Prioritize safety: Just before the tear out begins, NRTC Automation will post safety signage and set up perimeters to protect our team and yours in dangerous work zones. As mentioned, our team will also wear branded safety gear for easy identification and security. Safety is our priority. Taking precautions as listed by OSHA will allow our team—and yours—to work efficiently without accident or injury.

Check out this graphic to visualize our streamlined process.

NRTC Automation takes your tear outs seriously. That’s why we use our proven process used with partners like Toyota and Mercedes-Benz to clear out your facility.

Once these steps are complete, NRTC will remove equipment and scrap from your facility for a clean warehouse ready for your next project.

Work with NRTC for expert service

Use our checklist above to prepare for NRTC’s Decommissioning Service. Being prepared means you’ll get the most return on your tear out, allowing for a faster process and greater savings.

TALK TO OUR TEAM TO LEARN MORE

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation by clicking the button below.

Spring Ahead in Production: Outsource Parts Manufacturing

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

The saying “It takes a village” holds truth: growth in any form requires extensive support.

Manufacturing is no different. You don’t have to handle all the production under your own roof; by delegating tasks outside of your company, you can focus on what’s important.

Learn more about the benefits of outsourcing parts manufacturing and working with NRTC below!

Outsourcing your parts manufacturing

Your warehouse can only handle so much

From storing parts and materials to running equipment to shipping, there’s a lot going on in a manufacturing warehouse.

You might be reaching the limits of your capabilities depending on the size of your warehouse and the phase of your company’s growth.

Thankfully, that doesn’t mean you have to move into a bigger facility before you’re ready. By outsourcing parts production, you can continue to scale your company according to demand without making sacrifices.

Outsource parts production

Outsourcing is a simple solution to transitory phases in growth, and it’s useful for small and large companies alike. In fact, 39 percent of small companies outsource at least one of their business procedures to save money and resources.

No matter what industry you’re in, outsourcing parts production will help you focus on important manufacturing goals.

NRTC Automation can help. With our Service Parts Manufacturing, you can trust us to create the parts you need with a custom-built work cell made specifically for your company's needs.

We can manufacture parts for any industry: from plastics to aerospace to automotive, we have the tools to supply parts for you.

Benefits of outsourcing your parts manufacturing

Why should you consider outsourcing your parts manufacturing? Well, the benefits extend across your entire company, including:

Increased space: Without the extra materials, equipment, tools, and personnel to produce parts, you’ll have more warehouse space.

Cost savings: Save money by delegating parts production to another company rather than moving to a larger, more expensive facility before you are ready. Additionally, save on energy, labor, and equipment costs associated with parts production.

Enhanced focus: Remove the extraneous production tasks (a common suggestion in lean manufacturing) so your focus won’t be spread thin. Then, you can dedicate time and resources to your main manufacturing goals.

Improved efficiency: By shifting your focus to the important goals, your facility will be more efficient rather than wasting valuable uptime on parts.

Increased scalability: Meet greater demand with more warehouse space and efficient processes to improve your bottom line.

Finding a partner to outsource your parts production will give your company the space it needs to grow. If you want to become competitive in your industry, work with NRTC Automation today.

Prototyping capabilities

On top of parts production, NRTC Automation offers prototyping services. Innovate product design while saving time, money, and manufacturing resources.

Let us bring your ideas to fruition. We’ll work closely with you and create a custom work cell in our warehouse to develop your designs. With a decade of experience, you can trust us to help you transform your business with new, competitive products.

NRTC Automation can manufacture prototypes for as long as you need. Simply contact us or give us a call at (877) 228-2161. We can discuss your prototyping design and turn your vision into a reality.

Spring ahead in production

As you can see, outsourcing parts production and prototyping will not only give you warehouse space and increase efficiency, but it’ll also give you the focus you need to grow your company.

Are you ready to move to the next stage of growth? Decommission your current facility with NRTC to get it into broom-ready condition so you can move with ease.

We’ll assign an experienced project manager and team dedicated solely to your project to finish it on your clock. NRTC has a 100 percent success rate of meeting our partners’ timelines, including top auto manufacturers like Toyota, Mercedes, and BMW. Work with us today to grow your business.

SCHEDULE A FREE CONSULTATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website to schedule a free consultation with us, no strings attached.

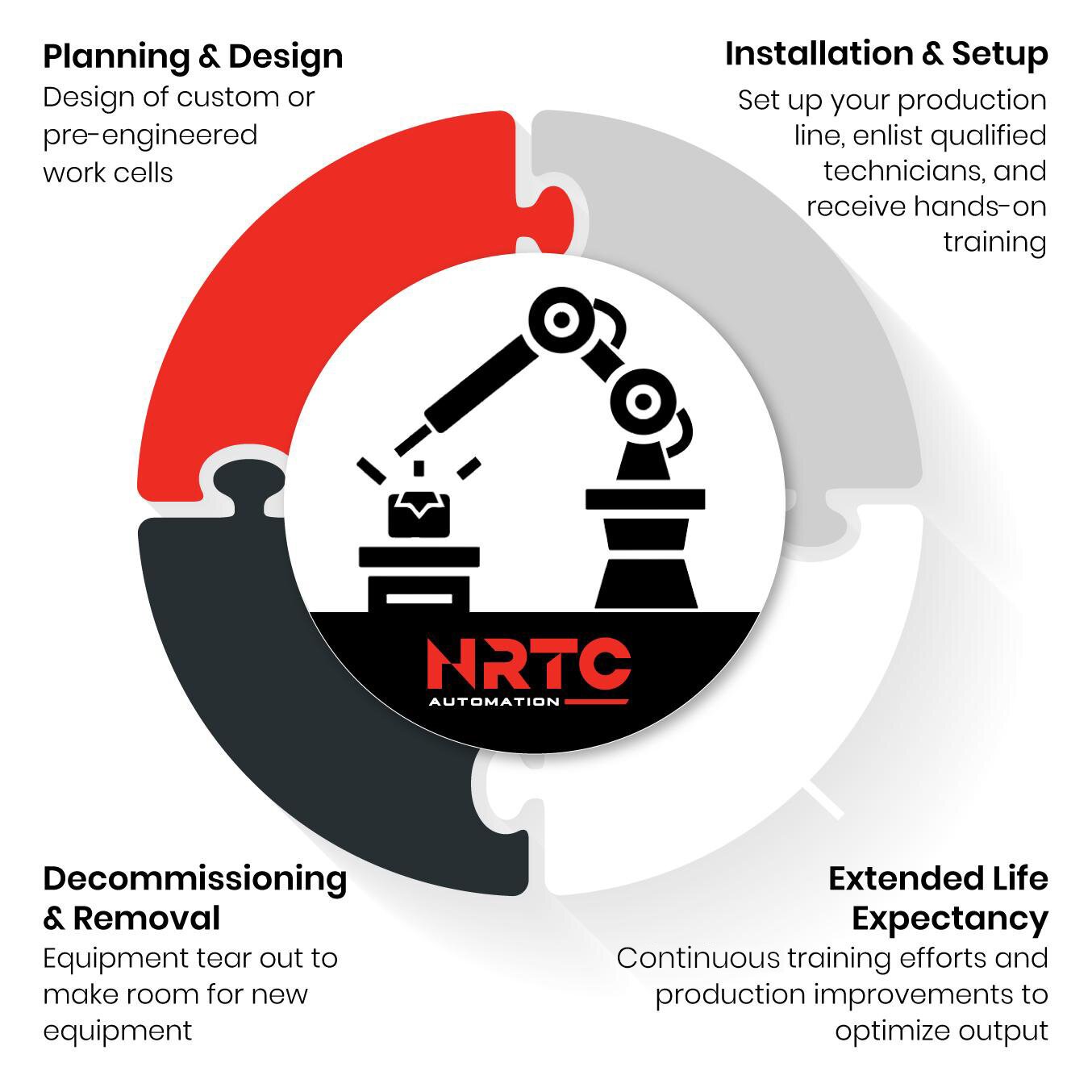

What is the NRTC Lifecycle?

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

NRTC Automation prides itself on providing our customers with services that meet any automation need they might have.

From decommissioning to industrial robot refurbishing to custom work cells, NRTC is your ideal partner for growth in the manufacturing industry.

Learn more about the NRTC Lifecycle and how you can become an NRTC partner below.

Join the NRTC Lifecycle

Who is NRTC Automation?

NRTC Automation was founded over a decade ago, providing decommissioning and automation services for small to large manufacturing facilities.

We are trusted by the world’s top automotive manufacturers, and we continue to preserve our reputation with personalized and deliberate services for our customers.

We are best known for our Decommissioning and Tear Out Services. With a team dedicated to the customer’s project, a project manager that guides the customer every step of the tear out, and our ability to meet deadlines according to the customer’s needs, NRTC Automation sustains our role as leader in providing decommissioning services worldwide.

On top of world-class decommissioning and tear outs, NRTC Automation also offers Service Parts Manufacturing Services and Automation Services.

We can manufacture service parts for your company in our warehouse with a custom-built work cell specific to your design needs. Also, we offer prototyping so our customers can focus on manufacturing while we perfect their product.

NRTC's Automation Services provide turnkey automation solutions for any production line. We’ll design, build, and engineer a custom work cell for you with affordable refurbished equipment. Our customers have reported an increase in throughput and capacity by over 200 percent just by adding our custom work cells to their facility.

Other automation services for a well-rounded manufacturing company include:

Our comprehensive industrial and automation services give manufacturers the ability to stay on top of their production needs and maintain productivity levels.

What is the NRTC Lifecycle?

NRTC Automation aims to be your full-service automation partner. The NRTC Lifecycle means we’ll help you from the ground up to build your automated production line, assist with troubleshooting, hiring, and training, and tear it out when you are ready to move on to your next project.

View our graphic to visualize how NRTC can help you from start to finish.

Planning and Design is the foundation of a solid manufacturing process. This phase starts when we help you design and build your custom robotic work cell. Whether you’re looking to install assembly, arc and spot welding, or material handling robotics into your production line, our technicians will work with you to develop a work cell implementation strategy that meets your demands. By scheduling a free consultation with us, you’ll start on the path to more productive manufacturing.

Installation and Setup provides comprehensive production support. We’ll scout and hire qualified technicians for your now-running automated line, as well as offer robotics training to your employees for well-rounded, educated staff. We create personalized training plans for your company so your employees get exactly the training they need.

During the Extended Life Expectancy phase, NRTC Automation offers services that will keep your equipment operating smoothly. Send your equipment to us for repairs, refurbishment, and troubleshooting to ensure that you’ll meet your production goals every quarter. We work with popular brand name robots and equipment like KUKA, Siemens, and ATI to minimize downtime on your warehouse floor.

Decommissioning and Removal will allow you to grow your company on your timeline. We’ll buy your assets and recycle the rest, leaving you with a broom-ready facility for your next project. With an experienced project manager and a team dedicated to your project, you’ll be impressed with how efficiently and effectively we clean out your facility.

Finally, as your long-term automation partner, we’ll start the cycle again to improve your production processes for the next step in your company’s growth.

What industries can benefit from NRTC’s services?

NRTC Automation works with manufacturers of every industry. From plastics to aerospace to automotive, we have the solutions you need to rise above the competition.

How do I get started?

Visit NRTC Automation’s website! You can schedule a free consultation with us. After discussing your current needs, as well as your vision for the future, we’ll create the best automation plan for your company.

Alternatively, if you know what you need, you can submit a form on any of our service offering pages. Our friendly customer service will get back to you within one business day to discuss your options.

BECOME AN NRTC AUTOMATION PARTNER TODAY

NRTC Automation is a trusted partner providing comprehensive industrial automation and manufacturing services. After delivering our services to top automobile manufacturers across the world for more than a decade, NRTC Automation is the destination for tear out services and robotic solutions.

Visit us today on our website to schedule a free consultation.

We've Achieved ISO 9001 Certification!

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing for our customers across the globe.

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing for our customers across the globe.

By outsourcing your assembly manufacturing, you can minimize downtime, reduce lead time, and improve efficiency on the production floor.

Outsource with a company you trust. NRTC Automation’s parent company, NRTC Alabama Inc., has achieved the ISO 9001 certification to provide you with reliable services.

Learn more about this certification and how it can benefit you below!

NRTC Alabama is ISO 9001 certified

What is ISO 9001?

ISO 9001 is a quality management certification developed by ISO, or the International Organization of Standardization.

This organization was founded in 1947 and has implemented over 23,000 standards in every industry.

Certifications are not audited and registered by ISO; rather, companies like Perry Johnson Registrars, Inc. (PJR) audit and register companies for ISO certifications.

To read the ISO definition of the ISO 9001 standard, visit their website here.

What are we certified for?

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing. We were audited by PJR for the quality management systems of this service.

The official description provided by the certificate from PJR states that we are certified to provide the following scope: “The Manufacture of Precision Machined and/or Fabricated Automotive Assemblies to Customer’s Designs, Specifications, or Requirements.”

We completed the audit process in just under a year in order to offer our customers the peace of mind that they are getting the best services in the industry acknowledged by international standards.

Benefits to our customers

Looking to outsource your assembly manufacturing? NRTC Automation aims to be your preferred partner for your industrial automation and manufacturing needs. With our recent ISO 9001 certification, we are the top choice to provide your assembly manufacturing services.

Our customers benefit from outsourcing to a certified company because:

We can consistently provide high-quality services that meet your demands

We are constantly improving our methods and services to enhance your experience with us

We are regularly audited to maintain our certification status, so you know that you are receiving services from a reputable and dependable company

We meet all requirements set by the ISO 9001 standard because we believe in giving our customers the best the industry has to offer. Work with NRTC Automation to outsource your service assembly manufacturing.

Why should you outsource your assembly manufacturing?

Whether you are a small manufacturer or an enterprise-level business, outsourcing your assembly manufacturing will help you meet your production goals.

Cost savings: Save on labor, energy, and overhead costs dedicated to your assembly manufacturing by sending it to us.

Efficiency: Cut out extraneous production to focus exclusively on your main goals.

Scalability and demand: Respond to greater demand with ease, allowing you to grow your business.

Innovation: You'll have the resources for new ideas and product development when you free up time, space, and money by outsourcing.

Don’t wait to get ahead of the competition and start growing your company. Schedule a free consultation with NRTC Automation today to get a quote for your production needs.

OUTSOURCE YOUR ASSEMBLY MANUFACTURING TO NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website to learn more.

How to Start 2021 with a More Efficient Production Line

With a few changes, manufacturers can remain competitive in 2021 by improving production efficiency.

With a few changes, manufacturers can remain competitive in 2021 by improving production efficiency.

2020 has been a trial for manufacturers around the globe. The COVID-19 pandemic has changed the way we interact and perform in business, and the industry has experienced ups and downs in production.

The New Year can be a promising arrival of growth, but only if manufacturers approach it correctly.

Efficiency is one way to stay competitive in 2021. Learn how to cut waste, improve customer relations, and increase revenue with your production line below.

How to create a more efficient production line

What is slowing down your production?

There could be several reasons why you aren’t reaching peak production efficiency. Some common causes of slow production include:

Not analyzing data and making necessary changes

Turning off production when it can continue to run

Not automating tasks that are monotonous and require high precision

Inadequate labor

Equipment that needs to be repaired, reconditioned, or replaced

Keeping manufacturing processes in-house that can be outsourced

Manufacturing requires constant management and optimization in order to maintain lean, efficient processes.

Benefits of improving production efficiency

There are clearly many benefits to improving production efficiency. When you have an efficient production line, you can:

Improved product quality: Using automation will improve product quality. With high precision and repeatability, industrial robots and equipment can produce better products at a faster rate than human labor. Your employees can move into roles such as operations and customer service, where their creativity and personalities can be utilized.

Reduce operational costs: Cutting inefficiency will reduce operational costs. For example, reducing the amount of waste that is produced during operations will save on material costs. Also, you can cut energy usage by eliminating unnecessary processes during production and reduce your energy bill.

Improve lead time: A faster and more efficient production line will reduce lead time, getting your product to your customers sooner. This means you can fulfill more orders with an efficient production line.

Improve customer satisfaction: Customers that receive high-quality products in a short amount of time will be happier than customers who must wait for products that are susceptible to human error. They will be more likely to come back to your company in the future.

Increase revenue: More orders due to improved lead time, lower operational costs, and happy return customers will inevitably increase your revenue year after year.

Are you interested in learning how to increase production efficiency? Read the four ways you can optimize your manufacturing processes and how NRTC Automation can help below.

4 ways to increase efficiency in your production line

1. AUTOMATE

Implementing industrial automation into your business is the most effective way to improve production efficiency.

One way of doing this is with an all-in-one flexible robotic work cell. If you are new to automation, this is an easy way to automate your production line without having to source, purchase, and engineer the equipment by yourself.

NRTC Automation can build custom work cells that meet the needs of your company. Our customers have increased capacity and throughput by over 200% simply by adding work cells to their manufacturing process.

Learn more about NRTC’s Automation Services on our website.

2. TRAIN YOUR EMPLOYEES

Trained employees are not only more knowledgeable about their work tasks, but they are more productive because they have increased job confidence and satisfaction.

If you want to train your employees in robotics, consider working with NRTC Automation’s Robotic Training Services. We’ll personalize the training program for your business. With our training, your employees will be able to perform basic programming to advanced diagnostics.

3. OUTSOURCE YOUR PARTS MANUFACTURING

If you manufacture parts under your roof, but it isn’t your main focus, you may benefit from outsourcing your parts manufacturing.

These benefits include:

Lower labor costs

Reduced overhead

Increased focus on the main objective

Increased ability to meet demand

NRTC Automation can take on your parts manufacturing. We service multiple industries in manufacturing and will build a custom work cell in our facility solely for your project. Schedule a free consultation with us to learn more about how we can manufacture your parts.

4. HIRE ON-SITE TECHNICIANS

Last but not least, having an on-site technician can save your production line in an emergency. When equipment breaks down and needs to be repaired, you are spending hundreds of thousands of dollars in unplanned downtime.

Rather than trying to find a technician to service your equipment, you can have one on-site to handle breakdowns as they happen.

Are you looking for an experienced robotics technician but can’t seem to find the right fit? Then try out NRTC’s Engineering Services. We’ll find, interview, and hire qualified professionals for your business. Contact us to learn more and find the right team to get the job done.

Stay competitive in 2021 with optimized production

Using lean manufacturing methodology is the key to staying competitive in 2021. Reducing costs and improving customer relationships will increase your revenue and allow your business to continue to grow.

Try out NRTC Automation’s services listed above to optimize your production line today.

WORK WITH NRTC AUTOMATION TO IMPROVE YOUR MANUFACTURING PROCESSES

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers. From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace.

With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us to create an automation plan that suits the needs of your company.

4 Reasons to Outsource Parts Manufacturing

Save precious resources and meet your production goals by outsourcing your parts manufacturing.

Save precious resources and meet your production goals by outsourcing your parts manufacturing.

Businesses should always be on the lookout for ways to trim production costs. One way of doing that is to outsource your parts manufacturing.

Outsourcing work has several advantages that will not only result in cost savings but will also encourage company growth.

Learn more about the benefits of outsourcing parts manufacturing and NRTC Automation’s Service Parts Manufacturing below.

Outsource your parts manufacturing

When should you outsource your parts manufacturing?

Outsourcing parts manufacturing provides companies with space to grow. You can outsource your parts manufacturing whether you are a small business or an established corporation.

If you’re wondering if you should outsource manufacturing, take a look at your costs, as well as focus and flexibility.

COSTS

Two major costs associated with parts manufacturing are labor and overhead.