NRTC AUTOMATION BLOG | INDUSTRIAL ROBOTS AND AUTOMATION

Developing a Successful Production Line

Developing a successful production line isn’t difficult. All you need is a little planning and the right tools. NRTC Automation can help you get there. We are dedicated to providing industrial and manufacturing solutions to all of our customers, big or small.

Developing a successful production line isn’t difficult. All you need is a little planning and the right tools.

In the past 200 years, manufacturing productivity has increased by leaps and bounds with advancements in technologies and automation, making the sky the limit when it comes to production design ideas.

Manufacturers need to plan before implementing or upgrading a production line, and keep in mind elements that will not only serve the company but that will also favor the end product and user.

Read on to discover the steps you should take in order to develop a successful production line.

AUTOMATION IS KEY

Automating is a key factor in implementing a successful production line. And it’s nothing new. Did you know Henry Ford installed the first assembly line in 1913? He was able to reduce the production time for one of his cars from 12 hours to an hour and a half.

Not only does automation improve your manufacturing process, but it also increases revenue while cutting waste from production as well as overhead costs.

NRTC Automation produces pre-engineered and customized work cells, that are the ultimate turnkey solution. Our work cells include specialized robotic systems that cover your manufacturing needs from top to bottom.

Adding elements like robotic arms to your production line can increase productivity and improve product quality. Additionally, they keep costs low and reduce the risk factors in dangerous or demanding environments.

DEVELOPING AND IMPLEMENTING A MAINTENANCE PLAN

Ensuring a production line stays successful can hinge on its maintenance plan. Production lines consist of a variety of elements, and each one will have its own set of maintenance requirements. Developing and implementing a preventative maintenance plan will protect equipment from failing or breaking down.

Starting with a predictive plan, and not a reactive approach, will ensure less downtime for your production line. A recent GE study found that only 24% of operators described their maintenance approach as “predictive” resulting in a 5.42% annual unplanned downtime vs 8.43% for those adopting a “reactive approach”.

Routine maintenance should include replacing old or worn parts, cleaning out and changing old grease, replacing filters, refreshing paint jobs, and replacing batteries. Keeping maintenance tasks like these on a schedule allows your equipment to work as efficiently as possible, saving you downtime as well as money from purchasing new equipment.

NRTC offers industrial refurbishment services, from basic evaluations to complete overhauls. We can help extend the life of your robots and production line and return their functionality to the highest caliber.

LEAN MANUFACTURING METHODOLOGY

Lean manufacturing is one of the most effective ways to make sure your production line is in the best shape possible. Keeping a lean methodology aims at reducing waste to improve the efficiency of production. Less waste equals less energy.

There are many different methodologies you can implement, such as 3P, Six Sigma, and Kaizen. Learn more about these methods on the NRTC Automation glossary page.

Start your Successful Production Line Today

Efficiency is fundamental to success in today’s market, and NRTC Automation can help you get there. We are dedicated to providing industrial and manufacturing solutions to all of our customers, big or small. From automation solutions and turnkey weld cells, to robot refurbishing and engineering contract services, we have you covered.

Contact us for a free quote and see how we can help you develop a successful production line.

4 Reasons a Turnkey Work Cell Will Improve Your Production

Turnkey weld cells are an easy way to implement efficiency and productivity in manufacturing and production. Adding turnkey weld cells can keep companies on the cutting edge and reduce waste.

Turnkey weld cells are an easy way to implement efficiency and productivity in manufacturing and production. Adding turnkey weld cells can keep companies on the cutting edge and reduce waste.

Cells can be either pre-manufactured or customized for the specific needs of a company or production line. NRTC Automation can design, engineer, and build a turnkey weld cell to fit all of your production needs.

Read on to find out four reasons a turnkey work cell will improve your company’s production and why you should add one to your manufacturing set up.

INCREASE PRODUCTION

One of the most enticing factors of a turnkey weld cell is its ability to increase production rates, without sacrificing quality. Adding work cells creates less of a margin of error than using manual labor, and has higher repeatability compared to in-house human workers.

Many companies are also implementing turnkey weld cells with cobots, collaborative robots that work safely and seamlessly with humans, and have a lower price point.

There are also companies that are installing turnkey weld cells into their fully automated facilities, streamlining the entire warehouse. These so-called dark warehouses are able to operate 24/7 and increase production through automation and AI.

SAVE MONEY

Implementing turnkey work cells is a cost-efficient method of production. Not only can turnkey weld cells replace expensive labor costs, but installing automation with work cells often solves the problem of staffing when there are shortages.

A work cell is less expensive than buying new equipment individually and adding a custom turnkey weld cell to your facility can save you money in the long haul by increasing efficiency and production run time.

Utilizing a turnkey work cell also minimizes downtime when manufacturing, which can cost an average of $260,000 per hour. The average downtime of production is roughly four hours, which can end up with an average cost of $2 million.

A robotic weld cell reduces that downtime with a constant workflow. Having, for example, a work cell with automatic tool changers allows robots to quickly change applications, and speed up delays.

Additionally, robots don’t require light or air conditioning, so manufacturers are able to save even more money by cutting costs for heating, cooling, and lighting.

HIGHER QUALITY PRODUCT

Implementing a turnkey weld cell increases the quality of your product, due to its high repeatability and precision. Self-contained in one cell, automation production assembles, welds, dispenses, and more. Choosing a well-planned robotic work cell, or using a custom design to fit your needs, can overall enhance your product quality.

Choosing a partner like NRTC Automation ensures that you are being delivered high-quality services that will not only improve your manufacturing processes, but increase your revenue and cut production waste.

A TOTAL SOLUTION

A turnkey weld cell is an all-in-one solution to all your automation needs. Pick and choose the robots and their functions to fit your manufacturing needs. NRTC offers pre-engineered and customized work cells that are the ultimate turnkey solution.

For companies of all sizes, a turnkey work cell is an easy and affordable way to effortlessly automate your company.

NRTC is the Source for Automation Solutions

We at NRTC Automation are dedicated to providing industrial automation and manufacturing solutions. Along with decommissioning and industrial robotic training services, NRTC is the key to integrating and streamlining your production facility.

Contact NRTC Automation today to find out all the ways we can help you automate.

Why should you Outsource Parts Manufacturing?

As manufacturing moves back into the United States, moving production in-house has been on the minds of many businesses. While moving production in-house does have its benefits, there are many reasons to continue to outsource parts manufacturing.

Designing Your Weld Cell - 3 Things You Need to Know

Robotic weld cells can help production lines increase productivity and efficiency, as well as keeping costs lower. While individual industrial robots can be great, weld cells are pre-engineered to run production according to a job specific need.

In a constantly evolving competitive economy, adding elements like robotic weld cells keep companies on the cutting edge and able to focus on efficiency. And with many production cells cutting down on waste, there is not only higher profit, but an increasingly better relationship with the environment.

There are important steps and processes to consider as you are designing a weld cell for a production line.

Continue reading to learn three things you need to know before designing your weld cell.

MAKE A PLAN

It seems like a simple and straightforward idea, but knowing exactly what your work cell needs to do is an important first step when designing. Asking questions like, “What will my work cell be producing?” is key to knowing exactly what parts to include in the cell, and how to program it.

Each work cell that is in existence has not only specialized parts, but unique programming to both the task and machine. Being as specific as possible in this early stage helps streamline building and programming, and ensures less down time as you start to design.

Part of making a plan should be developing an outline, including mapping out tasks before production and building begins. A solid outline will act as a framework for production, and make sure all steps of the automation process will be included.

PICK YOUR PLAYERS

Once a thorough plan is created with an outline, it’s time to select the industrial robots and parts for your weld cell. As you are searching for robots, there are a few important points that should be considered:

Robots' Reachability – This can determine the number of robots and spacing.

Payload Limitations – Consider what you are producing, and the weight and size limitations of the equipment you are selecting.

Precision Capabilities – Determining what you will be producing and the finer nuisances that might be needed can separate one robot choice from another.

End of Arm Tooling (EOAT) - Knowing what equipment you will need on the end of your robotic arm can help to narrow down purchasing options.

Cycle of Time – The speed of the robot is a good indicator for a production line’s efficiency and speed.

In considering what robots to select, a positioner also needs to be chosen. The positioner is what will hold or contain your product that is being manufactured. It can be mobile or fixed, with factors such as adjustable height and weight capacity being taken into consideration when selecting an option.

LAY IT ALL OUT

Once you’ve developed an outline, and selected your production equipment, it’s time to create a layout. This is the most important aspect of design, as you are figuring out the placement of both robots and positioners to achieve maximum efficiency.

Consider how your work cell will be laid out. Will it be in a linear fashion, or will it have turns, or changes in direction?

As you lay it out, make sure to think about not only how it will fit into a manufacturing facility, but how staff and employees will be positioned in the workflow. Safety is always the most important factor, and protecting and making sure employees are comfortable should be a top priority.

NRTC Automation Solutions

NRTC specializes in custom turnkey weld cells for manufacturers of all sizes. From startups to top automotive OEMs, all of our work cells are refurbished, ensuring turnkey automation that is ready-to-work and affordable.

For more information on our automation solutions, turnkey weld cells, and parts manufacturing, contact us or visit our website for more information.

3 Ways to Improve Efficiency in your Production Line

Production lines are installed in industrial manufacturing to increase production and efficiency. But what happens when those lines begin to slow, waste money, energy and ultimately affect a company’s bottom line?

Production lines are installed in industrial manufacturing to increase production and efficiency. But what happens when those lines begin to slow, waste money, energy and ultimately affect a company’s bottom line?

It’s important to be aware of signs a production line is being inefficient, and how to improve performance.

Read on to learn more about ways to improve efficiency in your own production line.

RECONDITION YOUR EQUIPMENT

Production lines rely on manufacturing equipment and industrial robots to be in prime condition in order to keep processes as efficient as possible. Over time, even new machines purchased will begin to show wear and tear, and it’s important to know the signs to spot when it’s time to give your equipment new life.

Routine maintenance is key to staying on top of repairs or cleaning that might need to happen in order to keep your industrial robot or machine running like new. Finding a balance between regular updates and downtime is important when evaluating the maintenance schedule. If more repairs and upkeep are required over time, it may be an opportunity for reconditioning your equipment. Reconditioning extends the life of machinery and can involve something as simple as a deep clean, removing dust, grease, and other items, or replacing old parts.

NRTC Automation offers two levels of reconditioning services, which are tailored to your individual requirements, as well as offering industrial robot painting services and repairs.

EMPLOYEE TRAINING

Although manufacturing automation depends largely on robotics and machinery, the employees of a business, especially a production facility, are just as, if not more, important than the production line itself.

Employees need to stay engaged and informed, with regular meetings and cross-training. A regular meeting schedule with staff can not only keep employees abreast of any future changes or updates, but also keeps a line of communication open for employees to express problems on the floor or with current machinery or industrial robots.

Additional training, such as cross-training, allows for a wider net of safety and information to be cast over a production facility. If an employee can understand the entire production process, they are then able to assist others in different roles if needed or to fill production gaps.

NRTC provides robotic training services for industrial manufacturers and production facilities, allowing for employees to keep up-to-date on new information, technology, and processes.

UPGRADING SYSTEMS

If an industrial robot is passed the point of being able to be reconditioned, it is worth it to look into replacing the machinery. Often times, replacing a system can be more cost-effective in the long run than continually repairing and reconditioning it.

Purchasing a newer, but still used, high-quality machine or robot is a price-saving practice that can still upgrade production without breaking a budget. Our sister company iGAM has multiple options for high-end used industrial machines and robots.

Additionally, implementing lean manufacturing processes that create less waste can improve production efficiency, save costs, and of course, positively impact the environment. NRTC Automation specialized in designing, engineering and building custom, turnkey robotic work cells that can increase productivity and efficiency in your production line.

NRTC CAN HELP

NRTC Automation helps manufacturers of all sizes with automation, training, and robotic solutions to fit every need and keep production efficient. We offer custom turnkey weld cells, engineering contract services, and more. To learn additional information, or to contact our team, visit us here.

How Will Manufacturing Facilities Change in the Next 10 Years?

Manufacturing is a rapidly changing industry. With constantly updating technology and a shift in the industry in response to COVID-19, the outlook for the next ten years has been rapidly changing and coming into focus. Industrial machinery and robotics are evolving to streamline production and change with the tides as we progress into the new century.

Manufacturing is a rapidly changing industry. With constantly updating technology and a shift in the industry in response to COVID-19, the outlook for the next ten years has been rapidly changing and coming into focus. Industrial machinery and robotics are evolving to streamline production and change with the tides as we progress into the new century.

Read on to learn more about the ways manufacturing facilities will change in the coming years.

How will Manufacturing Evolve?

Predictive Maintenance Will Take the Forefront

Predictive maintenance uses computer AI and sensors installed throughout production lines to proactively alert operators of potential maintenance issues or failures. If manufacturers can stay on top of potential issues, there will likely be less downtime and issues with production.

As technology advances, manufacturers are not just purchasing newer industrial machines and robots with these sensors but installing them on older equipment. Manufacturers that have done this are able to analyze data and then interpret a machine’s condition, fix machines before they break or fail, and find irregularities that may lead to downtime.

Real-Time Manufacturing

Over the past few years with the effect that COVID-19 had on production facilities, many industries are moving to a thinner and scaled-back inventory. Automation and AI are helping manufacturers keep only what is necessary on the shelves and using their current technologies, machines, and industrial robots to keep supplies moving through the production line as soon as they enter the building.

Efficiency will be ramp up and create more space in a warehouse, allowing companies to expand and increase production.

Infection Control through Automation

Coronavirus changed the way many businesses functioned and influenced the way employers looked at health issues within their facility. Masks, hand sanitizers, and additional health protocols were put in place across the world in order to curb the spreading virus, and many of those are still in place today. And one of the biggest moves that companies made included adding robots to their assembly lines and production facilities.

Industrial robots and machines don’t get sick, and therefore don’t take sick days or need recovery time. Many manufacturers have implemented automation and replaced human workers with robots as a preventative measure, should a worldwide pandemic strike again. Production can be maintained with industrial automation, and human interaction can stay contained and limited.

As technologies grow, robots and automation replacements are becoming increasingly widespread. Today, there are even fully-automated factories and job sites known as “dark factories” that require no direct human interaction on-site.

Working with Robots

Manufacturers aren't just looking to replace their employees with robots, but they are also searching for ways to integrate robots with their employees. These “cobots” work side-by-side with humans in warehouses and production lines in collaborative environments.

Not only can cobots assist with efficiency, but they also aid in maintaining safety protocols, performing tasks like heavy lifting or working with extreme heat sources without risk of injury. Intelligent robots can work in tandem with employees on the floor, speeding up production and increasing efficiency.

Sustainability Focus

Manufacturers are moving toward greener and more sustainable production methods, thanks not only to public pressure and scrutiny, but also government efforts like the Clean Water and Clean Air Acts. Refurbishment of existing robots and machinery keeps costs, as well as environmental impacts, low.

Buying used machinery reduces carbon dioxide emissions, and other types of pollution, and can be updated to fit seamlessly into production lines. When an industrial machine can no longer be used, companies are learning how to properly dispose of machines without just tossing them out with the trash.

Our partner HGR works to recycle up to 95% of most industrial machines that cannot be resold or repurposed, helping to keep pollutants out of landfills and the environment.

NRTC Automation Keep You Updated

NRTC Automation ensures our customers are at the forefront of changes in the industry and keeping with up-to-date technology.

Whether we are helping to update and automate your facility, or designing a custom part for your newly refurbished industrial robot, NRTC can assist businesses in moving forward. To learn more about how our services could positively impact your production, visit our website.

The Guide to Industrial Automation Terms You Might Not Know

Deepen your understanding of industrial automation and manufacturing systems with these popular terms.

Deepen your understanding of industrial automation and manufacturing systems with these popular terms.

Whether you are a business owner looking into upgrading and streamlining production, or you are part of a large corporation moving to a new facility, there are many terminologies involved in automation and equipment removal. These terms may sound foreign to someone outside the manufacturing industry.

Read more below to familiarize yourself with a few common terms used in the industrial automation industry.

Industrial Automation Terms to Know

Decommissioning

Decommissioning involves removing equipment from a facility that are no longer in use. This could be one item to entire plants of equipment. NRTC Automation offers decommissioning services on various scales, from standalone industrial robots to large scale facilities and production lines.

We offer comprehensive decommissioning services with an emphasis on safety, speed, and efficiency, extracting all equipment and machinery and providing a broom-ready facility.

Industrial Automation

Industrial automation is a process that reduces the needs for human interaction in a manufacturing or industrial process. This streamlines the manufacturing process and increases revenue, while also cutting overhead costs and production waste.

NRTC Automation produces pre-engineered and customized work cells, providing your business with a turnkey solution.

Industrial Refurbishment

When it’s too expensive to purchase new equipment or machinery, refurbishment is a great alternative. Industrial refurbishment can include cleaning, painting, repair or replacement of broken parts, or restoring machinery to factory conditions.

Regular maintenance of industrial robots and machinery, including refurbishment, prolongs the lifespan of the item, as well as returning functionality that may have been deteriorating over time. NRTC Automation offers two levels of Industrial Robot Refurbishing Services, Silver and Gold, based on a customer’s needs and the state of the machinery that needs work.

IoT

The IoT, or Internet of Things, is a term used to describe a network of machines, robots, data, objects and even people. In a manufacturing facility, the “things” included in the internet of things can be anything from industrial robots, conveyor belts, and any part of the automation or production process, as long it is connected with a data flow.

Think of an IoT as an internal ecosystem, sharing information. For the most part, IoT are self-sufficient work flows, without the interference of a person, although interaction with a device or machine might be part of the process.

CNC Machine

CNC stands for Computer Numerical Control. A CNC Machine is a computer run manufacturing process that controls machinery, including tools, automatically through preprogrammed commands. This is as opposed to something that would have to be guided manually.

CNC Machine is a broad term, and can include lathes, CNC routers, mills, grinders, and other forms of industrial machinery. CNC Machines help to streamline production, and can unify multiple steps of a task into one machine using a single set of programmable computer commands.

Augmented Reality

Augmented realty, or AR, is the combination of a virtual world generated by a computer with a real world. Beginning with a real-world image, it is then augmented with different layers of digital information.

AR allows companies to get insight into working conditions, equipment operating statuses, and more. It is an effective way to monitor a manufacturing process, and get ahead of any problems that might occur.

Turnkey Weld Cells

NRTC Automation provides manufactures of all sizes with turnkey weld cells—predesigned robotic cells that help propel a company into automation.

Ready to be installed and go to work, they are great for getting started into automation, before a production facility is ready to design a customized weld cell. All NRTC robots in our work cells are refurbished, allowing for an affordable solution that is ready to go to work.

NRTC AUTOMATION SERVICES

Even if you are brand new to industrial automation, NRTC Automation is here to help. These are just a few of the common terms used in manufacturing development, automation, and decommissioning. You can learn even more from the online glossary available on our website.

Our goal is to help manufacturers maneuver through the world of automation. Whether it be through decommissioning and tear outs, service parts manufacturing, or custom building you a work cell to automate your production lines, we have you covered. Plus, we offer training, engineering, robot refurbishing and more.

Learn more about everything NRTC Automation has to offer today by contacting our team here.

History of NRTC Automation

After a decade of growth and opportunity, NRTC Automation has established itself as the choice partner for comprehensive industrial automation and manufacturing solutions.

After a decade of growth and opportunity, NRTC Automation has established itself as the choice partner for comprehensive industrial automation and manufacturing solutions.

Learning about the history of a company is a great way to understand their mission and expertise.

At NRTC Automation, we have a multi-faceted history of growth and development that led us to become the full-service automation solutions company that we are today.

Learn more about NRTC’s history and how we can help you meet your production goals below.

History of NRTC Automation

THE VERY BEGINNING

NRTC Automation (and our sister company, iGAM) falls under the parent company NRTC Alabama.

Over a decade ago in Tilbury, Ontario, NRTC Alabama was founded under the name New Rubber Technologies by Mike Vagi.

Mike, our current President of Sales and co-founder of iGAM, is a highly driven and successful entrepreneur. He has over 20 years of experience starting and growing companies from the conceptual stage to fully operational organizations with over 100 employees.

New Rubber Technologies was a rubber reclamation business. The company would collect rubber from tire yards and other demolition sites and, using a rubber grinding machine, vulcanize the rubber into a usable product.

Not too long after New Rubber Technologies started up, Mike discovered that to get to the next level in his business, he needed an industrial robot. He decided to join an auction and found six robots available at a good price.

Even though he only needed one robot to complete the job, Mike purchased all six robots, unsure of what he was going to do with them at first. Mike decided to call one of his contacts and struck a deal with him to sell five robots for a great price.

MAKING GROUND IN THE WORLD OF AUTOMATION

This deal marked a major shift in our business, from only doing rubber recycling to also participating in robot auctions.

In 2011, Mike bid on over 100 decommissioned Kawasaki robots against another company. He won the bid and sold some of the robots to the company where Dan Hill used to work. Mike and Dan met for the first time and helped the company build its presence through automation.

The excitement of helping another company grow through automation gave Mike the idea to build our own inventory of automation equipment to provide our customers with a better deal. Around 2014, New Robot Technologies shifted into NRT Equipment Sales to provide manufacturers with affordable automation equipment.

A major turning point for our company was when we sold our first single, double, and triple spot weld cells in 2015, and started receiving more orders from other businesses such as prototyping companies.

Finally in 2018, we broke through as a reputable industrial automation company. We were hired to design, build, and engineer nine automated cells in only 10 weeks. While this was a challenging opportunity, Mike and the team took it on with eager determination, providing quality automation cells to a company looking to move to the next level of growth.

NEW GROWTH

After the work cell project, NRT Equipment Sales received another opportunity to help a large customer decommission their current facility and build a new facility with an entire paint line from scratch. While doing the e-coat work and implementing the line into the facility, Mike and Dan started discussing service parts manufacturing in Alabama.

Dan joined the company and moved to Alabama in April of 2019 to start working on the new facility for NRT’s next adventure in the United States. We started out with a 50,000 square foot facility and shipped a hood, the first service part we produced as a company, on August 5th, 2019.

Around the same time, iGAM, the online marketplace for industrial robots and manufacturing equipment, was founded alongside our newly established name, NRTC Automation.

WHERE WE ARE TODAY

NRTC Automation and iGAM have come a long way since the summer of 2019.

We’ve established locations in Alabama, Georgia, South Carolina, Canada, and Michigan, and our team has grown to nearly one hundred employees since Dan started.

Now, on top of Decommissioning and Tear Outs, Automation Services, and Service Parts Manufacturing, NRTC Automation also offers services so manufacturers receive help every step of the way through the automation journey:

Industrial Robot Refurbishing

Prototyping

Robotic Engineering

Robotic Training

Industrial Tool and Fixture Storage

The best part about NRTC Automation’s growth is that we provide a solution for every industrial automation and manufacturing need. We work with our customers to help them meet their production goals from start to finish, which helps us grow in the process.

Plus, our employees benefit from working with us, too. They get a complete picture of the automation process and gain meaningful experience in how to help manufacturers grow their companies with automation, training, troubleshooting, and more.

SCHEDULE A FREE CONSULTATION

All around, NRTC Automation is the best place to go for manufacturers of any size and phase looking to optimize production, minimize downtime, and build their revenue. We have a consistent track record of high-quality performance, as shown by our partnerships with top automotive manufacturers like Toyota, BMW, and Mercedes, as well as small- to mid-sized manufacturers.

With a wide range of automation services and capabilities, NRTC Automation can help. Our team of experienced and qualified professionals will support you in your journey to growth.

Schedule a free consultation with NRTC today to see what it’s like working on your production needs with us.

NRTC AUTOMATION IS YOUR PREFERRED PARTNER

NRTC Automation is dedicated to providing high value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrating into your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Contact us today to learn more about how we can help you meet your production goals.

We’ve Been Nominated for Manufacturer of the Year Award

NRTC Automation is honored to be recognized for our commitment to our customers.

NRTC Automation is honored to be recognized for our commitment to our customers.

We are excited to announce that the Business Council of Alabama has nominated NRTC Automation for the Alabama Manufacturer of the Year Award!

NRTC Automation serves the local Alabama community from our Birmingham warehouse, as well as internationally.

It is an honor to be acknowledged for our efforts, especially during a pandemic. NRTC is known for our dedication to quality service and expertise in industrial automation and decommissioning services.

We thank the Business Council of Alabama for our nomination and continue to offer our customers the best service we can provide.

Learn more about the award and NRTC Automation’s services below.

Alabama Manufacturer of the Year Award

What is the Alabama Manufacturer of the Year Award?

This award has been offered annually since the turn of the 21st century.

According to their website, the awards “recognize the state's top manufacturers for their accomplishments. By applying for the award, manufacturers convey their story of financial growth, manufacturing leadership, market leadership, leadership development, and workforce enhancement.”

Sponsors of the award include the Alabama Technology Network, the Business Council of Alabama, and Alabama Automotive Manufacturers Association.

This award supports Alabama’s manufacturing industry by recognizing the achievements of manufacturers, promoting better products and service to the public.

NRTC Automation is proud of our commitment to our customers

At NRTC Automation, we help manufacturers maneuver through the world of automation. Your growth is our mission.

We provide a customized solution for the decommissioning and tear out of your manufacturing and industrial assets. Our focus is on minimizing disruption and downtime in the work area while emphasizing safety, speed, and efficiency.

We also provide additional services to help ensure full adoption of automation solutions and a seamless integration into your workplace, such as:

NRTC was founded over a decade ago in Tilbury, Ontario with the goal of delivering high-value industrial automation and manufacturing equipment solutions to all our customers.

With partners from small manufacturers to global manufacturers like Toyota and Ford, we have the experience needed to get you where you want your production to be. Trust us to help with your next industrial automation project.

Working with iGAM under NRTC Alabama, Inc.

NRTC Alabama, Inc. is an industrial automation services company. For over a decade, we have provided full-service solutions to assist manufacturers through every step of automating their facilities.

Under NRTC Alabama, Inc., NRTC Automation and iGAM work together to guide our customers from purchasing industrial equipment and parts to optimizing their production lines.

iGAM is the online marketplace for used industrial robots, robot parts, and manufacturing equipment. With competitive pricing, flexible financing options, and ready-to-work equipment, iGAM is the solution for manufacturers of any size looking to automate their facilities. Plus, iGAM offers asset appraisal services so customers can determine the value of their equipment.

Together, NRTC Alabama’s brands make automation accessible for manufacturers in every industry.

Follow us on social media

To stay updated on NRTC Automation and iGAM, follow us social media!

You can find NRTC Automation on:

And you can follow iGAM here:

We post several times a week, sharing the latest industry news, product sales, entertaining memes, content of our team, and more. Join in on the fun!

Also, check out our blog for more weekly articles on the industry.

VISIT NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation today to have our experts assess your industrial automation needs.

Spring Ahead in Production: Outsource Parts Manufacturing

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

The saying “It takes a village” holds truth: growth in any form requires extensive support.

Manufacturing is no different. You don’t have to handle all the production under your own roof; by delegating tasks outside of your company, you can focus on what’s important.

Learn more about the benefits of outsourcing parts manufacturing and working with NRTC below!

Outsourcing your parts manufacturing

Your warehouse can only handle so much

From storing parts and materials to running equipment to shipping, there’s a lot going on in a manufacturing warehouse.

You might be reaching the limits of your capabilities depending on the size of your warehouse and the phase of your company’s growth.

Thankfully, that doesn’t mean you have to move into a bigger facility before you’re ready. By outsourcing parts production, you can continue to scale your company according to demand without making sacrifices.

Outsource parts production

Outsourcing is a simple solution to transitory phases in growth, and it’s useful for small and large companies alike. In fact, 39 percent of small companies outsource at least one of their business procedures to save money and resources.

No matter what industry you’re in, outsourcing parts production will help you focus on important manufacturing goals.

NRTC Automation can help. With our Service Parts Manufacturing, you can trust us to create the parts you need with a custom-built work cell made specifically for your company's needs.

We can manufacture parts for any industry: from plastics to aerospace to automotive, we have the tools to supply parts for you.

Benefits of outsourcing your parts manufacturing

Why should you consider outsourcing your parts manufacturing? Well, the benefits extend across your entire company, including:

Increased space: Without the extra materials, equipment, tools, and personnel to produce parts, you’ll have more warehouse space.

Cost savings: Save money by delegating parts production to another company rather than moving to a larger, more expensive facility before you are ready. Additionally, save on energy, labor, and equipment costs associated with parts production.

Enhanced focus: Remove the extraneous production tasks (a common suggestion in lean manufacturing) so your focus won’t be spread thin. Then, you can dedicate time and resources to your main manufacturing goals.

Improved efficiency: By shifting your focus to the important goals, your facility will be more efficient rather than wasting valuable uptime on parts.

Increased scalability: Meet greater demand with more warehouse space and efficient processes to improve your bottom line.

Finding a partner to outsource your parts production will give your company the space it needs to grow. If you want to become competitive in your industry, work with NRTC Automation today.

Prototyping capabilities

On top of parts production, NRTC Automation offers prototyping services. Innovate product design while saving time, money, and manufacturing resources.

Let us bring your ideas to fruition. We’ll work closely with you and create a custom work cell in our warehouse to develop your designs. With a decade of experience, you can trust us to help you transform your business with new, competitive products.

NRTC Automation can manufacture prototypes for as long as you need. Simply contact us or give us a call at (877) 228-2161. We can discuss your prototyping design and turn your vision into a reality.

Spring ahead in production

As you can see, outsourcing parts production and prototyping will not only give you warehouse space and increase efficiency, but it’ll also give you the focus you need to grow your company.

Are you ready to move to the next stage of growth? Decommission your current facility with NRTC to get it into broom-ready condition so you can move with ease.

We’ll assign an experienced project manager and team dedicated solely to your project to finish it on your clock. NRTC has a 100 percent success rate of meeting our partners’ timelines, including top auto manufacturers like Toyota, Mercedes, and BMW. Work with us today to grow your business.

SCHEDULE A FREE CONSULTATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website to schedule a free consultation with us, no strings attached.

What is the NRTC Lifecycle?

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

NRTC Automation prides itself on providing our customers with services that meet any automation need they might have.

From decommissioning to industrial robot refurbishing to custom work cells, NRTC is your ideal partner for growth in the manufacturing industry.

Learn more about the NRTC Lifecycle and how you can become an NRTC partner below.

Join the NRTC Lifecycle

Who is NRTC Automation?

NRTC Automation was founded over a decade ago, providing decommissioning and automation services for small to large manufacturing facilities.

We are trusted by the world’s top automotive manufacturers, and we continue to preserve our reputation with personalized and deliberate services for our customers.

We are best known for our Decommissioning and Tear Out Services. With a team dedicated to the customer’s project, a project manager that guides the customer every step of the tear out, and our ability to meet deadlines according to the customer’s needs, NRTC Automation sustains our role as leader in providing decommissioning services worldwide.

On top of world-class decommissioning and tear outs, NRTC Automation also offers Service Parts Manufacturing Services and Automation Services.

We can manufacture service parts for your company in our warehouse with a custom-built work cell specific to your design needs. Also, we offer prototyping so our customers can focus on manufacturing while we perfect their product.

NRTC's Automation Services provide turnkey automation solutions for any production line. We’ll design, build, and engineer a custom work cell for you with affordable refurbished equipment. Our customers have reported an increase in throughput and capacity by over 200 percent just by adding our custom work cells to their facility.

Other automation services for a well-rounded manufacturing company include:

Our comprehensive industrial and automation services give manufacturers the ability to stay on top of their production needs and maintain productivity levels.

What is the NRTC Lifecycle?

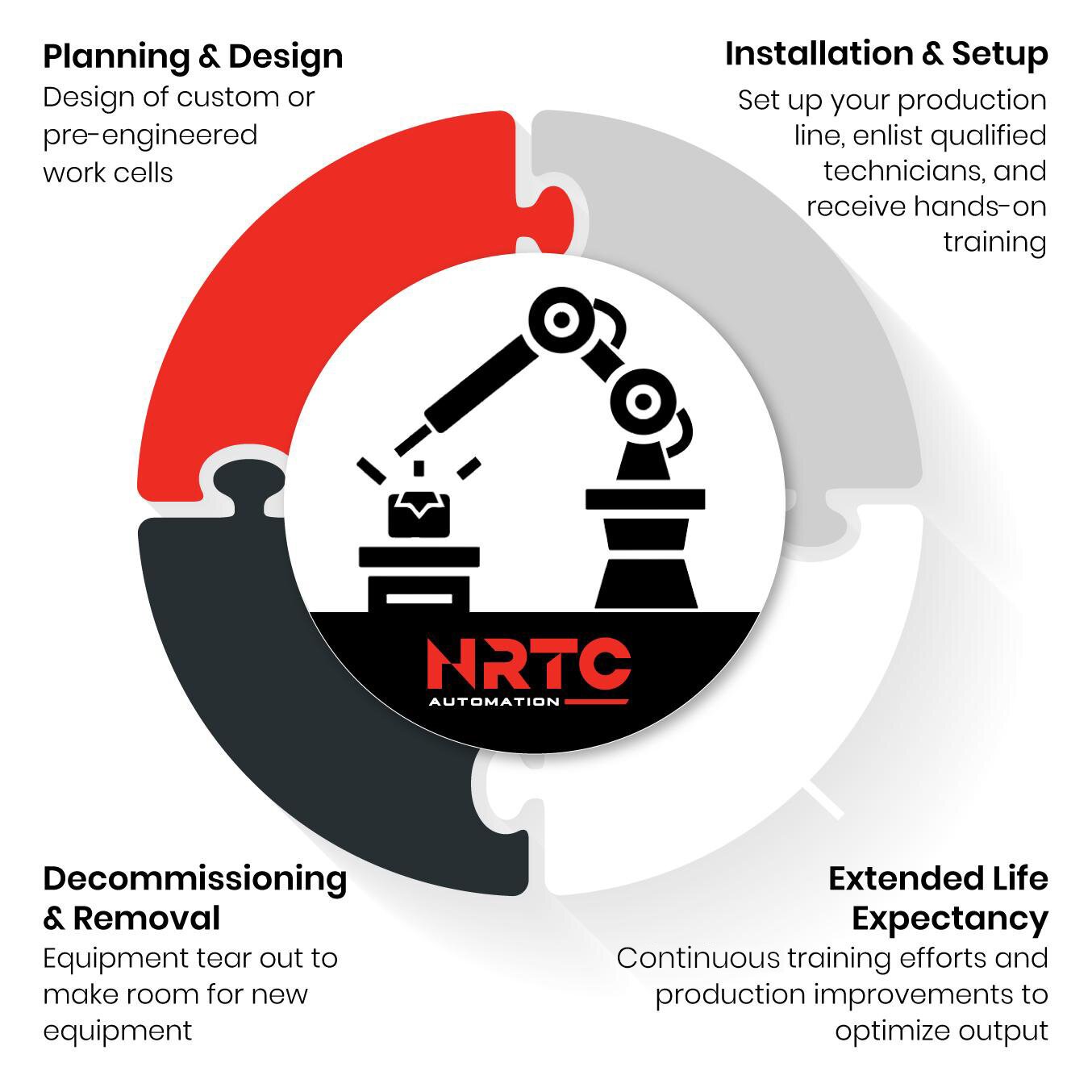

NRTC Automation aims to be your full-service automation partner. The NRTC Lifecycle means we’ll help you from the ground up to build your automated production line, assist with troubleshooting, hiring, and training, and tear it out when you are ready to move on to your next project.

View our graphic to visualize how NRTC can help you from start to finish.

Planning and Design is the foundation of a solid manufacturing process. This phase starts when we help you design and build your custom robotic work cell. Whether you’re looking to install assembly, arc and spot welding, or material handling robotics into your production line, our technicians will work with you to develop a work cell implementation strategy that meets your demands. By scheduling a free consultation with us, you’ll start on the path to more productive manufacturing.

Installation and Setup provides comprehensive production support. We’ll scout and hire qualified technicians for your now-running automated line, as well as offer robotics training to your employees for well-rounded, educated staff. We create personalized training plans for your company so your employees get exactly the training they need.

During the Extended Life Expectancy phase, NRTC Automation offers services that will keep your equipment operating smoothly. Send your equipment to us for repairs, refurbishment, and troubleshooting to ensure that you’ll meet your production goals every quarter. We work with popular brand name robots and equipment like KUKA, Siemens, and ATI to minimize downtime on your warehouse floor.

Decommissioning and Removal will allow you to grow your company on your timeline. We’ll buy your assets and recycle the rest, leaving you with a broom-ready facility for your next project. With an experienced project manager and a team dedicated to your project, you’ll be impressed with how efficiently and effectively we clean out your facility.

Finally, as your long-term automation partner, we’ll start the cycle again to improve your production processes for the next step in your company’s growth.

What industries can benefit from NRTC’s services?

NRTC Automation works with manufacturers of every industry. From plastics to aerospace to automotive, we have the solutions you need to rise above the competition.

How do I get started?

Visit NRTC Automation’s website! You can schedule a free consultation with us. After discussing your current needs, as well as your vision for the future, we’ll create the best automation plan for your company.

Alternatively, if you know what you need, you can submit a form on any of our service offering pages. Our friendly customer service will get back to you within one business day to discuss your options.

BECOME AN NRTC AUTOMATION PARTNER TODAY

NRTC Automation is a trusted partner providing comprehensive industrial automation and manufacturing services. After delivering our services to top automobile manufacturers across the world for more than a decade, NRTC Automation is the destination for tear out services and robotic solutions.

Visit us today on our website to schedule a free consultation.

Meet Sean Burke!

Sean Burke is the General Manager of Automation at NRTC. We interviewed him for our Employee Spotlight feature to learn more about his typical workday and favorite hobbies outside of work.

Sean Burke is the General Manager of Automation at NRTC. We interviewed him for our Employee Spotlight feature to learn more about his typical workday and favorite hobbies outside of work.

After wearing many hats in different companies, Sean is a great fit to manage NRTC’s Automation Services.

Learn more about Sean and his work with NRTC Automation, as well as some fun facts, below!

Sean Burke, General Manager of Automation at NRTC

Background

Sean has diverse experience in automation and engineering, allowing him to run our Automation Services with confidence.

He started with Ford Motor Company in Chicago as a facilities engineer, working on plant layouts, new line installation drawings, and more. He was then promoted to a project management position that allowed him to launch programs and a press, as well as manage programs on the warehouse floor.

He then moved on to Woodhaven Stamping in Michigan to work as a material handling engineer, all while working on packaging, line layout, storage, parts, and forklift management. He transitioned into management at Woodhaven, continuing his work in large facilities: 2.5 million square feet, to be exact!

Sean spent a few years in South Carolina as a material planning and logistics manager before working with Magna. He says that his work varied widely at Magna, ranging from launching programs and assembly to material planning and logistics management, as well as decommissioning.

Before moving to Alabama to launch a Mercedes program as an assembly operations manager, Sean ended his work in South Carolina in a sales role, revamping the aftermarket parts processes for improved coordination.

Regarding the Mercedes program, Sean says, “It was an extremely intense launch, one of the tightest-tolerance bodies that have ever been launched by an automotive company. It was two-and-a-half years that went by very quickly. After that ended, I thought, okay, what's next? And it wound up being an opportunity to join NRTC and iGAM.”

Working with NRTC

Clearly, Sean is a great fit for the role of General Manager of Automation at NRTC. He started with NRTC in November, and he puts in long days to ensure that every customer is cared for up to NRTC’s standards.

Sean mostly works in the Fleming Road warehouse, but he also offers support to the Carson Road warehouse when needed.

A typical day for Sean looks like a 5:30 wake-up, getting his kids ready and hopping on the road to the plant. Before hitting the floor, he’ll check his emails. His mornings always include a “morning brainstorm,” in which Sean walks the warehouse floor to determine where the team is at, what they are doing at the moment, and what they can do better.

He then ensures that the team’s plans are prepared for the day, supporting them with any roadblocks they may have for a more efficient workflow.

Once everyone is set for the day, Sean jumps into his own projects to plan for the weeks and even months ahead to make sure NRTC is going where we need to be. He’ll also set up meetings with other departments for full integration across NRTC’s services.

After a full day of work, Sean stays after the team finishes to walk around the warehouse for one last checkup around 6:00 pm.

From Sean’s perspective, NRTC’s Automation Services excel beyond the competition because of our flexibility and dedication to the customer: “Whatever the customer needs a solution for, we try to provide that. We want to build relationships with our customers; wherever they need help, and we can help them, that’s what we try to do.”

Favorite projects

Sean may be a bit biased, but his favorite project has been working with NRTC to get the new warehouse up and running. He says, “Being able to do it like it’s a blank sheet of paper is really neat. It’s all about getting all the ideas on the table and watching them become a reality on the floor and the excitement that the guys and gals have for where we're heading.”

In terms of past projects, a memorable one for Sean is the automated guided vehicle systems project with Ford. He was able to take the vehicles into the pressroom, which, Sean says, had never been done before. It had taken four years to implement the plan, making it one of the most impressive projects Sean has completed.

Fun facts

What is Sean like outside of the warehouse?

Sean is a dedicated husband and father to four boys, spending his time outside NRTC at home and at school sports events.

He is also a keen fisherman. Sean says the most exciting catch he’s made was a nine-and-a-half-foot tiger shark in Jupiter, Florida. According to a local fisherman that Sean was with, the odds to catch that large of a tiger shark in that area were so low, it should have been impossible!

Sean has another secret: when he was in college, he ranked in the top 50 in the country in billiards. He played against Jeanette Lee, a professional billiards player, in New York City (for fun, he says). Sean continues to play every now and then to keep his skills sharp.

Sean provides top-level services for our customers

As you can see, Sean is an appreciated member of the NRTC team. With his guidance and expertise, we can serve our customers with quality services to meet their needs.

If you are looking for automation services, then work with Sean and the team by visiting the Automation page here.

GET THE AUTOMATION SERVICES YOU NEED AT NRTC

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with NRTC today to learn more.

How to Start 2021 with a More Efficient Production Line

With a few changes, manufacturers can remain competitive in 2021 by improving production efficiency.

With a few changes, manufacturers can remain competitive in 2021 by improving production efficiency.

2020 has been a trial for manufacturers around the globe. The COVID-19 pandemic has changed the way we interact and perform in business, and the industry has experienced ups and downs in production.

The New Year can be a promising arrival of growth, but only if manufacturers approach it correctly.

Efficiency is one way to stay competitive in 2021. Learn how to cut waste, improve customer relations, and increase revenue with your production line below.

How to create a more efficient production line

What is slowing down your production?

There could be several reasons why you aren’t reaching peak production efficiency. Some common causes of slow production include:

Not analyzing data and making necessary changes

Turning off production when it can continue to run

Not automating tasks that are monotonous and require high precision

Inadequate labor

Equipment that needs to be repaired, reconditioned, or replaced

Keeping manufacturing processes in-house that can be outsourced

Manufacturing requires constant management and optimization in order to maintain lean, efficient processes.

Benefits of improving production efficiency

There are clearly many benefits to improving production efficiency. When you have an efficient production line, you can:

Improved product quality: Using automation will improve product quality. With high precision and repeatability, industrial robots and equipment can produce better products at a faster rate than human labor. Your employees can move into roles such as operations and customer service, where their creativity and personalities can be utilized.

Reduce operational costs: Cutting inefficiency will reduce operational costs. For example, reducing the amount of waste that is produced during operations will save on material costs. Also, you can cut energy usage by eliminating unnecessary processes during production and reduce your energy bill.

Improve lead time: A faster and more efficient production line will reduce lead time, getting your product to your customers sooner. This means you can fulfill more orders with an efficient production line.

Improve customer satisfaction: Customers that receive high-quality products in a short amount of time will be happier than customers who must wait for products that are susceptible to human error. They will be more likely to come back to your company in the future.

Increase revenue: More orders due to improved lead time, lower operational costs, and happy return customers will inevitably increase your revenue year after year.

Are you interested in learning how to increase production efficiency? Read the four ways you can optimize your manufacturing processes and how NRTC Automation can help below.

4 ways to increase efficiency in your production line

1. AUTOMATE

Implementing industrial automation into your business is the most effective way to improve production efficiency.

One way of doing this is with an all-in-one flexible robotic work cell. If you are new to automation, this is an easy way to automate your production line without having to source, purchase, and engineer the equipment by yourself.

NRTC Automation can build custom work cells that meet the needs of your company. Our customers have increased capacity and throughput by over 200% simply by adding work cells to their manufacturing process.

Learn more about NRTC’s Automation Services on our website.

2. TRAIN YOUR EMPLOYEES

Trained employees are not only more knowledgeable about their work tasks, but they are more productive because they have increased job confidence and satisfaction.

If you want to train your employees in robotics, consider working with NRTC Automation’s Robotic Training Services. We’ll personalize the training program for your business. With our training, your employees will be able to perform basic programming to advanced diagnostics.

3. OUTSOURCE YOUR PARTS MANUFACTURING

If you manufacture parts under your roof, but it isn’t your main focus, you may benefit from outsourcing your parts manufacturing.

These benefits include:

Lower labor costs

Reduced overhead

Increased focus on the main objective

Increased ability to meet demand

NRTC Automation can take on your parts manufacturing. We service multiple industries in manufacturing and will build a custom work cell in our facility solely for your project. Schedule a free consultation with us to learn more about how we can manufacture your parts.

4. HIRE ON-SITE TECHNICIANS

Last but not least, having an on-site technician can save your production line in an emergency. When equipment breaks down and needs to be repaired, you are spending hundreds of thousands of dollars in unplanned downtime.

Rather than trying to find a technician to service your equipment, you can have one on-site to handle breakdowns as they happen.

Are you looking for an experienced robotics technician but can’t seem to find the right fit? Then try out NRTC’s Engineering Services. We’ll find, interview, and hire qualified professionals for your business. Contact us to learn more and find the right team to get the job done.

Stay competitive in 2021 with optimized production

Using lean manufacturing methodology is the key to staying competitive in 2021. Reducing costs and improving customer relationships will increase your revenue and allow your business to continue to grow.

Try out NRTC Automation’s services listed above to optimize your production line today.

WORK WITH NRTC AUTOMATION TO IMPROVE YOUR MANUFACTURING PROCESSES

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers. From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace.

With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us to create an automation plan that suits the needs of your company.

Meet LaVern Mast!

As NRTC Automation’s Director of Decommissioning, LaVern Mast helps companies move onto the next project while meeting tight deadlines.

As NRTC Automation’s Director of Decommissioning, LaVern Mast helps companies move onto the next project while meeting tight deadlines.

At NRTC Automation, we are dedicated to providing the best for our customers. Our Decommissioning and Tear Out Services stand out because of our commitment to safety, timeliness, and making a return on equipment value.

LaVern Mast is the Director of Decommissioning at NRTC Automation since September 2019. With years of experience in transportation, industrial equipment, and operations, LaVern offers our customers the professional and timely services they need to move onto their next project.

Learn more about LaVern and his work with NRTC Automation below!

LaVern Mast: Director of NRTC Automation Decommissioning Services

Background

LaVern Mast, also known as Vern, has years of experience in transportation, equipment sales, and operations.

Vern spent five years specializing in heavy equipment hauling in the transportation industry. After that, he co-owned and managed equipment rentals and sales in North Florida for three years.

Prior to joining NRTC Automation, Vern worked as the Regional Operations Manager at IronPlanet and subsequently the Director of Government Services Operations at Ritchie Bros & IronPlanet Inc. for a combined 11 years.

Vern’s experience with NRTC Automation

In September 2019, Vern joined NRTC Automation as the Director of Decommissioning.

In his role as Director, Vern oversees the decommissioning and tear out jobs. He delivers quotes by pulling information from the company and the project, including the equipment and its worth. The quote is then based on the timeline that the customer requests.

Vern’s other responsibilities as Director include:

Identifying and choosing the right teams for each decommissioning job from NRTC staff or subcontractors

Managing cost budgets for each decommissioning job

Assisting the sales team with new business development

For large decommissioning projects, Vern will attend the job to support the team and ensure a smooth tear out process.

Passing decommissioning jobs with flying colors

Not only does Vern excel in managing NRTC Automation’s decommissioning projects, but he is also an avid pilot. Vern has been flying for 16 years, and he is IFR rated, which enables him to fly in various weathers.

Vern says that he takes pleasure in flying as his method of travel to decommissioning job sites. He also enjoys flying as a hobby, as he finds it to be stress-relieving.

A multi-talented man, Vern makes an excellent addition to NRTC Automation’s team.

Working in decommissioning

Decommissioning a facility of any size requires a dedicated and focused team. That’s why NRTC Automation trusts Vern with his years of experience in transportation and industrial equipment to run even our most complex tear out projects.

NRTC Automation has trained and experienced project managers ready and able to do the job. When Vern is selecting a project manager to lead a job, he chooses a professional with a background in management, including both people and projects. NRTC’s decommissioning project managers are also well-versed in industrial equipment and automation to perform the job well.

As a decommissioning team member, the perfect candidate for a project would have electrical, mechanical, and demolition experience. However, NRTC Automation can train from the ground up. Our internal team has the know-how and experience to provide our customers with smooth and quick tear out.

For our team members, safety is a priority. The most dangerous part of the job is successfully disconnecting the 480-volt power sources, from the industrial machines. The decommissioning team must be trained in OSHA safety standards to prevent accidents. Our teams also ensure that all equipment is disconnected before performing any work, as well as using lockout/tagout (LOTO) procedures consistently.

What differentiates NRTC Automation from the rest?

1. SAFETY

As mentioned, safety is NRTC Automation’s priority. We have an impeccable safety record which is aided by:

Our team’s training in safety standards as mandated by OSHA

Our branded high-visibility safety gear

The safety perimeters and signage that we set up for every project

The detailed plan we create for each project for a smooth tear out process

2. TIMELINESS

Plus, NRTC Automation completes decommissioning projects based on customers’ timelines. That means if you have a due date to move onto your next project or relocate to a new facility, NRTC Automation will help you meet it.

To show you how committed we are to meeting your deadline, NRTC Automation has met the deadline or finished ahead of schedule for 100% of the projects we’ve completed.

3. VALUE

Our competitors can’t match the value we provide for our customers.

Our tried and true process starts with providing our customers with a 3D scan of the facility to prepare the best tear out plan.

NRTC Automation will evaluate your equipment to determine what can be repurposed and what will be scrapped. The repurposed equipment still has value, which can become a return on your original investment.

We assign one of our project managers and a team dedicated solely to your tear out. Then, once the decommissioning process is complete, you’ll have a broom-ready warehouse prepared for your next move.

No matter the reason for a tear out—be it for relocation, an updated assembly line, a new project, or whatever else—NRTC Automation will decommission your facility by your deadline.

Interested in decommissioning with NRTC Automation?

Schedule a free consultation! We will provide you with a quote so you can clear out the production floor on your timeline. Free up space and move onto your next project with NRTC Automation.

CONTACT NRTC AUTOMATION TODAY.

NRTC Automation is a trusted partner providing comprehensive industrial automation and manufacturing services. After delivering our services to top automobile manufacturers across the world for more than a decade, NRTC Automation is the destination for tear out services and robotic solutions.

Visit us at www.nrtcautomation.com.

NRTC is Working Toward the ISO 9001 Certification

We value customer satisfaction, so NRTC Automation is working toward a certification in ISO 9001 to show the quality and consistency of our services.

We value customer satisfaction, so NRTC Automation is working toward a certification in ISO 9001 to show the quality and consistency of our services.

Without standards, determining the quality of a product or service would be difficult, especially while researching companies.

In manufacturing and technology, it’s even more difficult. The International Organization for Standardization filled the gap to provide companies with certifications to show their customers that they are trustworthy and reliable.

NRTC Automation is in the process of receiving the ISO 9001: 2015 Revision Certification for Service Parts Manufacturing. We want our customers to know that we value their trust and satisfaction, and this standard will prove the high quality of our services.

Learn more about the ISO 9001: 2015 Revision below.

ISO 9001: 2015 Revision Certification

Who is the ISO?

The ISO 9001 Standard is set by the International Organization for Standardization, or ISO. They were founded in 1947 and set standards for almost all sections of manufacturing and technology. As of 2020, they have implemented over 23,000 standards.

Fun fact: the organization set its acronym as ISO since the acronyms would change in different languages. According to their website, ISO is derived from the Greek word isos, meaning “equal.”

What is the ISO 9001 Standard?

The ISO 9001: 2015 Revision is a standard set to help organizations show their customers that they provide quality, reliable, and consistent products and services.

On the ISO website, the ISO Secretary-General Kevin McKinley says that “ISO 9001 allows organizations to adapt to a changing world. It enhances an organization’s ability to satisfy its customers and provides a coherent foundation for growth and sustained success.”

The ISO 9001 standard has experienced continual improvement over several decades, with 2015 being the latest revision to the standard. In the 2015 revision, ISO shifted its focus onto performance as opposed to strict documentation rules with an emphasis on risk management.

The “Plan-Do-Check-Act cycle” in the 2015 revision provides a guideline for participating companies to prepare and defend their businesses from risks.

How will NRTC qualify for this standard?

NRTC Automation is working toward adding this certification by early- to mid-2021.

There are several audits that occur during the certification process:

There is a pre-assessment audit performed by a third-party auditor.

After that, in the Stage 1 Audit, companies are expected to improve their processes from the pre-assessment.

There are usually two audits after the pre-assessment, which is then followed by the Registration Audit.

All these audits ensure that companies are not only doing what they should be doing in their industries, but that they are also improving upon their processes to better serve their customers.

NRTC Automation will qualify for ISO 9001: 2015 Revision after we pass the initial audits and the final Registration Audit. With our commitment to success and our dedication to providing the best service to our customers, we expect to receive our certification with confidence.

How does this certification benefit our customers?

By achieving a certification in the ISO 9001: 2015 Revision standard in our Service Parts Manufacturing, our customers can feel a sense of security knowing that we meet international requirements for documentation, risk management, and improvement.

We show full transparency in our processes, so our customers know that we are providing them with the quality-assured manufactured service parts that we promise. We have both internal audits and external audits because we take your satisfaction seriously.

NRTC Automation intends to extend this certification to the rest of our automation services in the near future. Whether you need us to decommission your factory or want to receive industrial robot refurbishing services, we want you to feel that you have placed your company in qualified and reliable hands.

TRUST NRTC AUTOMATION WITH YOUR NEXT PROJECT.

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers. From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace.

With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services. Fill out the form on our website to receive a free consultation and learn how we can help you grow your business.

NRTC Automation is Offering Free Consultation Services

With a free consultation service, you’ll learn how NRTC Automation will tailor our services to help you develop an automated manufacturing business.

With a free consultation service, you’ll learn how NRTC Automation will tailor our services to help you develop an automated manufacturing business.

Growing your business in manufacturing means enhancing your production line with automation. This poses a challenge to manufacturers who aren’t sure what steps to take to integrate industrial automation into their company.

With NRTC Automation as your trusted partner, you can grow with confidence.

We are offering free consultation services so you can find out how we can help you move to the next level in your manufacturing business.

NRTC Automation Free Consultation Services

Who are we?

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

We have over a decade of experience in industrial automation and manufacturing. As a trusted partner of top auto manufacturers around the world, we offer high-quality, timely, and professional automation services for manufacturers of all sizes.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

What can NRTC Automation do for you?

There are few automation problems that NRTC can’t solve. From building your production line to tearing out your facility, we can help you move into the next phase of development, no matter where you’re at.

NRTC Automation offers decommissioning and tear out services for warehouses ranging in size from 5k square feet to 750k square feet. We’ll provide a dedicated project manager and team to your project and get the job done on your timeline.

We also design, build, and engineer custom robotic work cells so you can automate your production line with ease.

If you need service parts manufacturing, we can do that, too! We’ll build a work cell in our facility specifically for your company and ship out service parts to you for as long as you need it.

We also offer robotic training services, industrial robot refurbishing, and tool and fixture storage to cover your automation needs.

Want help automating your company?

Are you having ergonomic, throughput, or quality challenges with your manufacturing operation?

Visit NRTC Automation for a free consultation! We’ll talk through your toughest automation problems and help you take the next step toward growing your business.

From building parts for your business to automating your production line, we can help.

How to Request a Free Consultation

Requesting a consultation is easy. Fill out the form on our website with as much information as you can provide us. Be sure to include video and/or photos, and a thorough description of what you need. We suggest that you provide as much detail as possible so we can prepare the best plan for your company.

Once we receive and review the information, we’ll contact you to set up a time for the free consultation via a Teams, WebEx, or Zoom call. It’s that easy! Come with your list of questions and we’ll be prepared to provide answers.

Note: Due to COVID-19 restrictions, all consultations will be held over phone and video calls.

AUTOMATE YOUR BUSINESS WITH NRTC AUTOMATION TODAY.

NRTC Automation is experienced in helping manufacturing businesses in any industry develop automation in their company. With our comprehensive automation services, we are able to assist in every step of the process as you build your production line.

Schedule your free consultation with NRTC Automation today and secure a more productive and profitable future for your business.