NRTC AUTOMATION BLOG | INDUSTRIAL ROBOTS AND AUTOMATION

How Can You Adapt to Rapidly Changing Industrial Automation?

Manufacturing is changing. Industry 4.0 is advancing manufacturing with limitless opportunities for growth.

If you’ve been paying attention to the news, you’ve probably noticed two trends: COVID-19 and Industry 4.0.

Today, we’re passing up an analysis on the pandemic’s impact on the industry to discuss the Fourth Industrial Revolution. If you are a small- to mid-sized manufacturer, you may feel left behind in all this innovation. Thankfully, NRTC Automation is here to help!

Learn more about the digital revolution and how to keep up below.

Adapting to changes in industrial automation

Shifting from traditional to digital manufacturing

In the last 100 years, manufacturing has made some impressive leaps.

Innovations in the production line have improved productivity drastically, enabling manufacturing to put out more product and reduce waste.

When industrial robots hit the scene in the mid-20th century, the industry changed forever. Now, manufacturers could create uniform products in minimal time with fewer (costly) mistakes.

Today, the digital manufacturing revolution, or Industry 4.0, is revolutionizing the way manufacturers view data and production. With the help of AI and IoT, seeing the intricacies of the manufacturing process is easier than ever before.

What it means for manufacturing

Industry 4.0 is changing the face of manufacturing.

Digital information allows manufacturers and operators to enhance their production lines with limitless data. For example, if productivity drops slightly, an alert from IoT connected devices will notify the operator. Depending on the cause, the operator may choose to tweak the equipment to enhance performance. Better operational efficiency means a greater bottom line for your company and a more competitive stance in your industry.

Plus, digital manufacturing allows machines to communicate with each other, reducing the amount of labor needed from employees on the production line. Your staff can work more fulfilling and engaging jobs rather than working the line, which can be dangerous for their health. Less workers on the line means increased cost savings for you as well: a production line operated by one person saved an average of $120,000 every month.

Prototyping and 3D printing are also improved due to Industry 4.0. Now, because of additive manufacturing, manufacturers can design and create a prototype in a fraction of the time compared to traditional prototyping methods. Product development is sped up, getting your product to your customers sooner.

How to adapt to Industry 4.0

No matter where you are in your journey to automation, we suggest the following to stay up-to-date with the latest developments in digital manufacturing.

INCREASE CYBERSECURITY PRACTICES

Manufacturing is one of the most targeted industries for cyber attacks. With one fell swoop, hackers can destroy your internal systems and leak confidential information.

Can your company withstand a day, or even a week, without power to run your manufacturing facility? If not (and most companies cannot), then you need to strengthen your firewalls and other cybersecurity practices before you become a victim.

Check out our blog post here for ways in which you can protect your company and employees from malicious cyber threats.

ADD SMART DEVICES

Now is the time to invest in IoT.

Adding smart devices to your facility will put you in line with even the biggest competitors in your industry. Using the latest technology in IoT will enhance supply chain management so you can continue to optimize your production line for the best results.

USE YOUR DATA

Finally, use the data that digital manufacturing offers you.

Data is an extremely valuable tool that allows you to shift from a confusing and mismanaged warehouse to an efficient, streamlined production line.

Minimize downtime and increase productivity by making informed decisions on what changes to apply to your production line. The opportunity for improvement is limitless, so take advantage of data to enhance your manufacturing processes.

Start slow and get industrial automation support with NRTC

If you are a small- to mid-sized manufacturer who wants to grow, but you’re new to automation, then you’ve come to the right place.

We will help you meet your production goals and rise above the competition by adopting comprehensive and sustainable automation practices.

NRTC Automation offers full-service solutions to assist you from start to finish:

With NRTC, you can keep up with changes in the industry and improve your business in the process. We work with top auto manufacturers such as Toyota, Mercedes, and Ford, so you know you can trust us. Head over to our site to learn more about our decade of experience in the industry.

Plus, check out our YouTube video below to see more of our warehouse!

VISIT NRTC AUTOMATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us today to get personalized automation strategies for your company.

How to Optimize Automation in Your Facility

Want to make the most out of your industrial robots? Use these five tips to improve productivity, minimize downtime, and increase throughput by optimizing automation in your facility.

Want to make the most out of your industrial robots? Use these five tips to improve productivity, minimize downtime, and increase throughput by optimizing automation in your facility.

Adding automation is only one step to success when growing your manufacturing company.

Even before adding industrial robots, such as KUKA robots or FANUC robots, as well as other automation equipment to your production line, there are ways to improve production so that once you add automation, it works as intended.

Learn more about how to optimize industrial robots and equipment in your production line below!

How to optimize automation in your facility

Implement these simple tips into your production line to get the most out of your industrial robots.

1. Create clear and concise end goals.

Knowing the end goal in your intention to automate is necessary to have a functional robotic production line. Are you automating just to stay on par with similar companies in your industry? If so, that will lead to a lack of foresight needed to know what needs to be automated (and what doesn’t!).

These are some questions that relate to clear, actionable goals that necessitate automating:

Do you want to cut down on time and reduce production waste?

Are there tasks in your business that are highly repetitive and would benefit by adding a robot, thus reducing human error?

Do you want to standardize your production process?

By taking the time to consider why you want to automate in the first place, you can understand what parts of the production process needed to be automated and how it will integrate into your workplace.

2. Add valuable staff to manage the production line.

Humans are integral to automation. When we work with automation, we can learn what is or isn’t working and improve our processes.

Automation is excellent for businesses because it produces data on your manufacturing process. You can find out where energy is being wasted, which tasks are time dumps, and more.

Have an employee or a team that checks on the status of your automation and data. They can come up with ideas that can save you time and money as your company grows.

3. Check for any missing components in your production line.

You don’t need a production line solely worked by robots in order to have a successful automated business. You do need a production line that is airtight and doesn’t have any gaps that may cause downtime or buildup.

Streamlining is the name of the business. When you automate, you should have a smooth production flow that has a step for every part of the process. Take the time to observe your production line in action and note what could be improved; ideally, look at the data from reason #2 and find out where you can make adjustments.

4. Get educated on industrial robotics and automation.

Automation is not limited to robots. When you automate your company, there are servo drives, pedestals, end-of-arm-tools, circuit breakers and circuit protection, productivity displays, and so many other components to industrial production that you must account for.

Each piece of equipment benefits the production line in a different way. Most of this equipment is necessary for the production line to function properly.

If you want to automate your business successfully, then getting educated on robotics and industrial equipment is a good way to start. Learn about the anatomy of an automated production line, or read more about the connection between servo drives and motors.

Every bit of knowledge will help you make better decisions when adding industrial automation to your manufacturing process.

5. Prioritize company-wide involvement and understanding of automation.

Last but not least, you might be failing at automation if your team doesn’t understand how it works.

When everyone understands the effort to automate and knows how their job relates to the robot in the production room, then automation can become a collaborative effort.

Working together to have a cohesive automated company will not only increase your chances of having a productive and efficient automated line, but it will also boost company morale and improve your work environment.

Bring everyone together for monthly lunches and update the team on the latest automated processes to fully integrate robotics into your company.

Improve your operations today using automation.

As industrial automation becomes more mainstream and technologies advance, the ability to automate your business gets easier. Plus, you have resources like NRTC Automation to help you build and improve your automation process so you can be successful from the beginning.

NRTC AUTOMATION WILL WORK WITH YOU TO AUTOMATE YOUR COMPANY.

Automating your business will allow you to be more efficient, reduce your production waste, and increase your revenue. Work with NRTC Automation, a trusted partner of top auto manufacturers around the world, to automate your company.

NRTC offers turnkey solutions such as building, designing, and engineering customized work cells that will seamlessly fit into your production line. We also train companies in robotics, repair industrial equipment with professional technicians, manufacture service parts, and more.

Schedule a free consultation here to get a personalized automation plan for your company.

Why Everyone is Obsessed with Industrial Robots

Automation is all over the news. NRTC discusses the hype and how you can jump into automation with us.

Automation is all over the news. NRTC discusses the hype and how you can jump into automation with us.

Coverage on industrial robots is growing, especially since the start COVID-19, as more industries are adopting automation to cope with new social distancing and hygiene mandates.

Are you curious about the direction automation is taking us? Read more about current predictions and how NRTC Automation can help you join the movement below.

The future of industrial automation

Industrial robots in the news

If you've been on news sites in the past decade, then you’ve seen articles and videos about industrial automation and robotics.

We won’t get into the myths of industrial robots here—we’ve already covered that topic in this blog post—but we are interested in discussing the recent boom in automation that everyone is talking about.

For example, Yaskawa Motoman recently became part of the 500k club, selling half a million robots over the course of the company’s history. FANUC is another robot manufacturer who surpassed the half-million mark.

Clearly, there is a demand for automation. Even though industrial robot sales slumped the past two years due to an economic downturn in 2019 and COVID in 2020, sales are beginning to pick up again.

Industries that use automation

Automation is the key to the future of manufacturing.

Other industries are also using automation to improve productivity, accuracy, and efficiency, such as:

Agriculture: Industrial robots and drones are used to plant, water, pick, and sort crops, reducing lead time from harvest to shipment and assisting with backbreaking jobs in the daily work of agriculture laborers.

Food preparation: Robots are making their way into the kitchen, to the relief of many who don’t love spending hours on meal preparation and cleanup. Check out Flippy the robotic burger flipper for some good old-fashioned robot entertainment.

Military and public safety: Robotic technology such as drones are being used by the military and public safety sectors. For example, with drones, rescue operations are made easier by improved visibility and access to hazardous areas caused by natural disasters.

Healthcare: Surgical robots are not new to the medical field. Doctors use them for increased precision during surgery. Additionally, and especially during COVID-19, robots are used to clean facilities by scrubbing the floor, emitting UV light, and other methods. Other industries, such as manufacturing, are using hygienic robots to maintain COVID-19 cleaning mandates.

As our world becomes increasingly digital, more industries are adopting automation to keep pace with changes in technology and public expectations.

Predictions about automation

For better or for worse, much of the buzz in the news about automation has to do with predictions of the future.

Common questions about automation include:

What industries will robots move into next?

How will businesses change in response to increasing automation?

How will automation affect human labor?

What are the potential security risks of increasing automation?

While some articles develop a doomsday scenario that robots will take over an overwhelming majority of human jobs, others negate that perspective. Industrial robots and other automation will handle repetitive physical labor and number-crunching work, but creative services, management, interpersonal work, and similar jobs will remain in the human realm.

Automation is progressing rapidly, and so are we. Changes in the labor landscape have been occurring for hundreds of years as innovations are made.

In response to advancements in technology, new jobs have been created, such as digital marketers, robot technicians, app developers, data scientists, and more.

Why you should start automating

In the manufacturing industry especially, industrial automation is the key to growth.

Benefits of adding industrial robots and manufacturing equipment to your production line include:

Increased scalability: Automation improves efficiency and minimizes downtime, getting your product to your customer sooner. You’ll be able to meet greater demand by cutting down on wasted time.

Improved workplace safety: As mentioned above, industrial robots take over the dirty, dangerous, and repetitive work that is notorious for causing musculoskeletal injuries.

Enhanced product quality: Robots are more precise, resulting in improved product quality. For example, robotic welders provide a clean and accurate weld every time so you don’t have to worry about unnecessary product recalls.

Adopting automation doesn’t have to be difficult. By using a service like NRTC Automation, you can be well on your way to competitive advancements in productivity and operation efficiency.

How to get started

Are you looking to jump into automation?

NRTC can guide you from start to finish. Our Automation Services will get you on the fast track to start increasing throughput and capacity in your facility. We’ll work with you to design, build, and engineer a custom work cell for your production needs.

We work with top auto manufacturers like Toyota, Ford, and BMW, as well as small- to mid-sized manufacturers looking to grow their businesses. With over a decade of experience, and with our professional engineers and technicians, we provide some of the best automation solutions in the industry.

Plus, we offer financing to make automation affordable for manufacturers of any size. Get ahead of the competition and start automating with NRTC today.

WORK WITH NRTC AUTOMATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation here and we’ll develop an automation plan specific to your company’s needs.

SPECIAL EVENT: No Reserve Harley-Davidson Auction – Only 1 Day Left!

Limited time only! NRTC Automation is hosting an auction through Aucto for Harley-Davidson industrial equipment and parts.

Limited time only! NRTC Automation is hosting an auction through Aucto for Harley-Davidson industrial equipment and parts.

There’s only one day left to bid! This is a NO RESERVE auction. Bid on equipment from a closed Harley-Davidson plant at low prices for your facility.

Bid Now on Harley-Davidson Equipment

Shop online for dock ramps, petroleum tanks, transformers, compactors, and more. Get the equipment you need at an affordable price from one of the most popular motorcycle brands around the world.

Now is your chance to bid! Head over to Aucto to name your price.

NRTC IS YOUR LONG-TERM AUTOMATION PARTNER.

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all our customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with NRTC Automation today.

Spring Ahead in Production: Outsource Parts Manufacturing

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

Get moving on your goals this spring by outsourcing parts manufacturing with NRTC Automation.

The saying “It takes a village” holds truth: growth in any form requires extensive support.

Manufacturing is no different. You don’t have to handle all the production under your own roof; by delegating tasks outside of your company, you can focus on what’s important.

Learn more about the benefits of outsourcing parts manufacturing and working with NRTC below!

Outsourcing your parts manufacturing

Your warehouse can only handle so much

From storing parts and materials to running equipment to shipping, there’s a lot going on in a manufacturing warehouse.

You might be reaching the limits of your capabilities depending on the size of your warehouse and the phase of your company’s growth.

Thankfully, that doesn’t mean you have to move into a bigger facility before you’re ready. By outsourcing parts production, you can continue to scale your company according to demand without making sacrifices.

Outsource parts production

Outsourcing is a simple solution to transitory phases in growth, and it’s useful for small and large companies alike. In fact, 39 percent of small companies outsource at least one of their business procedures to save money and resources.

No matter what industry you’re in, outsourcing parts production will help you focus on important manufacturing goals.

NRTC Automation can help. With our Service Parts Manufacturing, you can trust us to create the parts you need with a custom-built work cell made specifically for your company's needs.

We can manufacture parts for any industry: from plastics to aerospace to automotive, we have the tools to supply parts for you.

Benefits of outsourcing your parts manufacturing

Why should you consider outsourcing your parts manufacturing? Well, the benefits extend across your entire company, including:

Increased space: Without the extra materials, equipment, tools, and personnel to produce parts, you’ll have more warehouse space.

Cost savings: Save money by delegating parts production to another company rather than moving to a larger, more expensive facility before you are ready. Additionally, save on energy, labor, and equipment costs associated with parts production.

Enhanced focus: Remove the extraneous production tasks (a common suggestion in lean manufacturing) so your focus won’t be spread thin. Then, you can dedicate time and resources to your main manufacturing goals.

Improved efficiency: By shifting your focus to the important goals, your facility will be more efficient rather than wasting valuable uptime on parts.

Increased scalability: Meet greater demand with more warehouse space and efficient processes to improve your bottom line.

Finding a partner to outsource your parts production will give your company the space it needs to grow. If you want to become competitive in your industry, work with NRTC Automation today.

Prototyping capabilities

On top of parts production, NRTC Automation offers prototyping services. Innovate product design while saving time, money, and manufacturing resources.

Let us bring your ideas to fruition. We’ll work closely with you and create a custom work cell in our warehouse to develop your designs. With a decade of experience, you can trust us to help you transform your business with new, competitive products.

NRTC Automation can manufacture prototypes for as long as you need. Simply contact us or give us a call at (877) 228-2161. We can discuss your prototyping design and turn your vision into a reality.

Spring ahead in production

As you can see, outsourcing parts production and prototyping will not only give you warehouse space and increase efficiency, but it’ll also give you the focus you need to grow your company.

Are you ready to move to the next stage of growth? Decommission your current facility with NRTC to get it into broom-ready condition so you can move with ease.

We’ll assign an experienced project manager and team dedicated solely to your project to finish it on your clock. NRTC has a 100 percent success rate of meeting our partners’ timelines, including top auto manufacturers like Toyota, Mercedes, and BMW. Work with us today to grow your business.

SCHEDULE A FREE CONSULTATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website to schedule a free consultation with us, no strings attached.

What is the NRTC Lifecycle?

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

You can trust that, with NRTC Automation, you’ll be supported from the start of your automation journey to the next stages of growth.

NRTC Automation prides itself on providing our customers with services that meet any automation need they might have.

From decommissioning to industrial robot refurbishing to custom work cells, NRTC is your ideal partner for growth in the manufacturing industry.

Learn more about the NRTC Lifecycle and how you can become an NRTC partner below.

Join the NRTC Lifecycle

Who is NRTC Automation?

NRTC Automation was founded over a decade ago, providing decommissioning and automation services for small to large manufacturing facilities.

We are trusted by the world’s top automotive manufacturers, and we continue to preserve our reputation with personalized and deliberate services for our customers.

We are best known for our Decommissioning and Tear Out Services. With a team dedicated to the customer’s project, a project manager that guides the customer every step of the tear out, and our ability to meet deadlines according to the customer’s needs, NRTC Automation sustains our role as leader in providing decommissioning services worldwide.

On top of world-class decommissioning and tear outs, NRTC Automation also offers Service Parts Manufacturing Services and Automation Services.

We can manufacture service parts for your company in our warehouse with a custom-built work cell specific to your design needs. Also, we offer prototyping so our customers can focus on manufacturing while we perfect their product.

NRTC's Automation Services provide turnkey automation solutions for any production line. We’ll design, build, and engineer a custom work cell for you with affordable refurbished equipment. Our customers have reported an increase in throughput and capacity by over 200 percent just by adding our custom work cells to their facility.

Other automation services for a well-rounded manufacturing company include:

Our comprehensive industrial and automation services give manufacturers the ability to stay on top of their production needs and maintain productivity levels.

What is the NRTC Lifecycle?

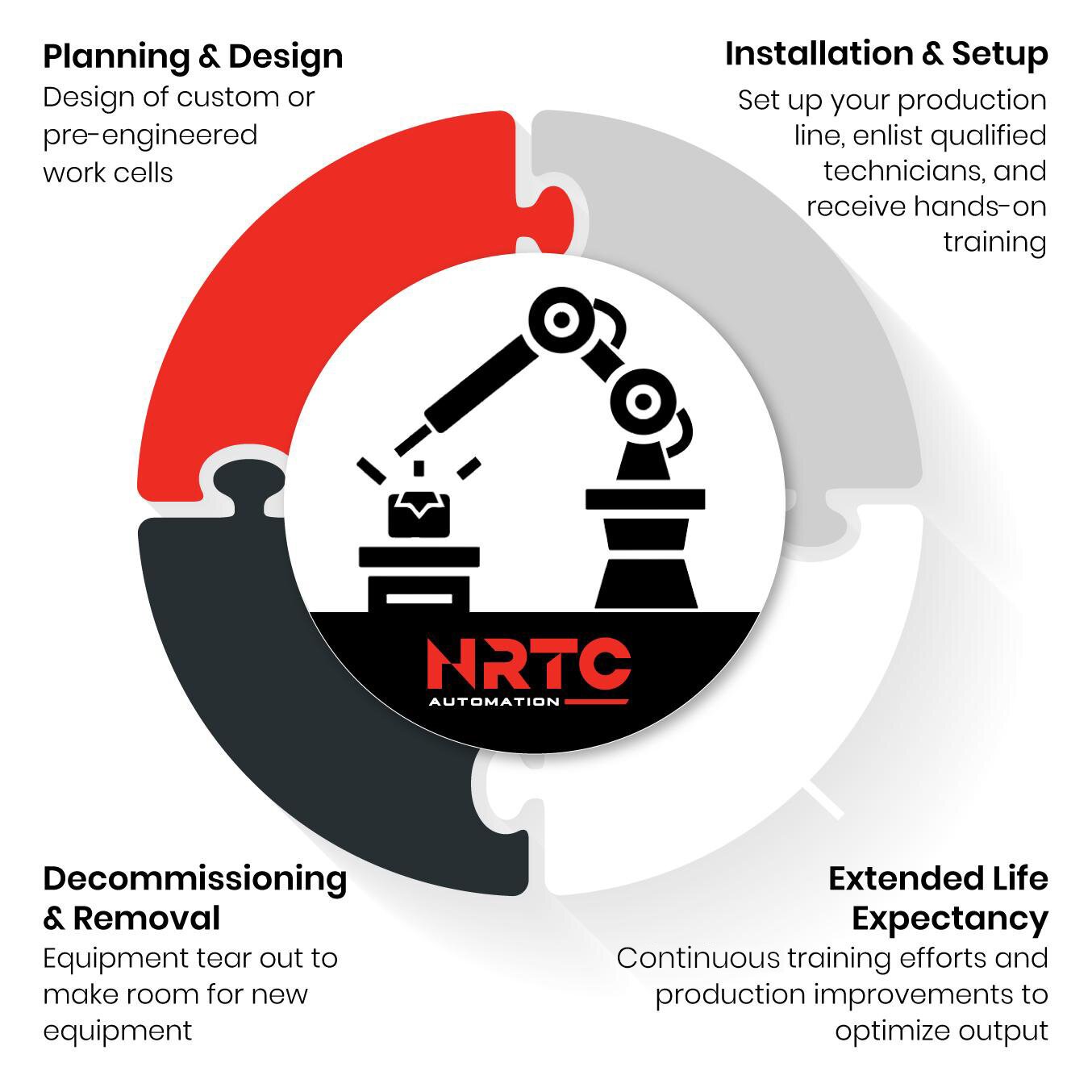

NRTC Automation aims to be your full-service automation partner. The NRTC Lifecycle means we’ll help you from the ground up to build your automated production line, assist with troubleshooting, hiring, and training, and tear it out when you are ready to move on to your next project.

View our graphic to visualize how NRTC can help you from start to finish.

Planning and Design is the foundation of a solid manufacturing process. This phase starts when we help you design and build your custom robotic work cell. Whether you’re looking to install assembly, arc and spot welding, or material handling robotics into your production line, our technicians will work with you to develop a work cell implementation strategy that meets your demands. By scheduling a free consultation with us, you’ll start on the path to more productive manufacturing.

Installation and Setup provides comprehensive production support. We’ll scout and hire qualified technicians for your now-running automated line, as well as offer robotics training to your employees for well-rounded, educated staff. We create personalized training plans for your company so your employees get exactly the training they need.

During the Extended Life Expectancy phase, NRTC Automation offers services that will keep your equipment operating smoothly. Send your equipment to us for repairs, refurbishment, and troubleshooting to ensure that you’ll meet your production goals every quarter. We work with popular brand name robots and equipment like KUKA, Siemens, and ATI to minimize downtime on your warehouse floor.

Decommissioning and Removal will allow you to grow your company on your timeline. We’ll buy your assets and recycle the rest, leaving you with a broom-ready facility for your next project. With an experienced project manager and a team dedicated to your project, you’ll be impressed with how efficiently and effectively we clean out your facility.

Finally, as your long-term automation partner, we’ll start the cycle again to improve your production processes for the next step in your company’s growth.

What industries can benefit from NRTC’s services?

NRTC Automation works with manufacturers of every industry. From plastics to aerospace to automotive, we have the solutions you need to rise above the competition.

How do I get started?

Visit NRTC Automation’s website! You can schedule a free consultation with us. After discussing your current needs, as well as your vision for the future, we’ll create the best automation plan for your company.

Alternatively, if you know what you need, you can submit a form on any of our service offering pages. Our friendly customer service will get back to you within one business day to discuss your options.

BECOME AN NRTC AUTOMATION PARTNER TODAY

NRTC Automation is a trusted partner providing comprehensive industrial automation and manufacturing services. After delivering our services to top automobile manufacturers across the world for more than a decade, NRTC Automation is the destination for tear out services and robotic solutions.

Visit us today on our website to schedule a free consultation.

Meet Sean Burke!

Sean Burke is the General Manager of Automation at NRTC. We interviewed him for our Employee Spotlight feature to learn more about his typical workday and favorite hobbies outside of work.

Sean Burke is the General Manager of Automation at NRTC. We interviewed him for our Employee Spotlight feature to learn more about his typical workday and favorite hobbies outside of work.

After wearing many hats in different companies, Sean is a great fit to manage NRTC’s Automation Services.

Learn more about Sean and his work with NRTC Automation, as well as some fun facts, below!

Sean Burke, General Manager of Automation at NRTC

Background

Sean has diverse experience in automation and engineering, allowing him to run our Automation Services with confidence.

He started with Ford Motor Company in Chicago as a facilities engineer, working on plant layouts, new line installation drawings, and more. He was then promoted to a project management position that allowed him to launch programs and a press, as well as manage programs on the warehouse floor.

He then moved on to Woodhaven Stamping in Michigan to work as a material handling engineer, all while working on packaging, line layout, storage, parts, and forklift management. He transitioned into management at Woodhaven, continuing his work in large facilities: 2.5 million square feet, to be exact!

Sean spent a few years in South Carolina as a material planning and logistics manager before working with Magna. He says that his work varied widely at Magna, ranging from launching programs and assembly to material planning and logistics management, as well as decommissioning.

Before moving to Alabama to launch a Mercedes program as an assembly operations manager, Sean ended his work in South Carolina in a sales role, revamping the aftermarket parts processes for improved coordination.

Regarding the Mercedes program, Sean says, “It was an extremely intense launch, one of the tightest-tolerance bodies that have ever been launched by an automotive company. It was two-and-a-half years that went by very quickly. After that ended, I thought, okay, what's next? And it wound up being an opportunity to join NRTC and iGAM.”

Working with NRTC

Clearly, Sean is a great fit for the role of General Manager of Automation at NRTC. He started with NRTC in November, and he puts in long days to ensure that every customer is cared for up to NRTC’s standards.

Sean mostly works in the Fleming Road warehouse, but he also offers support to the Carson Road warehouse when needed.

A typical day for Sean looks like a 5:30 wake-up, getting his kids ready and hopping on the road to the plant. Before hitting the floor, he’ll check his emails. His mornings always include a “morning brainstorm,” in which Sean walks the warehouse floor to determine where the team is at, what they are doing at the moment, and what they can do better.

He then ensures that the team’s plans are prepared for the day, supporting them with any roadblocks they may have for a more efficient workflow.

Once everyone is set for the day, Sean jumps into his own projects to plan for the weeks and even months ahead to make sure NRTC is going where we need to be. He’ll also set up meetings with other departments for full integration across NRTC’s services.

After a full day of work, Sean stays after the team finishes to walk around the warehouse for one last checkup around 6:00 pm.

From Sean’s perspective, NRTC’s Automation Services excel beyond the competition because of our flexibility and dedication to the customer: “Whatever the customer needs a solution for, we try to provide that. We want to build relationships with our customers; wherever they need help, and we can help them, that’s what we try to do.”

Favorite projects

Sean may be a bit biased, but his favorite project has been working with NRTC to get the new warehouse up and running. He says, “Being able to do it like it’s a blank sheet of paper is really neat. It’s all about getting all the ideas on the table and watching them become a reality on the floor and the excitement that the guys and gals have for where we're heading.”

In terms of past projects, a memorable one for Sean is the automated guided vehicle systems project with Ford. He was able to take the vehicles into the pressroom, which, Sean says, had never been done before. It had taken four years to implement the plan, making it one of the most impressive projects Sean has completed.

Fun facts

What is Sean like outside of the warehouse?

Sean is a dedicated husband and father to four boys, spending his time outside NRTC at home and at school sports events.

He is also a keen fisherman. Sean says the most exciting catch he’s made was a nine-and-a-half-foot tiger shark in Jupiter, Florida. According to a local fisherman that Sean was with, the odds to catch that large of a tiger shark in that area were so low, it should have been impossible!

Sean has another secret: when he was in college, he ranked in the top 50 in the country in billiards. He played against Jeanette Lee, a professional billiards player, in New York City (for fun, he says). Sean continues to play every now and then to keep his skills sharp.

Sean provides top-level services for our customers

As you can see, Sean is an appreciated member of the NRTC team. With his guidance and expertise, we can serve our customers with quality services to meet their needs.

If you are looking for automation services, then work with Sean and the team by visiting the Automation page here.

GET THE AUTOMATION SERVICES YOU NEED AT NRTC

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with NRTC today to learn more.

NRTC Honors Our Women Employees

For Women’s History Month, NRTC is featuring Tosha Hornbuckle and Erica Hooks, two highly valued women employees in our warehouse.

For Women’s History Month, NRTC is featuring Tosha Hornbuckle and Erica Hooks, two highly valued women employees in our warehouse.

March marks Women’s History Month, giving us the opportunity to appreciate the struggles, hardships, and triumphs women have experienced to get to where they are today.

Women have been advocating for themselves for centuries. With every legislative act and cultural challenge, women continue to break through the glass ceilings that have oppressed them. And although they have made great strides, there are still areas where women are underrepresented, such as in manufacturing.

NRTC Automation offers several solutions to these challenges below. We also feature several of our own women employees to inspire future generations of women to join the manufacturing industry.

Women’s History Month

Honoring women’s journey to independence

In the last few centuries, there have been amazing leaps of progress in the journey to equality and independence.

From the suffragettes in the 19th and 20th centuries to the women's liberation movement in the 1960s and ‘70s to the #MeToo movement today, women are making great strides to achieve the equality they deserve.

There is still much work left to be done, however.

The challenge to encourage women in manufacturing

There is a clear difference in the ratio of women to men in the manufacturing workforce. Women make up less than one-third of the manufacturing industry in the United States, whereas half of Bachelor's degrees come from women.

How do we get women to join the manufacturing workforce? Could this be the way to decrease the two million unfulfilled jobs caused by a skills gap in the industry?

Methods to encourage women to apply to manufacturing jobs include:

increasing visibility of women on manufacturing teams, such as quality team leads and operators

ensuring that women have work/life balance and programs to support their careers, such as maternity leave and continuing education

minimizing the gender pay gap to provide women with the pay they deserve for the skills they bring to the table

providing ways for women to report sexual harassment in the workplace, and taking them seriously when they do report it

Manufacturers benefit when they hire women by gaining increasingly diverse perspectives, particularly for decision-making and problem-solving. Also, attracting and hiring women manufacturing workers will help decrease the skills gap that is currently plaguing the industry.

Looking toward the next generation of young women is key to bringing more women into the manufacturing workforce. Hosting events like plant tours and mentoring women through internships are both great ways to encourage women to join manufacturing facilities.

Also, nurturing girls' skills in STEM and encouraging them to express their interests in STEM in grade school and high school will set up the manufacturing industry for success.

Women who work for NRTC

In honor of Women’s History Month, NRTC Automation is featuring the wonderful women who work in our warehouse.

TOSHA HORNBUCKLE, QUALITY TEAM LEAD

Tosha Hornbuckle is the Quality Team Lead at NRTC Automation. She has been in the automotive industry for 10 years, starting as an operator in the assembly process. She later specialized in Class A Surface Inspections and metal finishing liaising for Mercedes and Kamtek. Tosha has also worked as a Quality Supervisor for a stamping company.

At NRTC, Tosha is focused on assuring that we produce quality parts in a safe work environment. She is the person to turn to when quality issues arise in the assembly process, and she also assists the management team with ideas to become more efficient in daily operations.

We asked Tosha what challenges she has experienced as a woman in a male-dominated industry. She says, “It can be a very competitive environment. You must be assertive and consistent and stay sharp. Make your skills and abilities count!”

Outside of NRTC, Tosha is a supremely accomplished woman with diverse interests.

Tosha loves to sing (and is quite good at it, too!).

She describes herself as a devoted wife and mother.

She is a certified life coach and wellness coach, as well as an author of the book, Finesse Your Fine: Transforming Your Life Heart, Mind & Body.

Not only that, but Tosha also runs a podcast with her husband called Heart 2 Heart, touching on relationships and life purpose.

Tosha’s favorite thing about working with NRTC is being able to bring her ideas to the table and helping our customers grow their business: “I enjoy being a part of cultivating a work environment that will set the company up for success.”

Ultimately, Tosha’s drive for success and helping others achieve their goals, both personally and professionally, make her a great fit at NRTC Automation.

ERICA HOOKS, SHIPPING COORDINATOR

Erica Hooks works in shipping for our Service Parts department, providing our customers with the parts they need, when they need them.

She worked in healthcare for 15 years before starting her first warehouse job at Auto Car as a material handler. After proving herself with hard work, self-education, and determination, she was promoted to shipping coordinator. Despite her promotion, Erica struggled to be respected by her male coworkers. She had to do heavy labor late into her pregnancy, and, unable to get the help she needed from her team, she ended up having an early labor. Thankfully, her 1-year-old son is now a healthy 28-pound baby.

Erica has a very different experience working at NRTC. She says that she has the “best supervisor” and couldn’t ask for a better person to lead her team. Her other team leads and managers make her feel like her work is appreciated, and she feels like she’s “finally a part of a team.”

Every day at NRTC Automation, Erica communicates with drivers, from UPS to FedEx to truck drivers, to make sure all incoming and outgoing packages are accounted for. She communicates with the team and stays on top of NRTC’s goals with a daily morning meeting to go over work objectives.

According to Erica, working in a male-dominated field can be intimidating. She says, “I feel like I have to work extra hard just to prove I belong. I have to stand firm on whatever I believe in.” This perspective is common for many women in any male-dominated field. Even though she loves the atmosphere at NRTC—it is a very family-oriented environment, she says—being a woman in a mostly-male environment has its challenges.

What are some fun facts about Erica?

She is a die-hard Alabama fan. In her own words, “ROLL TIDE!”

Erica is a proud sports mom of two teenage boys and one pre-teen boy. Her sons play basketball, football, and baseball, and she loves being able to watch and support their interests.

She has a strong relationship with her loving husband who helps her weather any phase of life. She says, “He’s my calming spirit to any storm I face; he always lets me know we got this.”

Overall, Erica is an enthusiastic and down-to-earth mother, wife, and NRTC team member, giving her best in every area of her life.

NRTC appreciates the diligent women on our team

The women who work for NRTC are valued members of the warehouse, offering their insights, experience, and expertise to help us provide the best service possible.

With Tosha and Erica, as well as all our employees at NRTC, we give our customers the service that we’ve been recognized for by partners like Toyota, Mercedes, Ford, and more. Join us to meet your production goals by scheduling a free consultation today.

VISIT NRTC AUTOMATION TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website today to learn more about our comprehensive decommissioning and automation services.

3 Signs That Your Robot Needs Repair

Taking care of your robot is easy when you practice preventative maintenance. However, there comes a point when your robot might need more for optimal performance.

Taking care of your robot is easy when you practice preventative maintenance. However, there comes a point when your robot might need more for optimal performance.

Industrial robots are the heart and soul of automation. They need to be in prime condition at all times to operate efficiently and effectively.

The best way to do this is through preventative maintenance. However, even the most well-prepared manufacturer will have to repair their robot eventually.

Learn more about the signs that your robot needs repair and how NRTC Automation can help below.

3 signs that your robot needs repair

Preventative maintenance

Across the board, preventative maintenance (or PM) in manufacturing is the number one way to protect your equipment, extend equipment useable life, and increase cost savings over time.

Every manufacturer should be proactive about PM. By rigidly adhering to maintenance schedules, business owners can see a 545% ROI on their equipment. You read that right! Although maintenance involves some costs of cleaning and replacing parts, the ROI is well worth the small price.

We can help maintain your equipment. You can choose your level of reconditioning based on the condition and hourly usage of the robot. NRTC Automation’s Industrial Robot Refurbishing Services will clean, grease, and test your equipment all the way up to a brand-new paint job and full robot restore.

Time for repairs

If your robot is older, or if you haven’t been diligent about maintenance, then it might be time for repairs.

While you may be tempted to skip the repair expenses, there are downsides to running your equipment into the ground:

Safety: This is the most important issue when considering maintenance and repair. When a robot isn’t functioning properly, it becomes unpredictable and could potentially hurt or fatally injure your employees.

Electrical damage: Electrical damage can occur in a malfunctioning robot due to worn cables and other equipment. This can create dangerous conditions on the production line.

Unplanned downtime: If your robot dies suddenly, the unplanned downtime can cost thousands of dollars a minute. And if you don’t have a technician in-house, getting someone in to fix it can take a while.

Product quality issues: Robots need to be in tip-top shape to ensure that your product is consistently made well. Without maintenance or repairs, your robot could potentially end up ruining hundreds or even thousands of products before you realize it.

Keeping up with your robots is a necessity for the well-being of your employees, your production line, and your bottom line.

3 signs that your robot needs repair

How do you know when it is time for a repair? Check out these three signs to determine if you need to get your robot to the nearest technician.

1. DOWNTIME

You’re doing everything you can to increase productivity, from implementing lean manufacturing methods to automating additional processes, but for some reason, your numbers just aren’t reaching the markers.

Have you checked how your robot is performing? If an industrial robot needs repair, then it could be contributing to your downtime. Faulty controls, software, and other systems can cause a robot to slow down and move erratically, wasting precious production time.

2. REPEATABILITY

Robots need to have highly repeatable applications to produce high-quality products. For example, if you have a welding robot, you want your welds to be precise and clean.

However, if your robot needs repair, your welds might come out sloppy, erratic, and generally unfit for consumer use.

Keep an eye on your robot’s output to ensure that it meets your standards. If not, it may be time to send it to the technician.

3. ENERGY EFFICIENCY

Finally, industrial robots should be as energy-efficient as possible. When a robot starts using a lot of energy, it is a sign that the parts aren’t working properly. Not only does this affect the overall productivity of the robot, but it is also a strain on your wallet.

Check on energy usage reports to determine where electricity and other energy sources are being used the most.

Get expert repair services at NRTC

NRTC Automation offers both Engineering Services to troubleshoot and diagnose your robot as well as Industrial Robot Refurbishing Services to maintain your equipment for a well-rounded automation experience.

Plus, our sister company, iGAM, provides refurbished robot parts and equipment so you can repair your industrial robot without breaking the budget.

Don’t delay fixing your equipment! Save on downtime and expensive product recalls by contacting NRTC Automation today.

VISIT OUR WEBSITE TODAY

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us to meet your production goals this year.

What Changed in Industrial Automation in the Age of COVID-19?

The whole world experienced a massive shift after COVID-19 struck. The manufacturing sector was no exception.

The whole world experienced a massive shift after COVID-19 struck. The manufacturing sector was no exception.

Before the pandemic, industrial automation was slowly growing into the 4th Industrial Revolution, or Industry 4.0. After the global shutdown, manufacturing and other industries were ushered into a new era of technology dependence.

Industrial automation became the hot topic of 2020. Manufacturers who previously used traditional production methods and survived the pandemic are highly encouraged to adopt automation to stay relevant with global competition.

Learn more about how COVID-19 changed manufacturing and industrial automation, as well as how you can automate your production line, below.

Industrial automation during the COVID-19 pandemic

COVID-19 rocked the world

When coronavirus started making headline news in February 2020 and shut down the world by March, researchers, publications, scientists, and other thought leaders surmised how a global pandemic might affect the manufacturing industry.

The outlook was a mix of positive and negative:

Some looked at the pandemic’s effects on the workplace and saw the perfect opportunity for industrial robots to maintain social distancing mandates and clean workplaces.

Others feared that the drops in profit and productivity at the beginning of the pandemic would forever scar the industry’s ability to bounce back.

There is truth in both of these predictions. Some manufacturing companies sunk because of COVID-19, unable to keep up with the struggles of closures, labor changes, and reduced demand.

However, this is a great moment for automation because it proves just how necessary industrial robots and equipment are to maintain our standards of living. During difficult and uncertain times, industrial automation allowed us to continue production while keeping workers safe.

Uncertainties abound

Even now, a year after the fact, there are still uncertainties around how life will look after COVID-19.

What will the “new normal” look like for the manufacturing sector?

Will industrial automation be handling even more processes than before?

Will employees shift to other labor like management, maintenance, and repair?

Will there be a resulting skills gap that is even larger than what manufacturing was experiencing before the pandemic?

What shifts will occur in IoT and cybersecurity to meet the new disparities and mitigate risks caused by these changes?

The answers to these questions will impact not only companies who want to continue growing during COVID-19, but also future manufacturing workers and the economy.

Hopefully, the insights gained from manufacturing’s weaknesses during the pandemic will provide industry leaders—as well as small manufacturers and their employees —with the opportunity to improve production processes and offer a better workplace and product all around.

Why you should automate during the pandemic

If you are a manufacturer struggling during the pandemic, we understand your concerns. You have survived one of the toughest fallouts in manufacturing since the Great Depression and the 2008 Great Recession. However, studies report that manufacturing has bounced back to pre-COVID levels and continues to look up into the spring.

Now is the time to act: automate your processes and keep up with the global competition. Manufacturers around the world are jumping on the Industry 4.0 bandwagon. If you continue with traditional manufacturing practices, you may find yourself on the outskirts of consumer demand.

Finance automation with us

Cost is always a concern, and NRTC Automation kept that in mind when designing automation solutions for our customers.

For those looking to automate specific production capabilities at an affordable price, robotic work cells offer the competitive advantages of an all-in-one package including:

maximum compatibility between components

increased efficiency

improved safety

Not only do we provide affordable custom work cells by using refurbished industrial robots and equipment, but we also offer financing so manufacturers of any budget can automate their warehouse.

To learn more about our financing options for your specific automation needs, schedule a free consultation with NRTC Automation. We’ll go over the cost, design specifications, engineering, and installation questions you may have about your custom work cell.

DON’T JUST SURVIVE, THRIVE WITH NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Contact NRTC today to meet your production goals during these challenging times.

Meet Joey Marimberga!

This Employee Spotlight shines on Joey Marimberga, our Senior Robot Programmer and Technician for our Service Parts department.

This Employee Spotlight shines on Joey Marimberga, our Senior Robot Programmer and Technician for our Service Parts department.

Since technology is constantly changing, staying on top of industrial robot trends and knowledge is a challenge.

That’s why it’s important to continue to learn by working with many different robot manufacturers and educating yourself with certifications.

That’s exactly what Joey Marimberga, our Senior Robot Programmer and Technician, does to offer our customers the best service possible.

Learn more about Joey and his work with NRTC Automation below!

Joey Marimberga, Senior Robot Programmer and Technician

Background

Prior to joining NRTC Automation, Joey worked as an integrator mostly in OEM plants. He integrated entire body shop lines, assisting with everything from robotics engineering to welding. Joey has installed over 500 robots during his time working for these large automotive companies.

Some examples of companies he has worked with include:

Tesla

BMW

Chrysler

Mercedes

Ford

General Motors

Joey also has certifications in advanced programming in KUKA robotics, FANUC robotics, and ABB robotics. He also has an intermediate certification for Comau robots.

His experience working with the listed corporations, as well as his certifications, makes him a perfect fit to assist our customers with their engineering needs.

Working at NRTC

Joey began working for NRTC Automation full-time in July 2020 as our Senior Robot Technician and Programmer. He started as a contractor and, after working on a project in South Carolina, was invited to join the company in his current position.

What does a day in the life at NRTC Automation look like for a Senior Robot Technician and Programmer?

Joey says that he never stops moving. He oversees all the robot technicians that work for NRTC, meaning he spends a portion of his day managing their work assignments. He also assists with all troubleshooting services.

Joey has a wide range of experience in working with robots. He can diagnose and troubleshoot the following models:

Comau

Motoman

In addition to the tasks above, Joey will help with mechanical and electrical tasks. He is the person to turn to when robotic payload or reach is in question.

Joey's method to diagnose a robot

When it comes to diagnosing and troubleshooting a robot, Joey has a process that he follows. It differs depending on the age and type of robot, but the general procedure is the same.

Power up: The robot must turn on and communication must be active between the cabinet and the robot. He also looks for encoder and motor values from the robot, meaning the robot should be able to move.

Software: The software should be applicable to the robot’s application, such as welding, material handling, or gluing.

PLC and other devices: Communication should be established between the PLC and any other device that the robot uses. The IO should be configured to make sure that it is all functional.

Joey says that he frequently finds that there are missing boards, cables, and other important parts, so he ensures that the robot has all the equipment it needs to function properly.

What is Joey’s most interesting project?

We asked Joey what his favorite project was that he worked on.

He responded that it must be the Tesla Model 3 project: “I did a glass marriage, which means we took rear quarter glass—it was encapsulated glass—and married all the trim onto it robotically. It's never been done before. This is something that's always been done by hand, and it's usually performed in Mexico and they ship it out to the customer.”

“However,” he continued, “we were able to automate it and we put it line side at Tesla for their Model 3. It's the only line in the world like it. So, I would definitely say that was probably the coolest project I've ever done because I can say I'm the only man that's ever done it.”

Plus, Elon Musk himself has praised Joey and his team about the line. We can imagine how exciting that would be!

Life outside of NRTC Automation

Joey not only excels as Senior Robot Programmer and Technician at NRTC, but he also lives an active life outside of work.

Joey used to be a professional athlete for several years. He was a combat athlete for 25 years, and now he coaches to share his knowledge of the sport with the next generation.

On top of being an athlete, Joey is also a former Marine Sargeant. The discipline, determination, honor, and enthusiasm that Joey showed for these passions carry into the services he provides at NRTC every day!

Tips for customers

We asked Joey what he suggests that customers should do to protect their equipment.

Above all, Joey recommends preventative maintenance to protect equipment and extend useable life.

Preventative maintenance, or PdM, is a regularly scheduled maintenance for equipment, including tasks such as inspection, cleaning, replacing robot grease, repairing parts, and more.

The maintenance schedule is listed in the equipment's documentation, so be sure to add it to your calendar so you don’t miss it.

NRTC Automation offers Industrial Robot Refurbishing Services so you can extend the life of your equipment with ease. Visit our website to learn more.

GET THE DIAGNOSTICS SUPPORT YOU NEED AT NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us today to learn how we can help you reach your production goals.

5 Methods for a Lean Manufacturing Process

Lean is the way of the future. Get on top of your production waste by trying out one or more of these lean manufacturing methods.

Lean is the way of the future. Get on top of your production waste by trying out one or more of these lean manufacturing methods.

Manufacturing continues to change with technology and new ideas, and so manufacturers need to stay abreast of these innovations to remain competitive in their industry.

Lean manufacturing is one of the most important developments in manufacturing history, and it continues to inspire big-name manufacturers like Toyota today.

To start going lean and improve your production processes, learn more about the history of lean and popular methods below.

Using lean manufacturing methods

What is lean manufacturing?

Lean manufacturing is a methodology that applies practices and principles to reduce waste, minimize downtime, increase cost savings, and produce sustainably.

Although there is evidence of lean manufacturing methods back in the 15th century, the first real application of lean was in Henry Ford’s production line in 1913. In the 1930s and after World War II, Toyota led the world in lean manufacturing, providing monumental lean philosophies such as 5S.

Since then, lean manufacturing has developed into innovative philosophies that have changed how we manufacture today.

Benefits of going lean

The reason why manufacturing companies continue to use lean methodology is because of the numerous benefits it provides. Some of these benefits include:

Reduced lead time: Efficient manufacturing reduces lead time, shipping your product out faster for higher customer satisfaction.

Improved product quality: Product quality is improved when wasted motions and materials are removed. Like Antoine de Saint-Exupery said, “Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away.”

Less product waste: As mentioned, lean manufacturing reduces product waste by removing unnecessary materials during the manufacturing process.

Minimal downtime: Less time is wasted during lean manufacturing since processes are more efficient.

Increased cost savings: Because product quality is improved, downtime is minimized, and fewer materials are wasted, manufacturers see an increase in cost savings when they go lean.

Sustainability: Lean manufacturing is far more sustainable than traditional manufacturing, which is a necessity for consumers who demand better from companies.

To reap the benefits of lean thinking, learn five different methods of lean manufacturing below.

5 methods for a lean manufacturing process

1. KANBAN

The purpose of Kanban is to manage workflow processes in a visual manner. Kanban is Japanese for “sign,” and it was developed by Toyota in the 1940s.

In order to add Kanban thinking to your production line, start implementing visual cues of the progress of your products on the warehouse floor. This could be a digital board or a physical board that includes categories such as “Ready to Start,” “Working,” “Waiting,” “Review,” and “Done.”

2. KAIZEN

Kaizen is a form of Japanese business philosophy meaning “continuous improvement” or “change for the better." This lean method focuses on holistically improving product quality, company culture, and production efficiency.

It is a cycle of progression that constantly analyses production inefficiencies to improve manufacturing. By tracking and measuring progress, manufacturers can create leaner production lines.

3. CELLULAR MANUFACTURING

Cellular manufacturing is applied to the layout of the manufacturing floor. It is the strategic arrangement of equipment and processes to reduce waste.

Before cellular manufacturing, the flow of production was jumbled up, jumping around from one place to another throughout the plant. Now, manufacturers use cellular manufacturing to provide a seamless workflow through layouts such as the U-shape, straight line, or inverted U-shape.

4. 3P

The Ps of 3P stand for Production Preparation Process. By eliminating waste through prototyping, manufacturers can improve product quality and minimize downtime on the production floor.

NRTC Automation provides prototyping services to help you create a leaner company. Reach out to us here to learn more about what we can do for you.

5. 5S

Last but not least, 5S is another popular method of lean. It stands for Sort, Set in Order, Shine, Standardize, and Sustain. This method of lean manufacturing also originated in Japan and centers efficiency around necessary versus unnecessary processes.

It’s similar to adding key hooks near your front door so you don’t lose your car keys. By putting everything in its place, manufacturers can reduce downtime and improve productivity.

Stay competitive in 2021 by getting leaner

To stay competitive in your industry, start implementing more lean methodology into your manufacturing processes. Not only will you see an increase in cost savings and productivity, but you’ll have happier customers and greater demand for your product.

OPTIMIZE YOUR PRODUCTION LINE WITH NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with NRTC to learn how we can free up time and resources on your production floor.

How to Hire Experienced Technicians for Your Business

Manufacturing may be in a hiring slump, but with these tips, you can find the right technician for the job.

Manufacturing may be in a hiring slump, but with these tips, you can find the right technician for the job.

Hiring is a risky business. It takes time to find qualified people for a job, and if you choose the wrong person, the results can be disastrous.

And that’s not to mention manufacturing’s current worker shortage.

Learn how to overcome these barriers to recruiting and hiring technicians below.

How to hire experienced technicians for your business

Difficulties of hiring in manufacturing

There is a shortage of qualified workers in manufacturing.

By 2030, the manufacturing industry will be short of 2.5 million workers. These hiring challenges create gaps in the workplace, making it difficult for manufacturers to meet their production goals.

The COVID-19 pandemic hasn’t helped, either. People fear unemployment during these uncertain times and are searching for industries with lower unemployment rates.

Despite common public fear, automation cannot take over everyone’s job. We need experienced, qualified individuals to help run our manufacturing facilities.

Importance of finding quality employees

Hiring Joe Schmoe off the street may close the gap in your production line, but it could cause far more pervasive issues throughout your facility.

Hiring unqualified workers can lead to these problems:

Lower product quality

Machine failure due to improper use or maintenance

Increased lead time

Work-related issues between employees

That’s why it’s important to find the right people for the job. You can save hundreds of thousands of dollars on unplanned downtime or product recalls by taking the time to select experienced individuals.

Steps to find experienced technicians for your business

If you are in need of technicians on the warehouse floor, take these four steps.

1. GET CREATIVE.

Dump the traditional recruiting methods like local paper advertisements for modern methods:

Social media advertising: Get on platforms like Facebook, LinkedIn, and Twitter to advertise your job. If you already have a following, you can target people who have already expressed interest in your company. If you don’t, create an account and start building your online presence with a job offer!

Online job boards: People have moved online to search for everything, from employment to housing. Post your job on sites like Indeed to reach an expansive audience.

Events: Since COVID-19, group gatherings have been limited and require face coverings and social distancing. However, if gatherings are allowed in your area, then host a hiring event! You’ll meet your applicants face-to-face and get a better idea of the people you are targeting.

These newer forms of job recruitment may be foreign to you, but they provide an easier way to access more people, including people who are qualified and interested in your job.

2. OFFER INCENTIVES.

Does your company offer a 401(k) match? What about free lunches on Fridays or parental leave?

All of these incentives will drive applicants to your job. People want to work in a place that honors their needs and wants.

If you don’t currently offer incentives such as the above, then start looking into some that your company can afford. Not only will you drive more traffic to your job application, but your current employees will be compelled to stay longer as well.

3. ASK THE RIGHT QUESTIONS.

You’ve gotten some applications and you are ready to interview. This is the hard part.

Know the right questions to ask, and how to ask them. Don’t give applicants an easy way out with a leading question. For example, "You’ve worked on KUKA robots, haven’t you?” is a leading question because it suggests that the applicant should say yes. Use open-ended phrasing like “What robots have you worked on in the past?” to get an accurate answer.

Additionally, be sure to ask questions that probe both hard and soft skills. You don’t want to hire someone with brilliant technical skills but lacks any communication skills. You can ask scenario-based questions to determine how a person will work with other people.

4. BE OPEN TO TRAINING THE RIGHT PERSON.

If someone checks nearly all your boxes, but they are missing one vital skillset, then consider training them. Putting time and resources into an employee who meets your criteria is a long-term investment.

For example, they may be highly capable at debugging and troubleshooting, but need help learning how to perform robot cleaning and degreasing. Training your employees will provide them with new skills and show them that you want them to stay in the company.

NRTC Automation offers Robotic Training Services to get your staff on the right track. Learn more about how we can tailor our training to your company here.

Start looking for the right personnel for your company

The best time to start recruiting is now. Take advantage of the tips listed above to find the right person for the job.

If you need technicians but lack the resources to recruit, NRTC Automation can help! Our Engineering Services will recruit, interview, and hire qualified technicians. We make it easy for you to finish the job with the right personnel.

Learn more about our Engineering Services today.

GET HIRING HELP FROM NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Schedule a free consultation with us to learn more about how we can help you achieve your production goals.

We've Achieved ISO 9001 Certification!

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing for our customers across the globe.

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing for our customers across the globe.

By outsourcing your assembly manufacturing, you can minimize downtime, reduce lead time, and improve efficiency on the production floor.

Outsource with a company you trust. NRTC Automation’s parent company, NRTC Alabama Inc., has achieved the ISO 9001 certification to provide you with reliable services.

Learn more about this certification and how it can benefit you below!

NRTC Alabama is ISO 9001 certified

What is ISO 9001?

ISO 9001 is a quality management certification developed by ISO, or the International Organization of Standardization.

This organization was founded in 1947 and has implemented over 23,000 standards in every industry.

Certifications are not audited and registered by ISO; rather, companies like Perry Johnson Registrars, Inc. (PJR) audit and register companies for ISO certifications.

To read the ISO definition of the ISO 9001 standard, visit their website here.

What are we certified for?

NRTC Alabama is ISO 9001 certified to provide service assembly manufacturing. We were audited by PJR for the quality management systems of this service.

The official description provided by the certificate from PJR states that we are certified to provide the following scope: “The Manufacture of Precision Machined and/or Fabricated Automotive Assemblies to Customer’s Designs, Specifications, or Requirements.”

We completed the audit process in just under a year in order to offer our customers the peace of mind that they are getting the best services in the industry acknowledged by international standards.

Benefits to our customers

Looking to outsource your assembly manufacturing? NRTC Automation aims to be your preferred partner for your industrial automation and manufacturing needs. With our recent ISO 9001 certification, we are the top choice to provide your assembly manufacturing services.

Our customers benefit from outsourcing to a certified company because:

We can consistently provide high-quality services that meet your demands

We are constantly improving our methods and services to enhance your experience with us

We are regularly audited to maintain our certification status, so you know that you are receiving services from a reputable and dependable company

We meet all requirements set by the ISO 9001 standard because we believe in giving our customers the best the industry has to offer. Work with NRTC Automation to outsource your service assembly manufacturing.

Why should you outsource your assembly manufacturing?

Whether you are a small manufacturer or an enterprise-level business, outsourcing your assembly manufacturing will help you meet your production goals.

Cost savings: Save on labor, energy, and overhead costs dedicated to your assembly manufacturing by sending it to us.

Efficiency: Cut out extraneous production to focus exclusively on your main goals.

Scalability and demand: Respond to greater demand with ease, allowing you to grow your business.

Innovation: You'll have the resources for new ideas and product development when you free up time, space, and money by outsourcing.

Don’t wait to get ahead of the competition and start growing your company. Schedule a free consultation with NRTC Automation today to get a quote for your production needs.

OUTSOURCE YOUR ASSEMBLY MANUFACTURING TO NRTC AUTOMATION

NRTC Automation is dedicated to providing high-value industrial automation and manufacturing equipment solutions to all its customers.

From decommissioning and tear out to industrial robotic training services to custom flexible work cells, NRTC is the key to integrate your workplace. With personalized training and custom-built designs, NRTC Automation is the destination for all your industrial automation and manufacturing equipment services.

Visit our website to learn more.

How to Stay Ahead in Manufacturing in 2021

“The present is theirs; the future, for which I really worked, is mine.” ― Nikola Tesla

“The present is theirs; the future, for which I really worked, is mine.” ― Nikola Tesla

Although the manufacturing industry experienced setbacks due to the COVID-19 pandemic, there is still an opportunity for growth.

2021 will prove to be challenging because it will require manufacturers to think differently about their production processes. New technologies and techniques are needed to stay competitive in the post-pandemic world.

Read below about common errors that cause manufacturers to fall behind, and tips to get (and stay) ahead in 2021.

How to stay ahead in manufacturing in 2021

What causes manufacturers to fall behind?

Falling behind in manufacturing means losing revenue and potential customers to competitors due to avoidable errors.

What are some of these avoidable errors?

Not integrating new technologies: Manufacturers who keep up with technology and industry trends stay afloat in the competitive global market. Manufacturers who do not will miss out.

Being disorganized: Organization is key to productivity and overall company health. A disorganized manufacturing company is likely to have more errors that can potentially cost customer relationships.